Method and equipment for producing flexible cloth possessing hot melt adhesive coating layer applied by wire mesh

A technology of hot-melt adhesives and fabrics, applied in adhesives, film/sheet adhesives, printing of special varieties of printed matter, etc., can solve problems such as impossible to obtain a clean screen, excessive tension, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

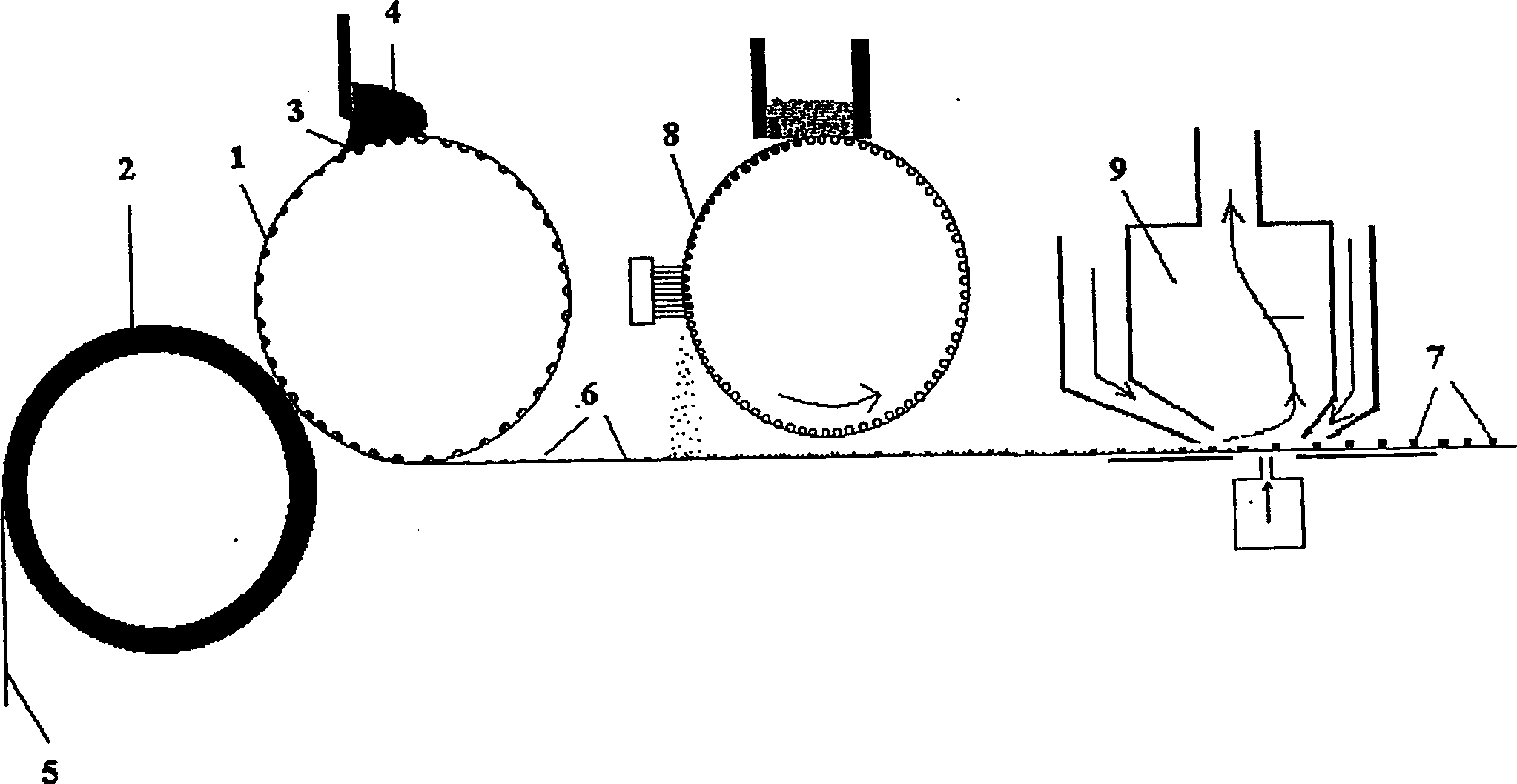

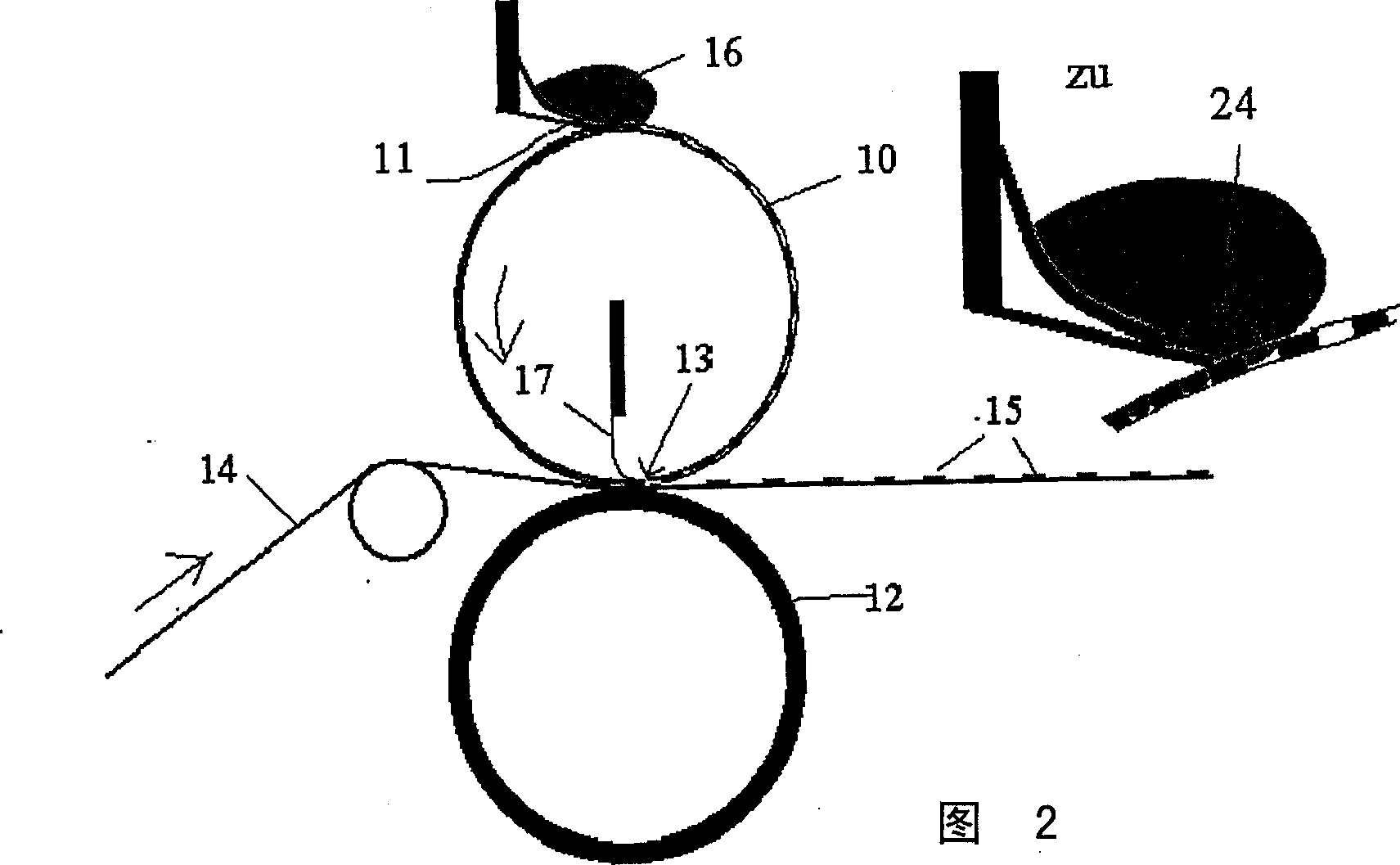

[0021] Embossing rolls and rubberized back rolls

[0022] - all cooled

[0023] - Embossed groove density: 80 / cm 2

[0024] —Embossed groove depth: 0.27mm

[0025] - Embossing depth: 0.18mm

[0026] Slurry composition

[0027] -PVC plus plasticizer 1:1:10%

[0028] - dry residue, cross-linked polymethacrylate 3.5%

[0029] - dry residue, additive 1%

[0030] - dry residue, thickener 2%

[0031] - excess water

[0032] Slurry viscosity: 15000-25000cP

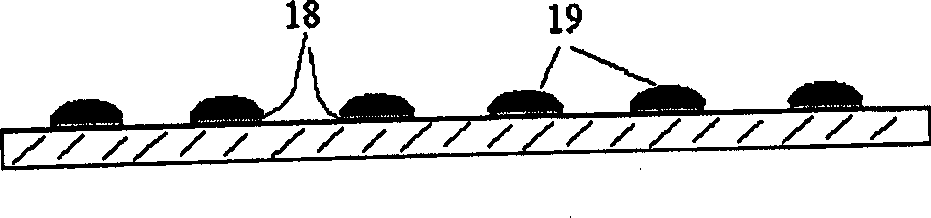

[0033] Hot melt adhesive powder: low melting copolyamide powder 80-160 m

[0034] Coated substrate: Braid 25g / m with textured polyester yarn 2

[0035] Coating weight: total weight 5.0g / m 2 , of which the protective layer is about 1g / m 2, hot melt adhesive about 4.0g / m 2

[0036] Coating error: + / -0.5g / m 2 (Sample 100cm 2 )

[0037] Adhesive strength (under the conditions of continuous material handling pressure, 127°C, set gap, polyester pullover outer material): better than 13N / 5cm

example 2

[0039] Bottom screen stencil, 150° obtuse external doctor blade and rubberized back roller

[0040] —Stencil hole density: 80 / cm 2

[0041] - Hole diameter: 0.30mm

[0042] - Wall thickness of bottom wire mesh: 0.19mm

[0043] - perforation drain of pores in continuous operation: about 60% of total pore volume (volume = pore cross-sectional area * Wall thickness of bottom wire mesh)

[0044] Slurry composition: same as above

[0045] Slurry viscosity: same as above

[0046] Coating error: same as above

[0047] Hot melt adhesive powder: same as above

[0048] Coated substrate: same as above

[0049] Coating weight: same as above

[0050] Adhesive strength: same as above

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com