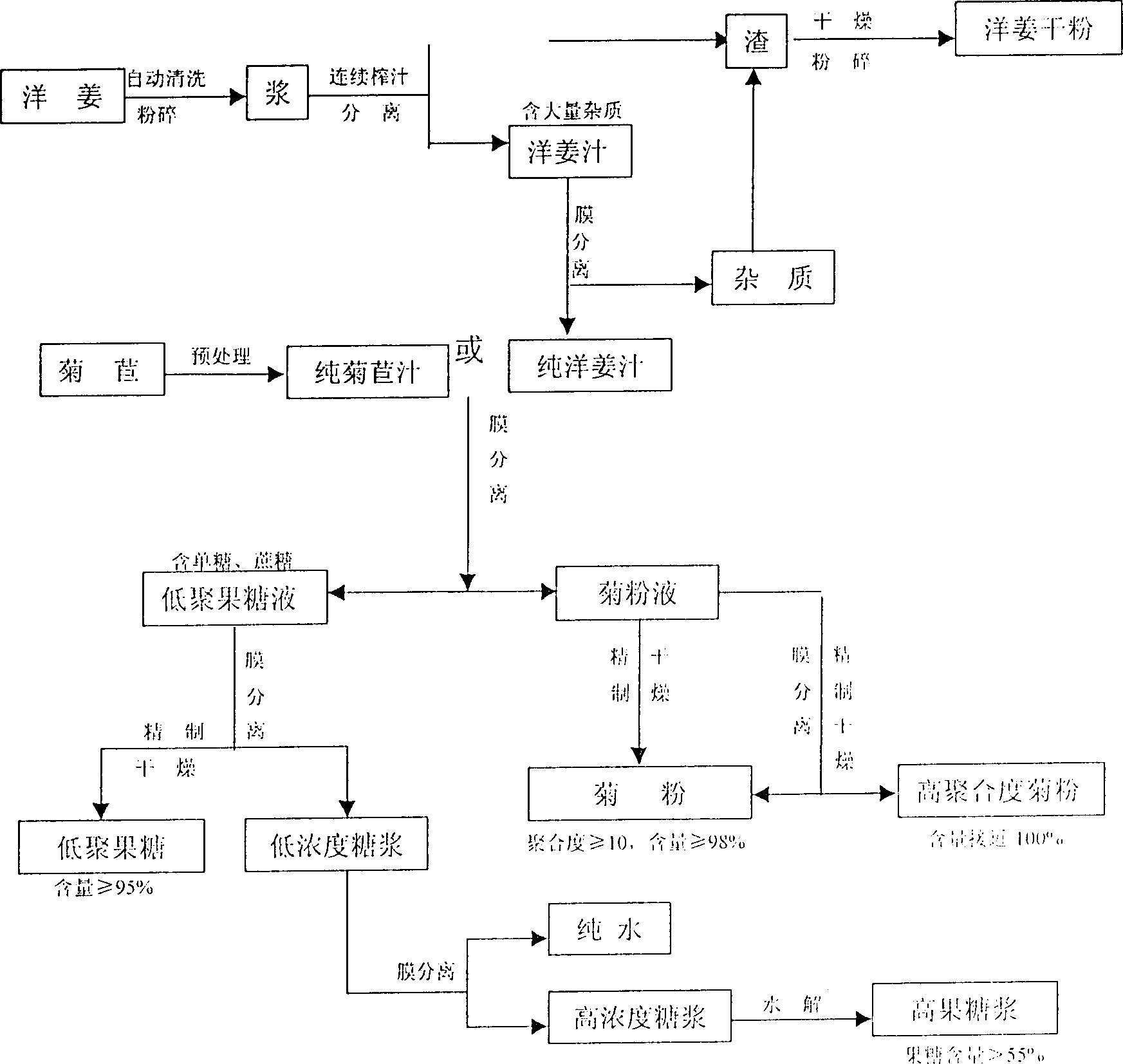

Direct membrane separating process of producing inulin and oligofructose

A fructooligosaccharide and inulin production technology, applied in chemical instruments and methods, sugar derivatives, sugar derivatives, etc., can solve the problems of no raw material source, high content of monosaccharide and sucrose, and inability to produce fructooligosaccharides in China , to achieve the effect of easy purification, high fructooligosaccharide content and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0051] Embodiment 2: take chicory as raw material.

[0052] First, it is washed and sliced according to the traditional method, and the chicory juice is extracted. Then proceed according to the processes after step 2 in the process flow of Example 1.

[0053] In sum, the present invention is not only novel, but also practical, and its described technique can be raw material production high-purity fructo-oligosaccharide and high-purity, high degree of polymerization inulin with Jerusalem artichoke, greatly simplifies the pretreatment process of Jerusalem artichoke, improves The extraction rate and utilization rate of raw materials are improved, the production process is clean, no pollutant discharge, short production cycle, high efficiency, low cost, high purity of the obtained product, low energy consumption and water consumption in the production process, easy control of the production process, etc. Advantages, and at the same time, a variety of products can be obtained ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com