Surface treated copper foil and mehtod for preparing the same and copper-clad laminate using the same

A surface treatment, copper foil technology, applied in the field of copper clad laminates, to achieve the effect of enhancing adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

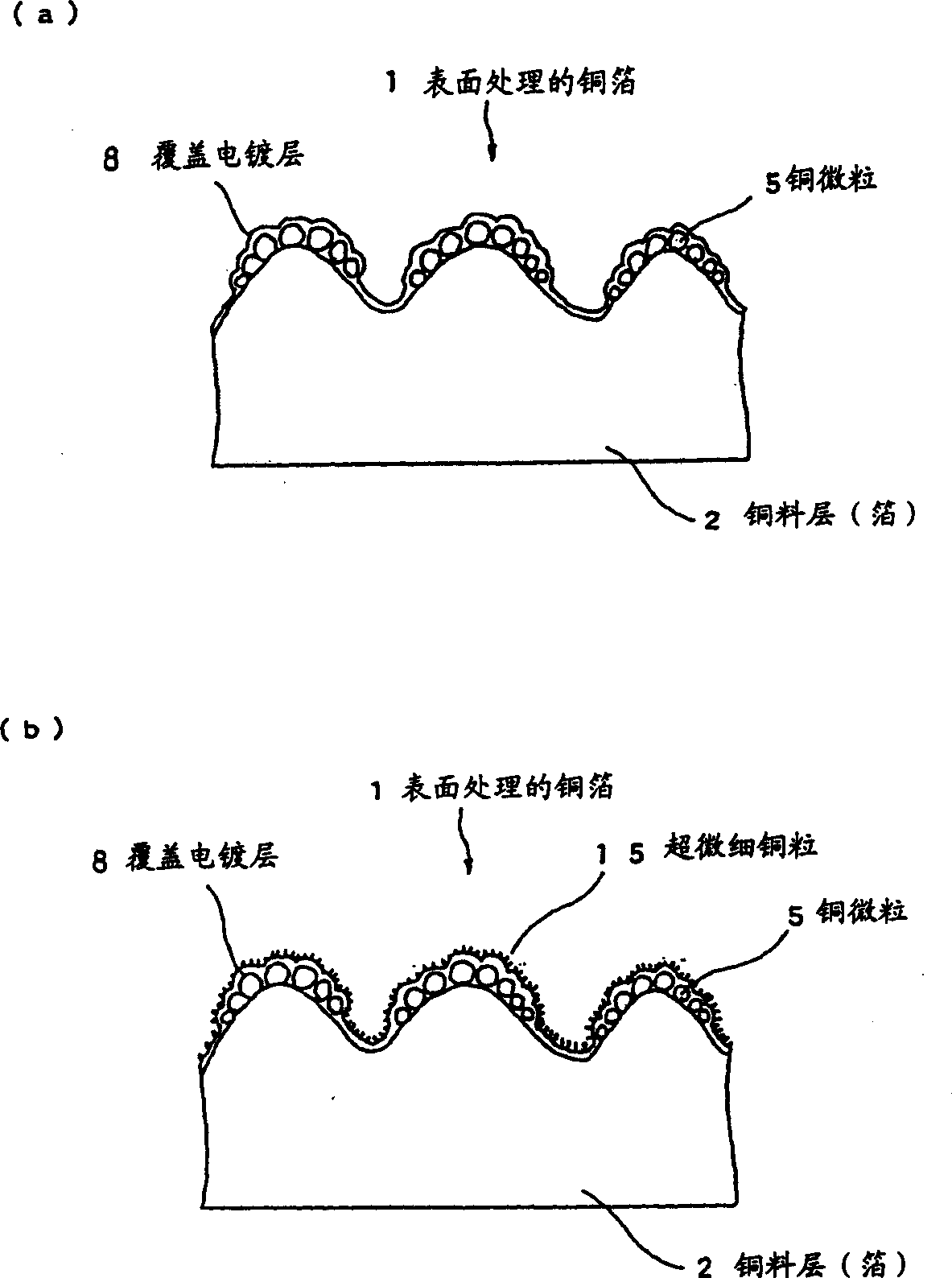

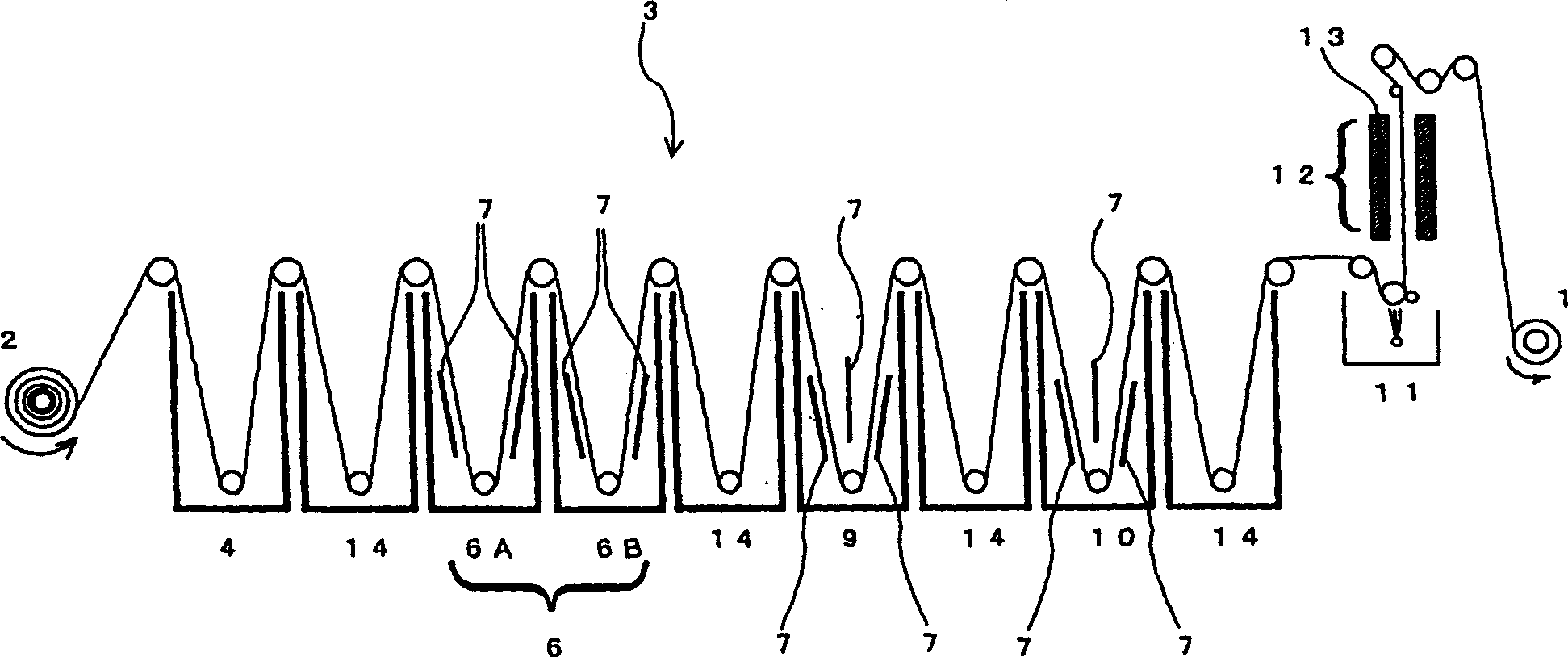

[0104] In Example 1, the surface treatment of the copper foil 2 was performed with the surface treatment device 3 . The copper foil 2 used was a roll of foil before surface treatment. exist figure 2 In the apparatus 3 shown, the copper foil 2 is unwound from a foil roll and travels through the surface treatment apparatus 3 in a circular fashion. A grade 3 copper foil having a nominal thickness of 35 µm was used as copper foil 2, thereby producing an electrolytic copper foil for use in the manufacture of printed wiring boards. In the following, the production conditions are described in connection with a plant having a number of tanks installed in series in succession. This embodiment will incorporate figure 1 (a) to illustrate.

[0105] The copper foil 2 unrolled from the foil roll is first sent to the pickling tank 4, which is filled with a dilute sulfuric acid solution at 30° C. with a concentration of 150 g / l. The copper foil was immersed therein for 30 seconds to rem...

