Method for treating food and beverage refuse into fodder and complete equipment

A technology of catering waste and treatment method, which is applied in the forming or processing of animal feed, feed, animal feed, etc., can solve the problems of inconvenient storage and transportation, waste of waste food, and large energy consumption, and achieve the elimination of odor and environmental pollution, and reduce Material and energy waste, effect of reducing floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

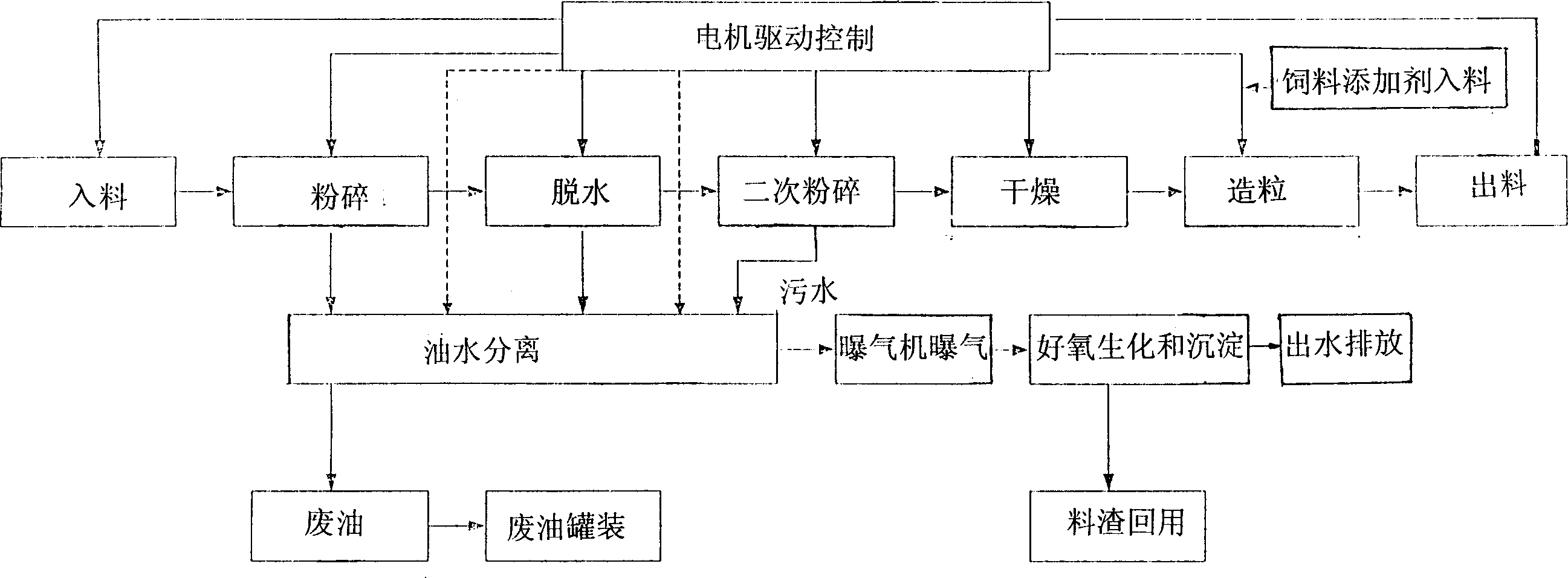

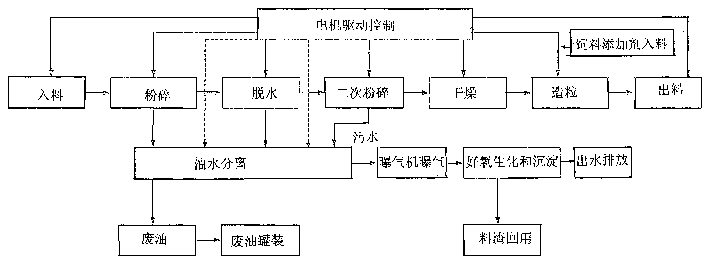

[0015] see figure 1 , the food waste feed treatment method of the present invention comprises the following steps: (1) material crushing; (2) dehydration; (3) drying; (4) granulation.

[0016] During the pelleting step, suitable feed additives may be added to the mass.

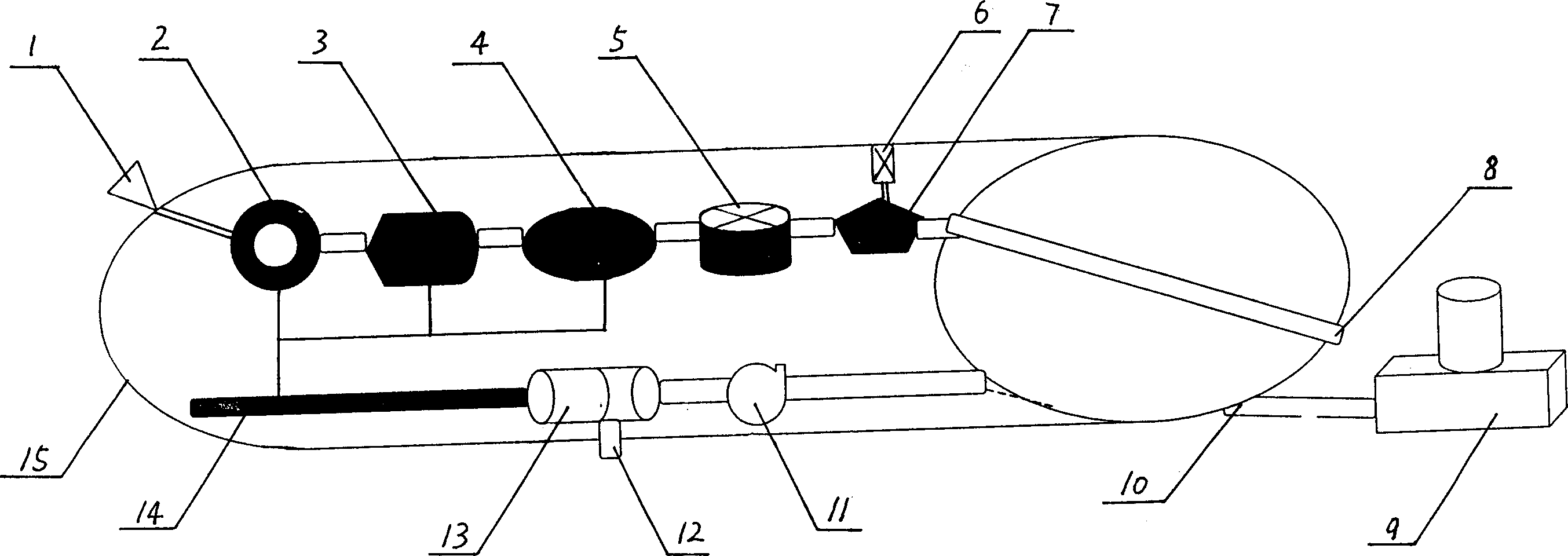

[0017] The crushing of the material can be carried out using an impact crusher, which is beneficial to the crushing of food waste; the dehydration can be carried out using a drum dehydrator, and this dehydration method is conducive to improving the dehydration effect and saving energy; the drying It can be carried out by using an electric heating dryer, which is easy to operate and can produce high-temperature conditions for inactivating microorganisms; the granulation can be carried out by using a granule mixer, and this granulation method is conducive to the mixing of materials and additives and improves the production efficiency. particle efficiency.

[0018] After the dehydration step, the dehydrated mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com