Multi-element negative-expansion tungstate layer coated on microcrystal ceramics and its preparing process

A technology of microcrystalline ceramics and negative expansion, which is applied in the field of multi-component tungstate negative expansion microcrystalline ceramic coatings and its preparation, can solve the problems of interfacial stress hesitation, lack of compensation effect, difficult sintering and densification, etc., and achieve reliable Compensation effect, effect of good bonding characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

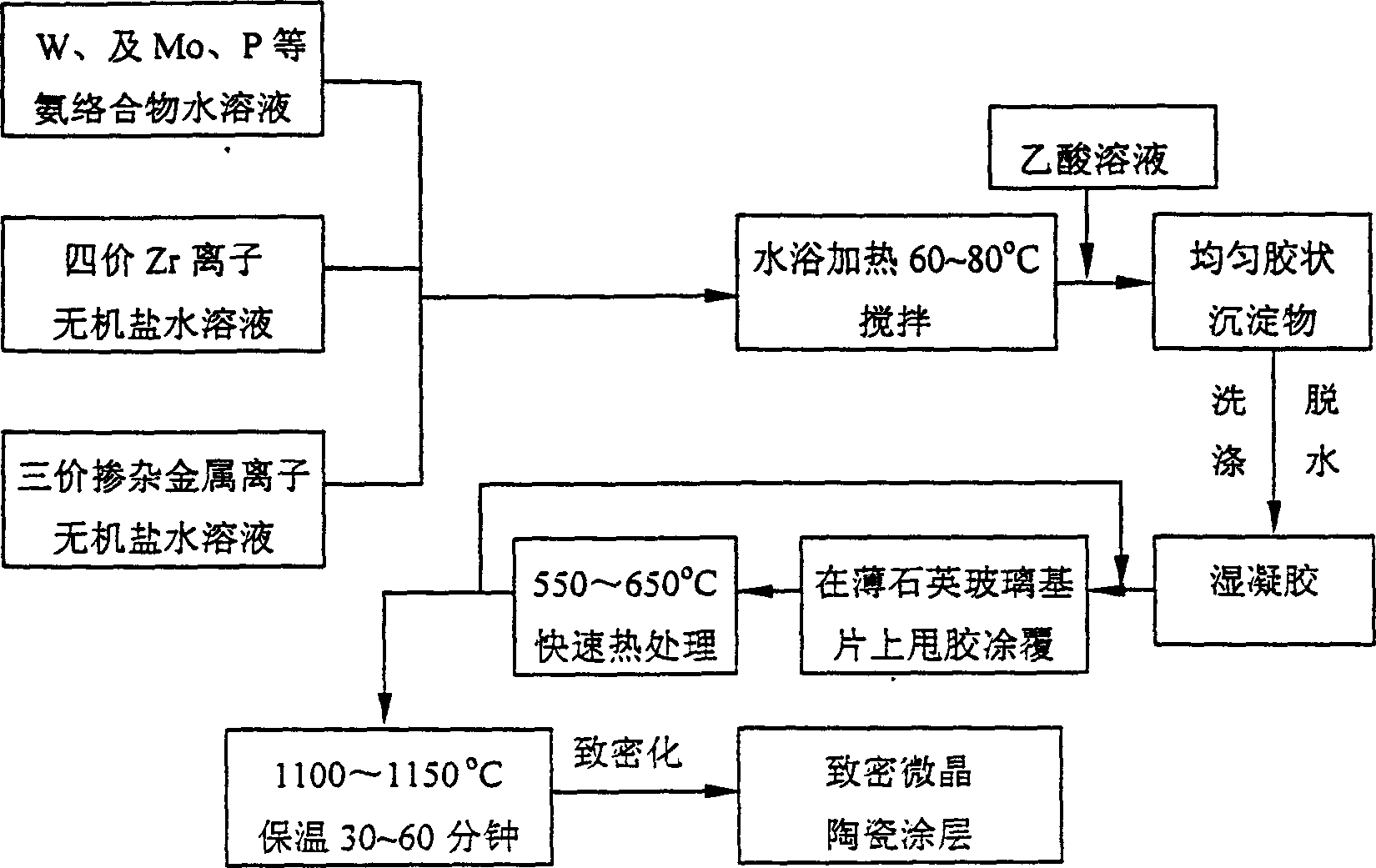

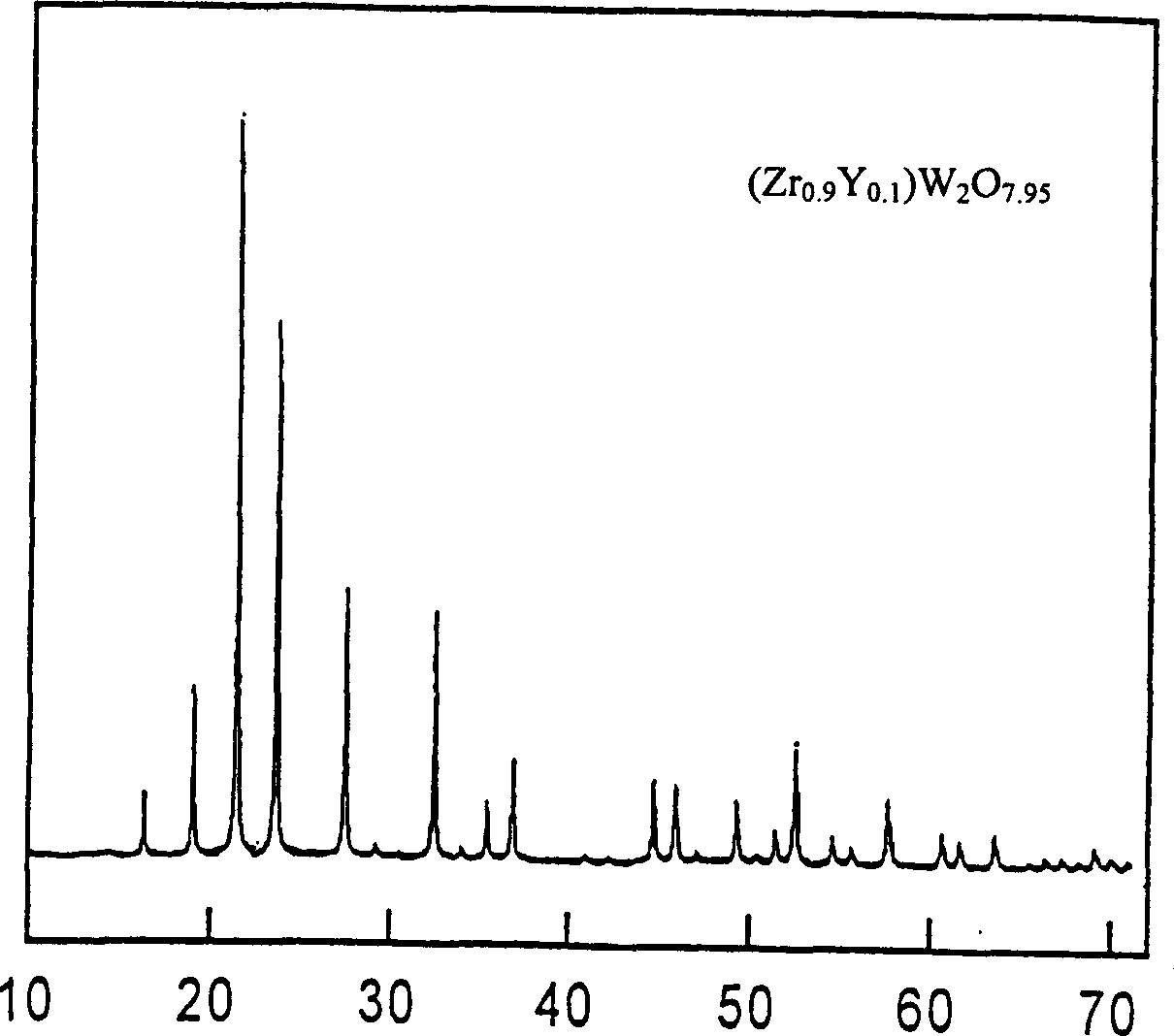

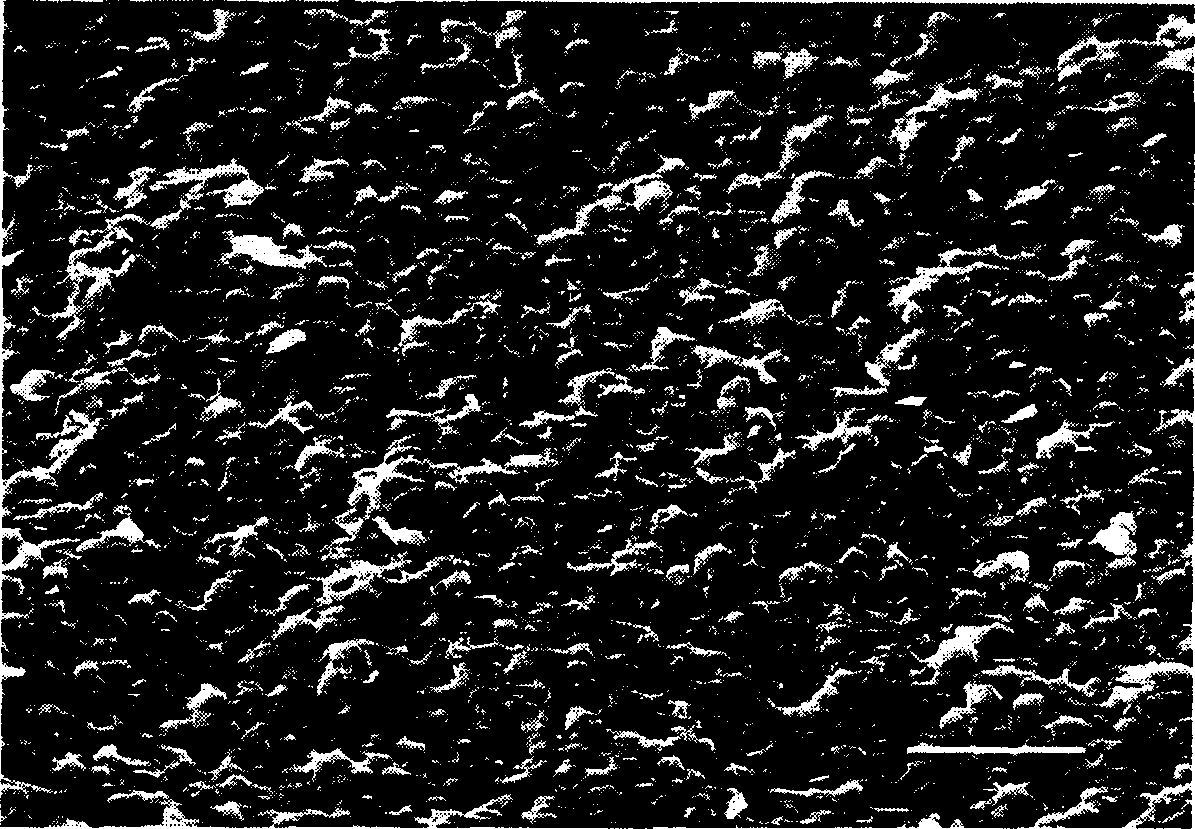

[0026] Take commercially available Y 2 O 3 Dissolve in nitric acid solution, configure to 0.1M Y(NO 3 ) 3 Solution, with commercially available ZrO(NO 3 ) 2 Configured as 1M ZrO(NO 3 ) 2 Solution, and configure 1M ammonia complex (NH 4 ) 6 H 2 W 12 O 40 As precursors, these precursors are mixed uniformly according to the atomic ratio of the metal contained in Y:Zr:W=0.1:0.9:2.0, heated in a water bath at 60~80℃ with constant stirring, and titrated 2M into the mixed precursor Acetic acid solution until a uniform colloidal precipitate containing multiple metal atoms is completely formed. After the obtained colloidal mixture is washed and dehydrated for many times, a wet gel is formed. The formed gel is spun on a thin substrate of near-zero expansion quartz glass with a thickness of 0.30~0.40mm, and is subjected to rapid heat treatment at 600°C for 5 minutes, and then multiple cycles of spun and rapid heat treatment. In one or two quartz glass The surface is deposited with a thicknes...

Embodiment 2

[0028] Commercially available AlCl 3 Configured to 0.4M AlCl 3 Solution to commercially available ZrOCl 2 ·8H 2 O configured as 1MZrOCl 2 Solution, use commercially available phosphoric acid to configure 0.5M phosphoric acid solution, and configure 1M ammonia complex (NH 4 ) 6 H 2 W 12 O 40 These precursors are mixed uniformly according to the atomic ratio of the metal contained in Al:Zr:W:P=0.04:0.96:1.96:0.04, and then heated in a water bath at 60~80℃ with constant stirring. Titrate the 2M acetic acid solution in the body until a uniform colloidal precipitate containing multiple metal atoms is completely formed. After the obtained colloidal mixture is washed and dehydrated for many times, a wet gel is formed. The gel is spun on a thin substrate of near-zero expansion quartz glass with a thickness of 0.30~0.40mm, fast heat treatment at 650℃ for 8 minutes, and then several cycles of spun and fast heat treatment, on one or two surfaces of the quartz glass It is deposited to a thick...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com