Embodiment 2

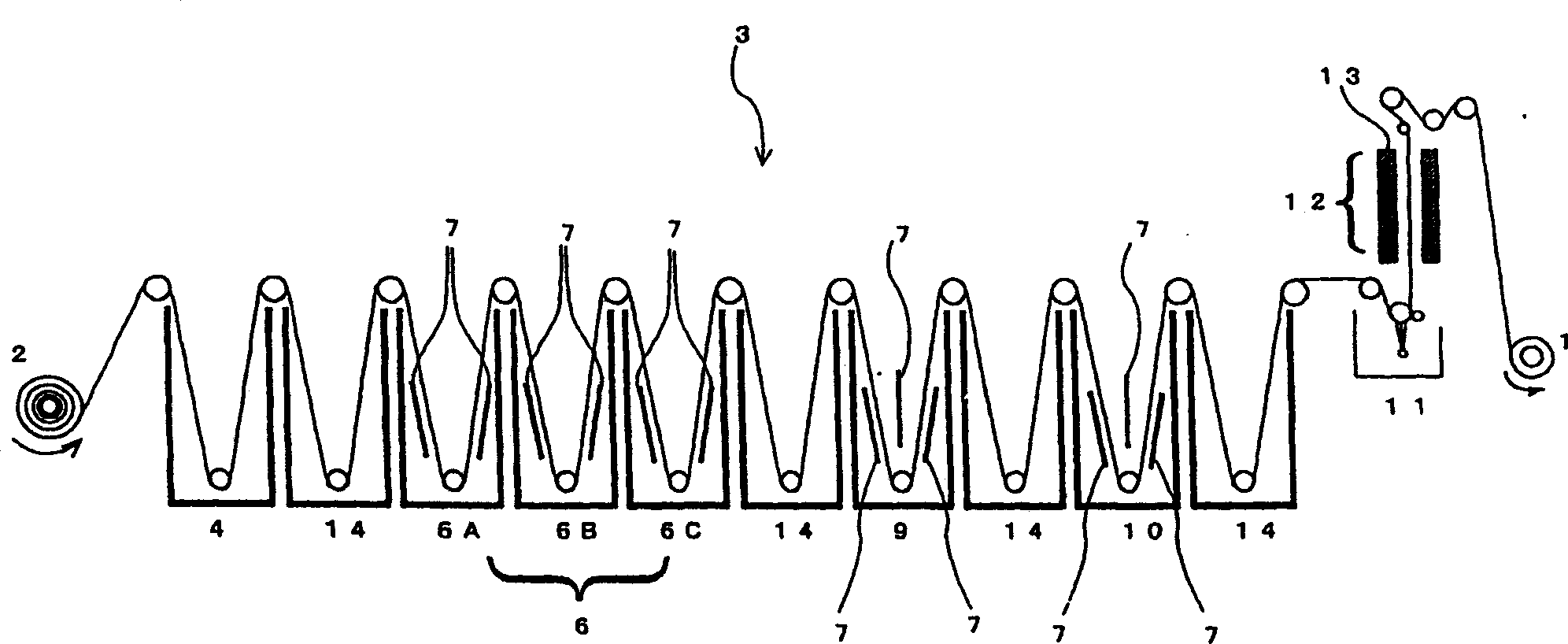

[0115] In Example 2, the surface treatment of the copper foil 2 was performed with the surface treatment device 3 . The copper foil 2 used was a roll of foil before surface treatment. exist image 3 In the apparatus 3 shown, the copper foil 2 is unrolled from a foil roll and advanced through the surface treatment apparatus 3 in a circular manner. A grade 3 copper foil having a nominal thickness of 35 µm was used as copper foil 2, thereby producing an electrodeposited copper foil for use in the manufacture of printed wiring boards. The production conditions will be described below in connection with a plant having a number of tanks installed in series in succession. To avoid redundant description, only those parts that are different from the corresponding parts described in Embodiment 1 are described. Whenever possible, the same parts as in Example 1 are in image 3 are represented by the same numbers. This embodiment will be combined with a section showing a cross-section...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com