Shape memory composition patch device for pipe connection

A memory alloy and memory technology, which is applied in the field of repairing pipeline structures and construction using shape memory materials, can solve problems such as unsolved problems, and achieve the effects of reducing the loss of transmission pressure head, simple space structure, and reliable sealing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

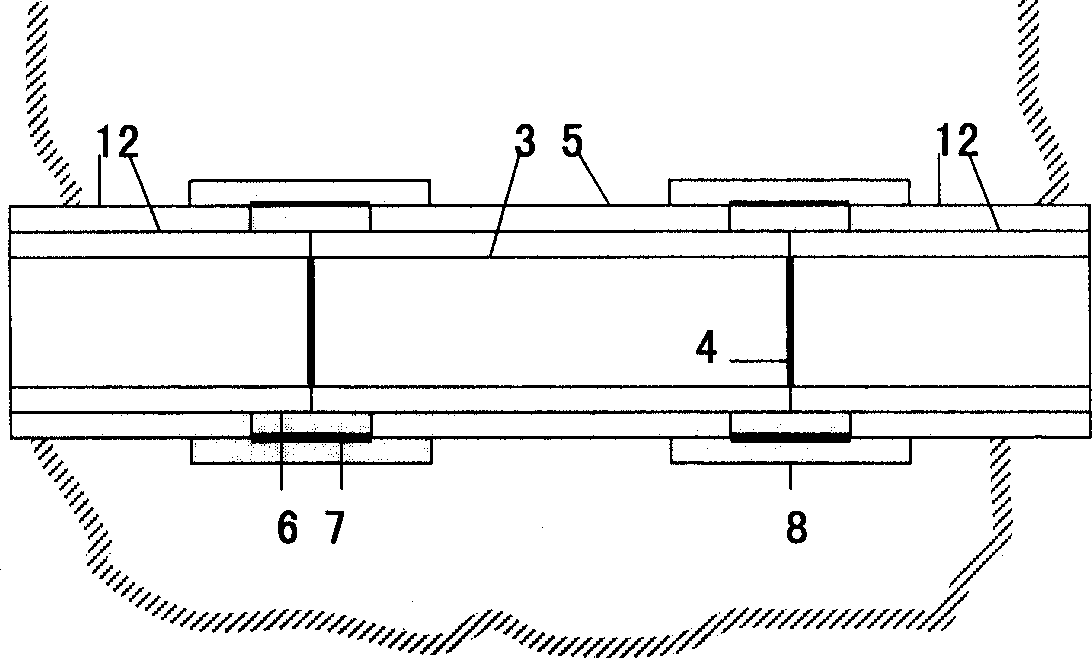

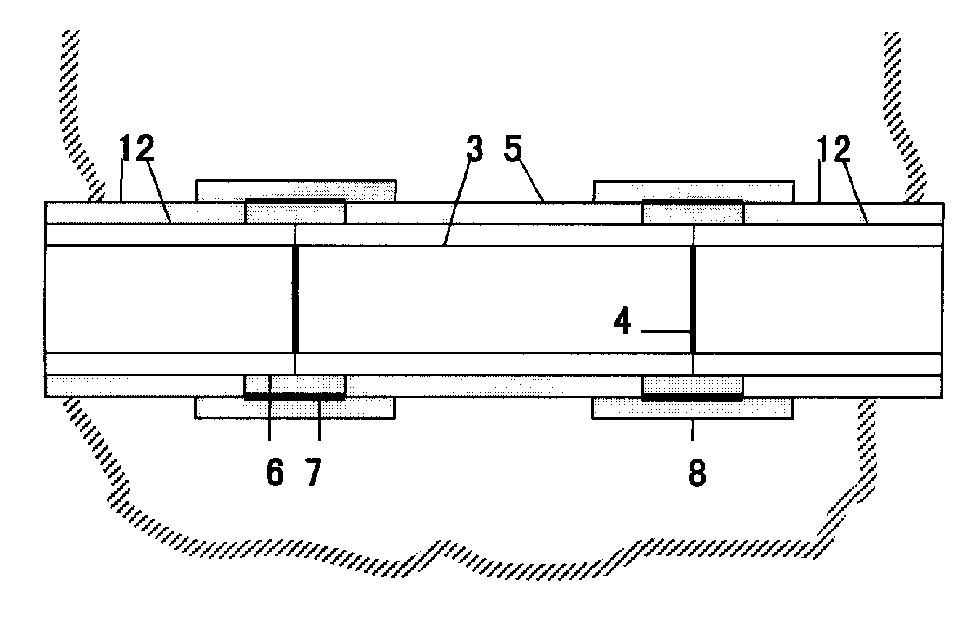

Image

Examples

Embodiment 2

[0011] The overhead high-pressure corrosion-resistant pipeline of Daqing Oil Refinery, the outer layer is G10, Φ156×3 carbon steel pipe, and the inner layer is 304 stainless steel pipe Φ150×2. Due to local leakage, cut off 10m in the middle. Make the stainless steel pipe at the cutting point of the original pipeline 30mm longer than the outer pipe, and put 100mm long iron-based shape memory alloy SM6 pipe sleeves on both sides. Take a new double-layer composite pipe 10 meters long. The carbon steel pipes at both ends are 30mm shorter than the stainless steel pipes. First weld the connecting stainless steel liner to the stainless steel liner on the left and right sides. Take two 59mm long, Φ156×3 G10 steel pipes, cut them in half axially, and make two sets of valve tubes. Put them on the welds on both sides respectively, and apply the sealing packing paste copper phosphate. Move memory alloy tubes to the position of valve tubes respectively, heat at 300°C for 3 minutes, shr...

Embodiment 3

[0013] In addition to using the shape memory joint to connect gas pipelines, it can also be used to connect water pipelines. Shanghai stainless steel pipe 0 Cr18 Ni8 Ti, Φ50×0.5, lined with PPR Φ49×4 high-rise water supply main pipe, which needs to withstand a pressure of 5MPa. Due to serving in a vibrating working environment, the original mechanical ferrule-type interface seepage occurred after 4 hours of operation. To connect the above-mentioned pipelines with the patching device of the present invention, first process the joints, grind away a little stainless steel, make the PPR liner protrude 3mm, insert the shape memory stainless steel sleeve, the length is 70mmΦ56×3, and control its inner diameter Φ50 positive tolerance. Use a fusion welder to weld the PPR pipe. In order to fill the excess space of the weld, wind the glass cloth tape so that the outer edge of the wound part is flush with the outer contour of the stainless steel pipe. Apply sealing packing fluororubber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com