Equipment for synthesizing multi-wall carbon nanotubes by water protection method

A technology of multi-walled carbon nanotubes and arc method, which is applied in the field of devices for synthesizing multi-walled carbon nanotubes, can solve problems such as poor graphitization of carbon nanotubes, affecting the quality of carbon nanotubes, and unstable arcs, etc., to achieve Simple structure, low cost, improved yield and purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

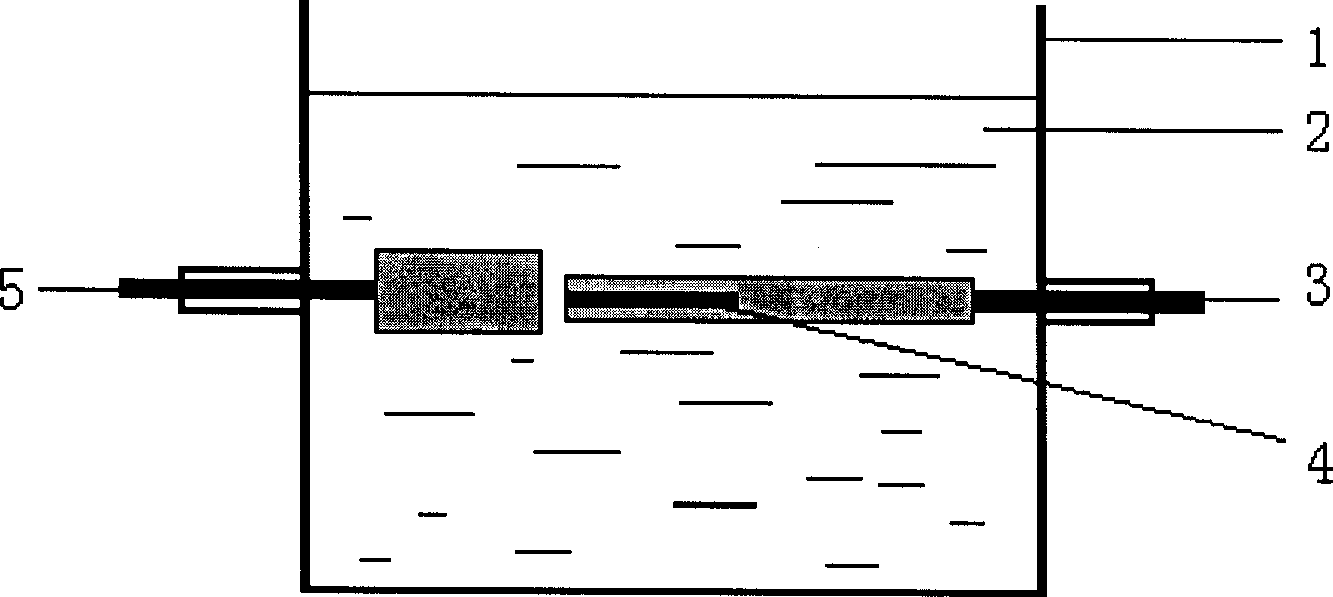

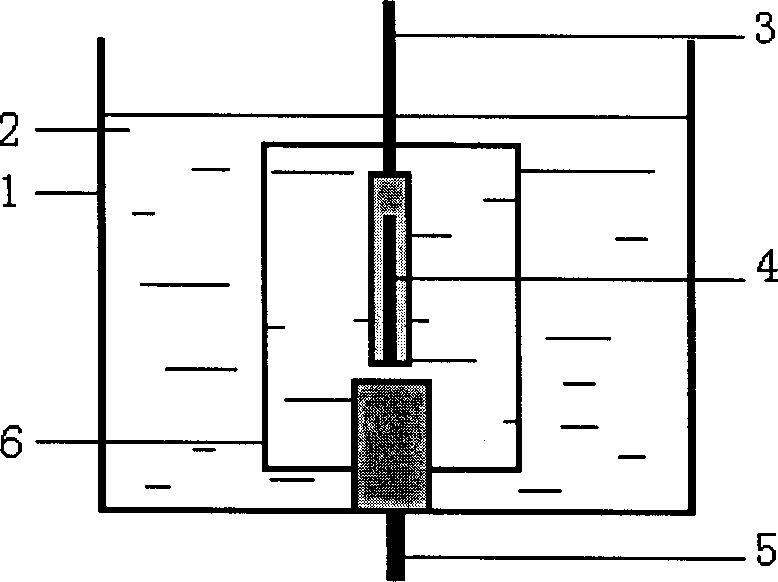

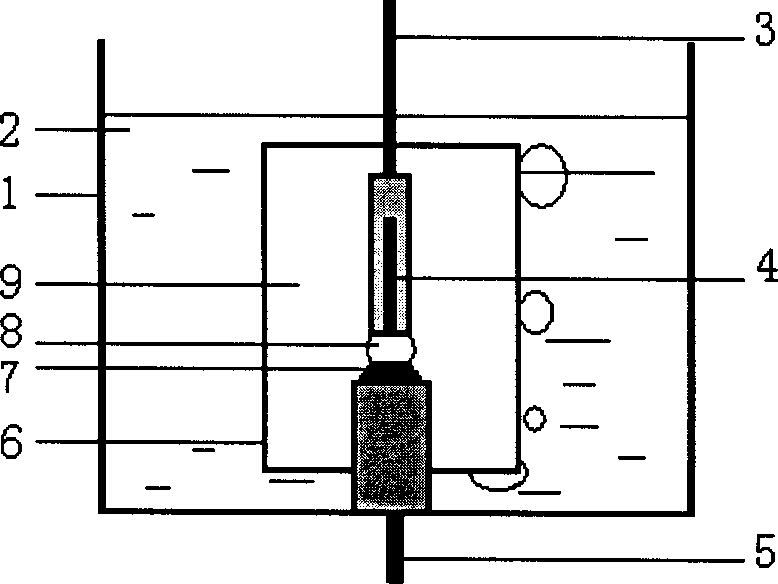

[0011] The present invention mainly comprises a water container 1, an anode rod 3 placed in water, a cathode rod 5 and a protective cover placed on the electrodes. Inside; the catalyst 4 is filled in the anode rod, the liquid in the container 1 is deionized water 2, and the cathode and anode are placed vertically, or horizontally or obliquely. like figure 2 As shown, this embodiment adopts DC welding power supply (30V, 50A), anode rod 3 is connected to the positive pole of the power supply, cathode rod 5 is connected to the negative pole of the power supply, and 1 is a plexiglass water container (long 200mm, wide 200mm, high 200mm), anode carbon The diameter of the rod is 6mm, the length is about 50mm, there are small holes drilled on it, the diameter is 3.2mm, the depth is 20-30mm, and the catalyst (Ni, Y 2 o 3 , graphite powder mixture, the atomic ratio of Ni:Y is 4.2:1, the graphite powder accounts for 95% of the total weight of the mixture), the cathode carbon rod has a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com