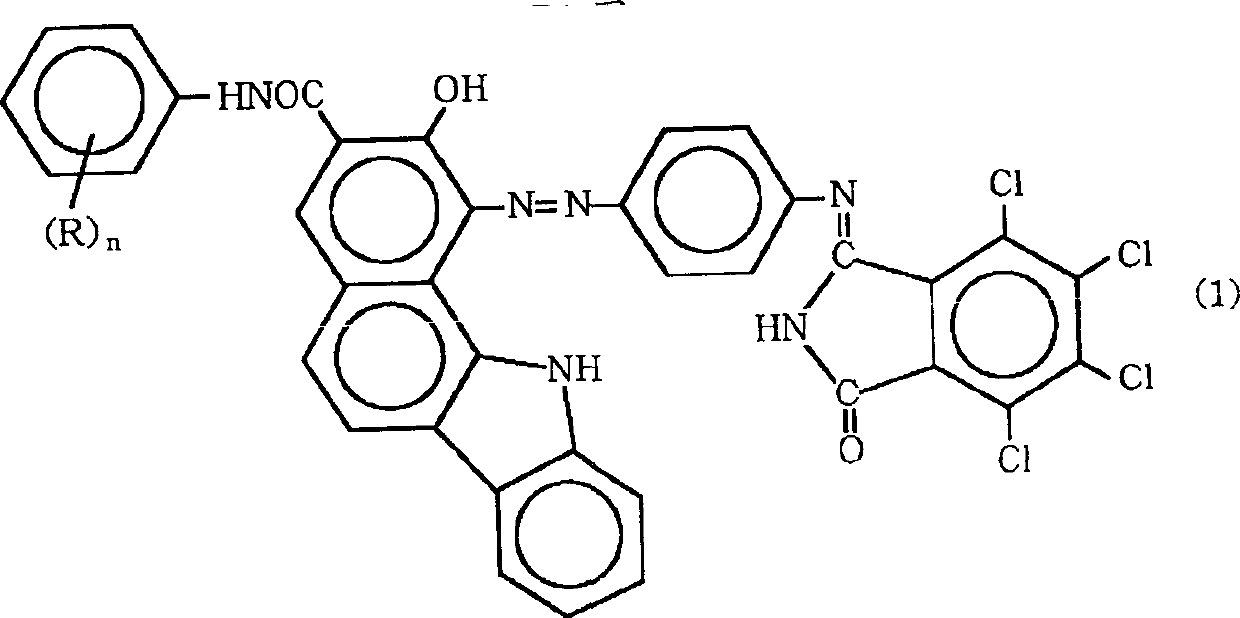

Near-infrared transmitting black azo-dye

An azo pigment and permeability technology, used in azo dyes, monoazo dyes, organic dyes, etc., can solve problems such as poor electrical insulation, unsuitable for coloring electronic components, and inability to improve, to prevent Illegal copying, temperature rise prevention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

