Shaped corncob carbon and its making process

A manufacturing method and corncob technology are applied in the field of corncob machine-forming carbon manufacturing and corncob machine-forming carbon, achieving the effects of high strength, high calorific value and low investment in production equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

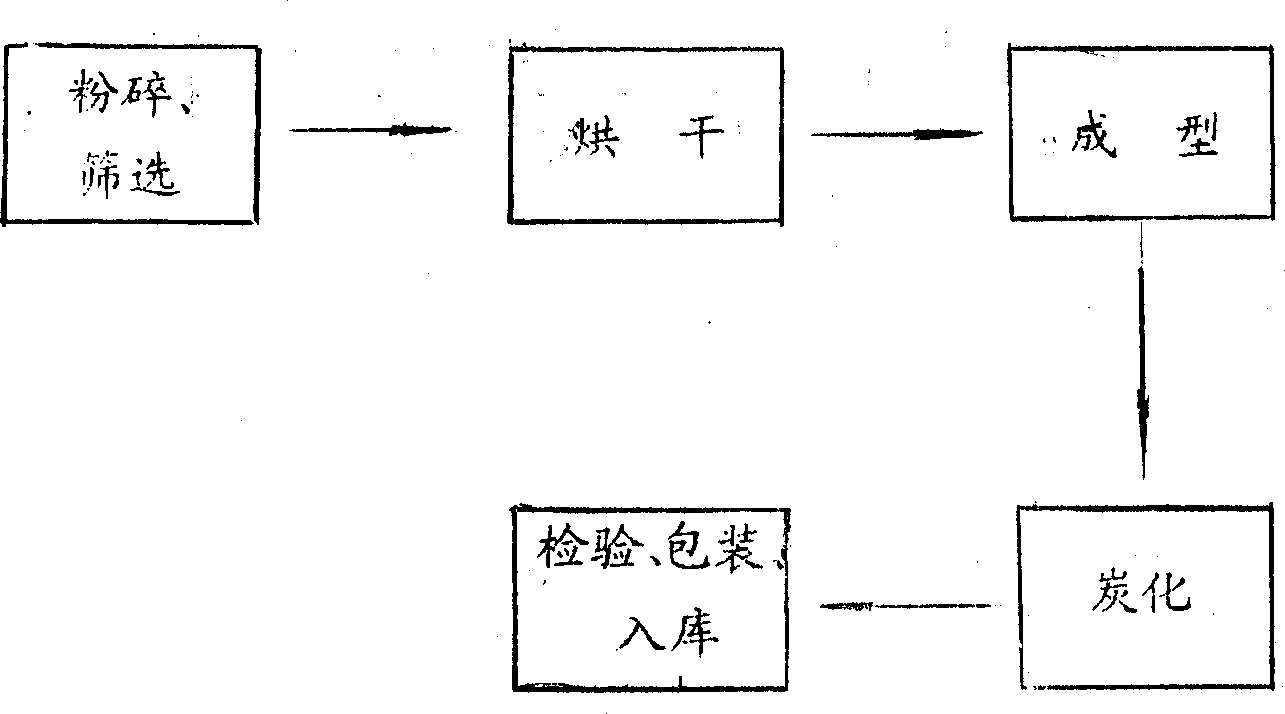

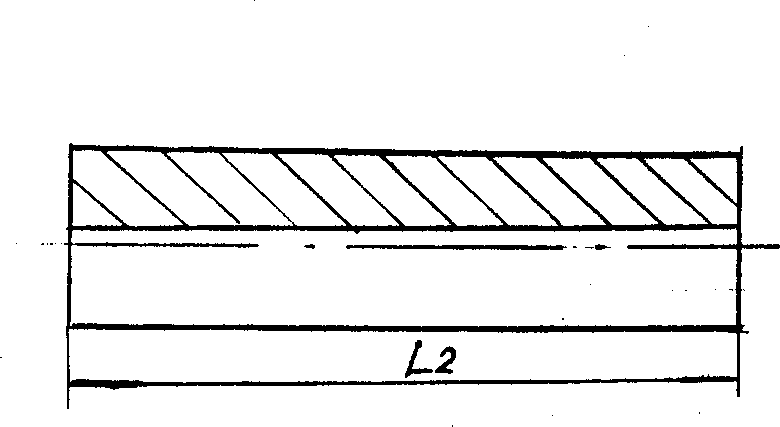

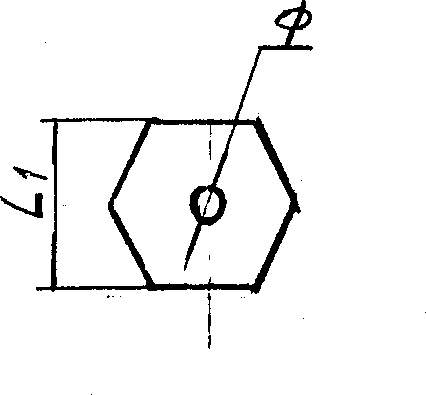

[0009] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. The manufacturing method of corn cob machine-made shaped carbon is: ①, crushing and screening: crush and screen the corn cob with a pulverizer, and make the granular shape with a size of not less than 0.5 mm and not larger than 7.0 mm; ②, drying: the granular The corncobs are sent to the hot air dryer for drying, the drying temperature is in the range of 120°C-280°C, and the moisture content of the corncob particles after drying is (10-16)%. The corncob particles are heated and pressurized in the molding machine to make semi-finished products of corncob machine-shaped charcoal. The heating temperature is 150°C-280°C; After burning for 120 hours, carry out anaerobic and atomization treatment. The anaerobic and atomization time is 48 hours to 96 hours, and then cool down to room temperature with the furnace; library. There are 3-8 edges on the overall ax...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com