Gas distribution apparatus for semiconductor processing

A technology for gas distribution and gas treatment, which is applied in the field of reaction chambers and can solve problems such as difficulty in uniform distribution of processing gases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Detailed description of the preferred embodiment

[0022] For a better understanding of the invention, the following detailed description refers to the accompanying drawings, in which there is shown and described a preferred exemplary embodiment of the invention. Furthermore, the reference numerals used to identify key elements of the invention in the figures are consistent throughout the figures.

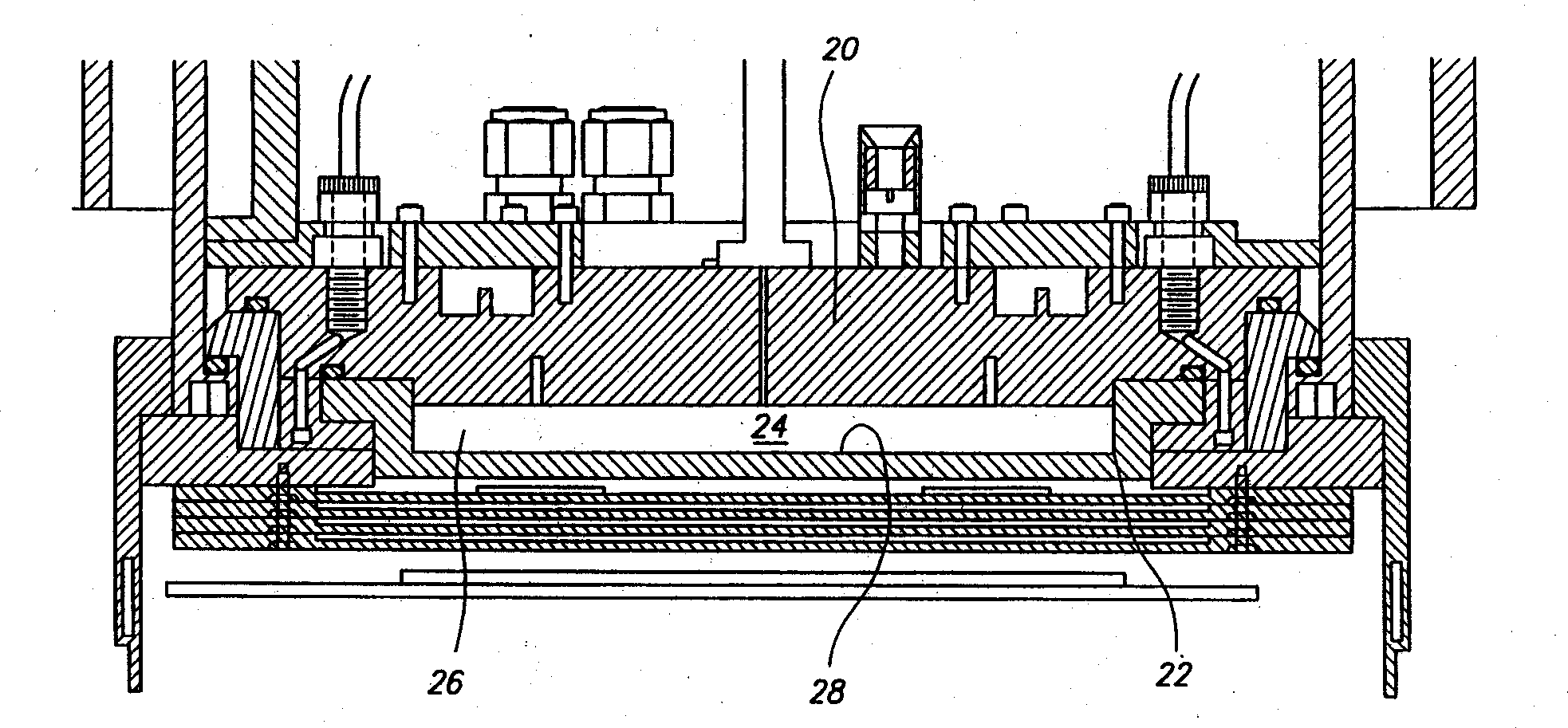

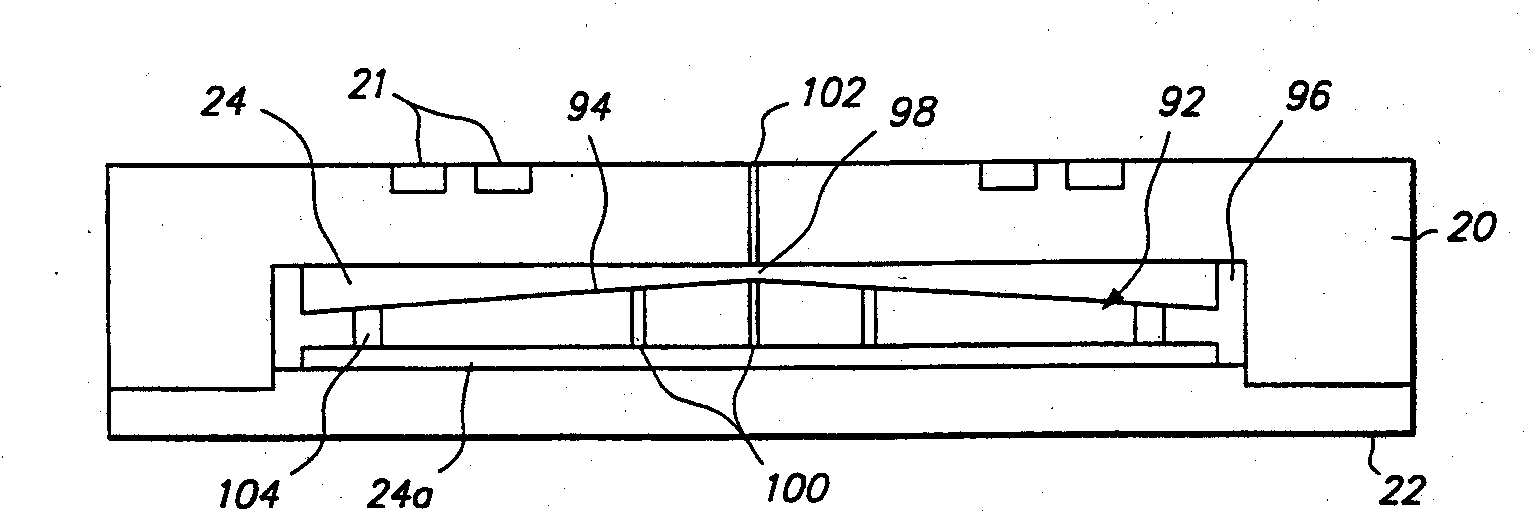

[0023] In accordance with the present invention, process gases can be uniformly distributed from one or more gas sources to a substrate located beneath a shower head. The present shower head can be used in any type of semiconductor processing equipment where it is desired to distribute process gases over a semiconductor substrate. Such equipment includes CVD systems, polishing equipment, capacitively coupled plasma reactors, inductively coupled plasma reactors, ECR reactors, and the like.

[0024] The gas distribution system for a parallel plate plasma reactor is shown in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com