Comprehensive utilization method of converting chromium slag totally into light magnesium carbonate and fine iron breeze

A technology of light magnesium carbonate and iron concentrate powder is applied in the directions of magnesium carbonate, process efficiency improvement, solid waste removal, etc. Economic and social benefits, less corrosion of equipment, and convenient industrial implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

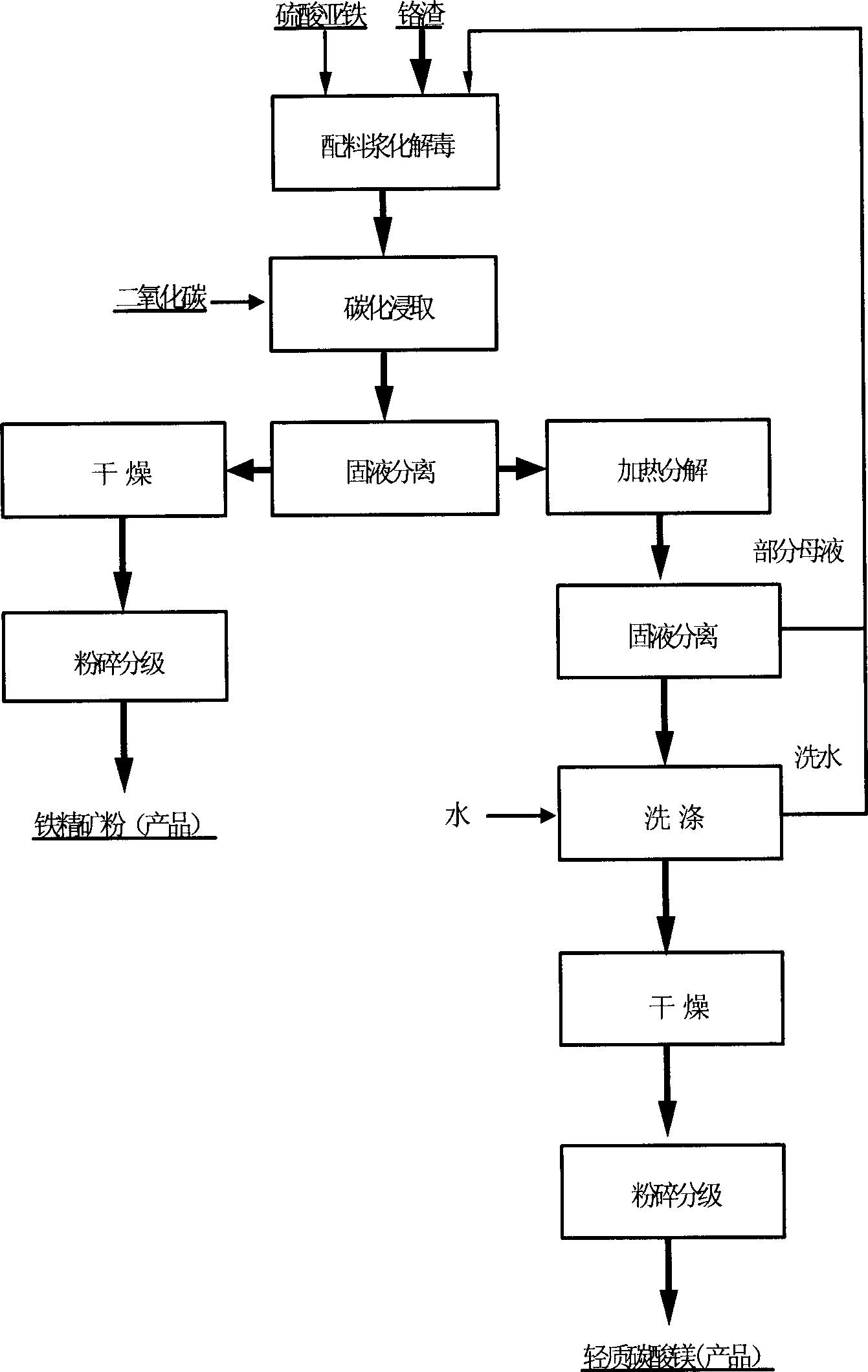

[0046] according to figure 1 The process flow is a method for preparing iron concentrate powder and light magnesium carbonate by using ferrous sulfate wet detoxification chromium slag. First take by weighing 200g of chromium slag (composition is shown in Table 1, liquid-solid ratio 1: 1) produced by Chinese patent 98100556, invention title "Clean Production Method of Sodium Chromate", 1500ml of tap water and 10g of commercially available ferrous sulfate are mixed and added Into a 2L autoclave, heat up to 40°C and feed CO 2 to CO 2 Partial pressure is 5Kg / cm 2 , stirred and reacted at a speed of 150 rpm for 1 hour, vacuum filtered the reacted slurry to obtain iron concentrate filter cake and heavy magnesium water. The iron concentrate filter cake was dried at 120°C for 1 hour to obtain 75g of iron concentrate, of which Fe 2 o 3 The MgO content is 54.3%, and the MgO content is 3.6%. The composition is shown in Table 2. Heavy magnesium water is heated to 100°C to decompose,...