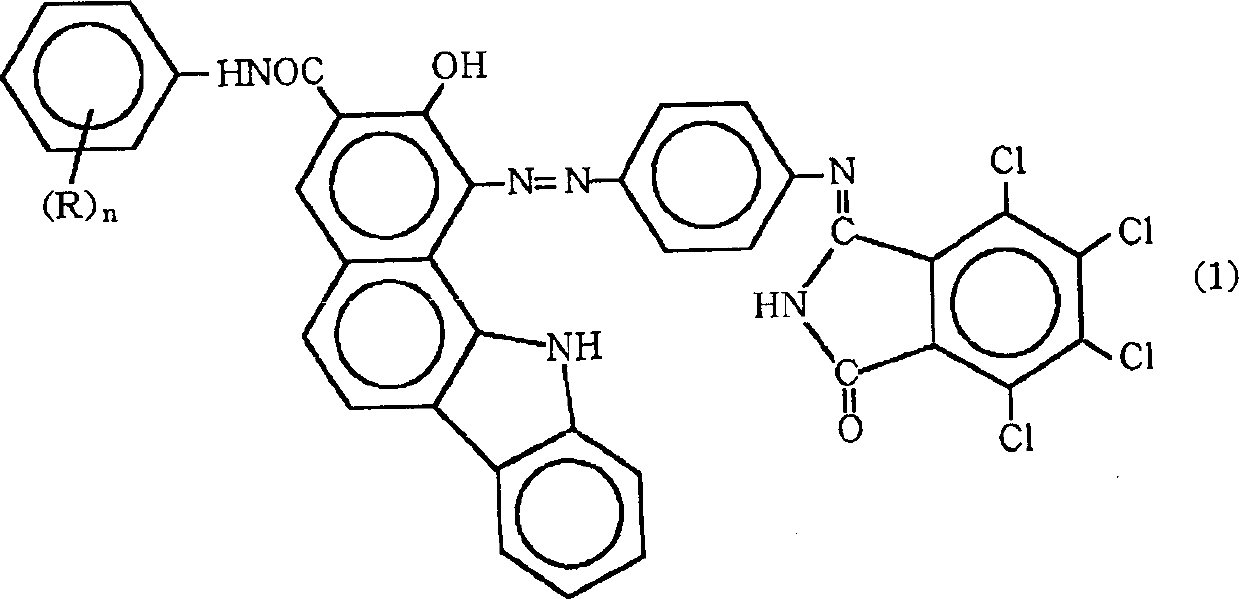

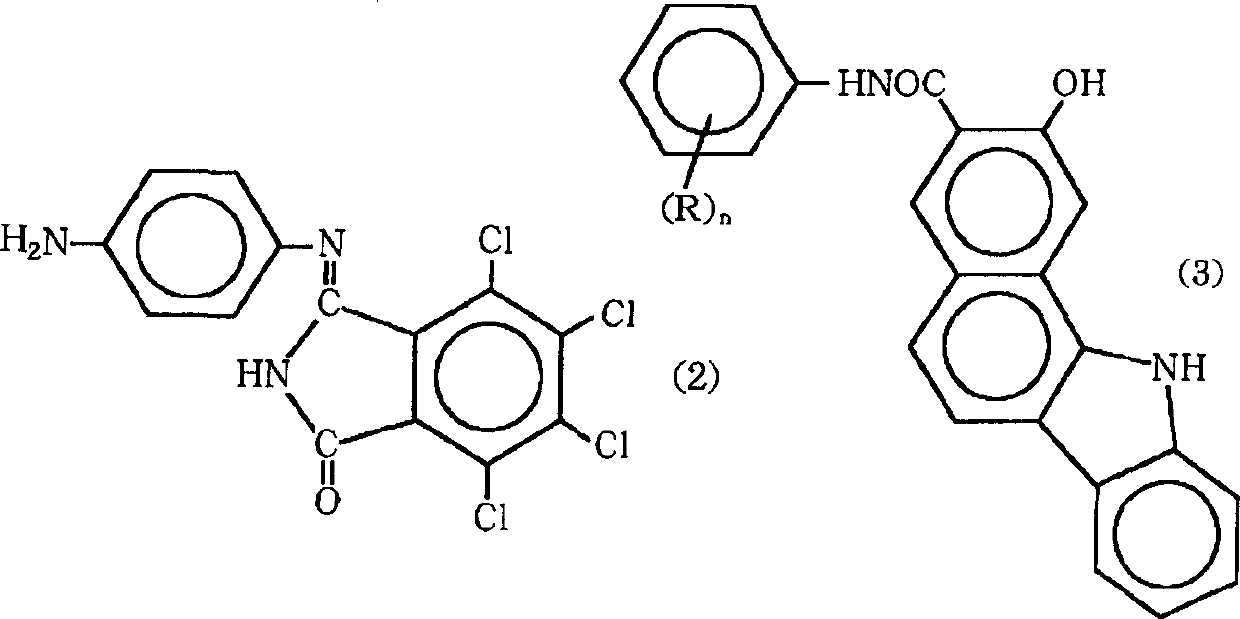

[0041] 3.75 parts (0.01 mol) of the compound represented by the above formula (2) were suspended in 11.3 parts of glacial acetic acid, and 3.7 parts of concentrated hydrochloric acid were added to the suspension, followed by stirring. Add 2.6 parts of water, keep the temperature at 0-5°C, add 2.0 parts of 40% sodium nitrite aqueous solution, and then stir at the same temperature for 30 minutes to obtain a yellow diazonium salt. Add 4.8 parts of sodium acetate trihydrate to the solution to prepare a diazonium salt solution.

[0042] On the other hand, 3.56 parts (0.009 mol) of the compound of general formula (3) wherein the phenyl has a substituent R of 2'-methyl-4'-methoxyphenyl is suspended in 250 parts of o-dichlorobenzene , Add the above-mentioned diazonium salt solution at 20-30°C to the suspension at 30-40°C, and then add 20 parts of glacial acetic acid. At the same time, the temperature was maintained for 5-6 hours for coupling, and then the reaction mixture was heated ...

Embodiment 2

[0045] 3.75 parts (0.01 mol) of the compound of the above formula (2) were suspended in 11.3 parts of glacial acetic acid, and 3.7 parts of concentrated hydrochloric acid were added thereto, followed by stirring. 2.6 parts of water were added to the obtained solution, and the temperature of the thus obtained mixture was kept at 0 to 5° C., and 2.0 parts of 40% sodium nitrite aqueous solution was added, followed by stirring at the same temperature for 30 minutes to obtain a yellow diazonium salt solution. To this solution, 4.8 parts of sodium acetate trihydrate was added to prepare a diazonium salt solution.

[0046] On the other hand, 2.77 parts (0.007 moles) of the compound of the above general formula (3) wherein the substituent R of the phenyl group is 2'-methyl-4'-methoxyphenyl and the substituent R of the phenyl group 1.53 parts (0.004 moles) of the compound of the above-mentioned general formula (3) in which R is 4'-methoxyphenyl is suspended in 250 parts of o-dichlorobe...

example 2

[0062] The above-mentioned coatings 1, 3 and 4 were respectively coated on an alumina plate (150mm×70mm×0.1mm) with a strip coater No.40, and dried by a known method in the prior art to make three kinds of black coatings 1 , 3 and 4. The above-mentioned 3 kinds of black smears 1, 3 and 4 are placed on the temperature rise test device made of foamed styrene, and each test piece is irradiated with light (250W infrared lamp) from the place 400mm away from the test board, and the test pieces are placed at 1, 3 and 4 respectively. 5, 10, 20 and 30 minutes to measure the temperature on the surface of the test piece and in the tank. The test results are shown in Table 3. Use the paint that contains the pigment of the present invention, the obtained smear 1, its transmittance of infrared rays is bigger than smear 3 and 4, thereby cause the reflection of aluminum oxide base plate to be big, compare with smear 3 and 4, smear 1 The surface temperature and the temperature in the tank ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com