Embodiment 2

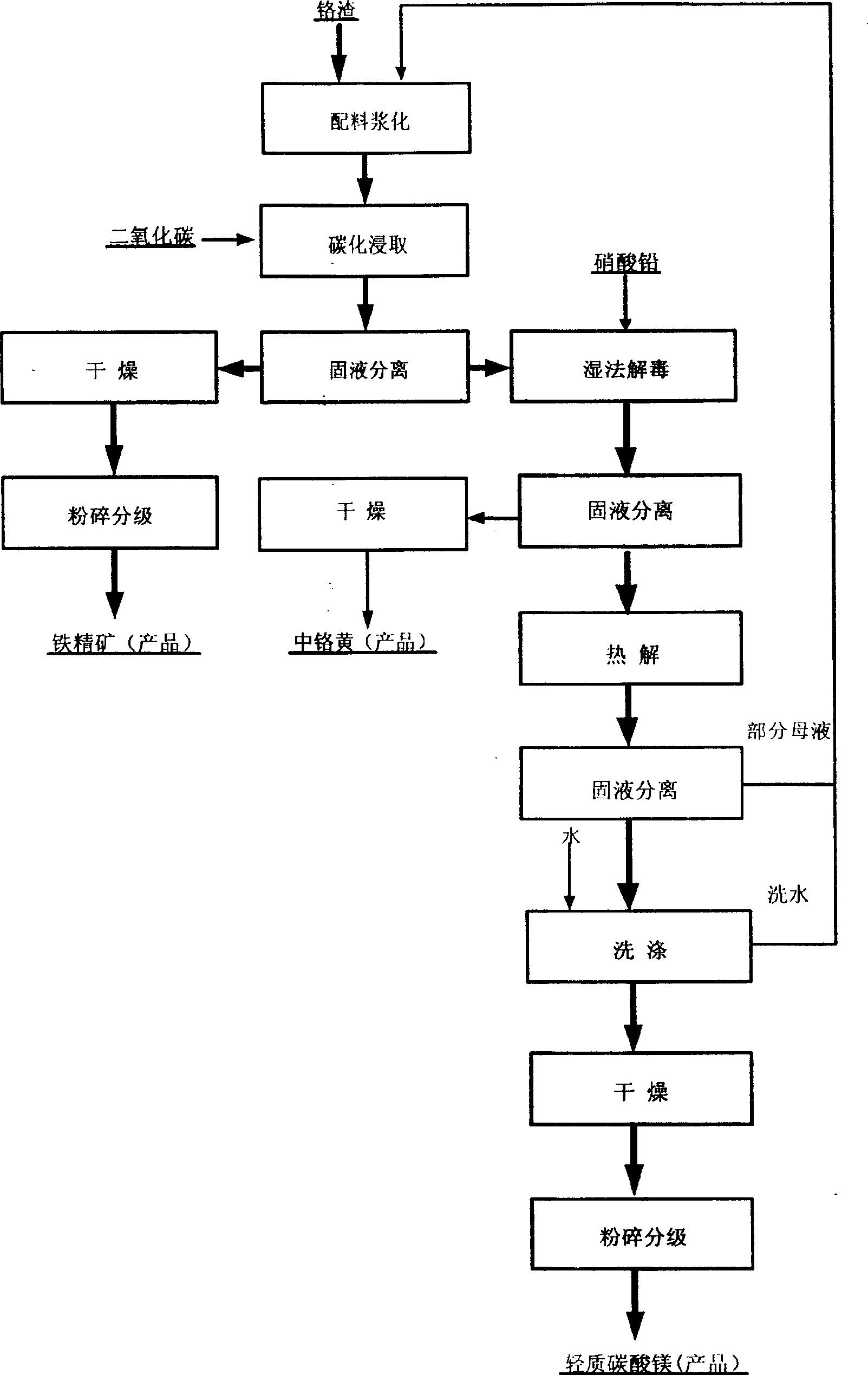

[0051] according to figure 2 The process flow shown is a method for preparing iron ore concentrate powder and light magnesium carbonate by wet detoxification of chromium slag with lead nitrate. First, take 200g of chromium slag (composition is shown in Table 1, liquid-solid ratio 1:1) produced by Chinese patent 98100556, invention title "Clean Production Method of Sodium Chromate", add 1500ml of tap water to a 2L autoclave after mixing , heated up to 40°C, and CO 2 to CO 2 Partial pressure is 5Kg / cm 2 , stirred and reacted at a speed of 150rpm for 1 hour, vacuum filtered the reacted slurry to obtain iron concentrate filter cake and heavy magnesium water; iron concentrate filter cake was dried at 120°C for 1 hour to obtain 70g of iron concentrate , where Fe 2 o 3 The content is 51.2%, and the MgO content is 3.8%; then weigh 5gPb(NO 3 ) 2 Dubbed into 100ml aqueous solution, Pb(NO 3 ) 2 The solution was added to the above heavy magnesium water, stirred and reacted at a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com