High-frequency and high-pressure oil and water separating method and devices

A high-frequency, high-pressure, oil-water separation technology, which is applied in the direction of electric liquid separation, can solve the problems of reduced efficiency, unsatisfactory production, and increased difficulty of electric dehydration, so as to suppress continuous arc generation, increase speed, and avoid catalyst poisoning. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

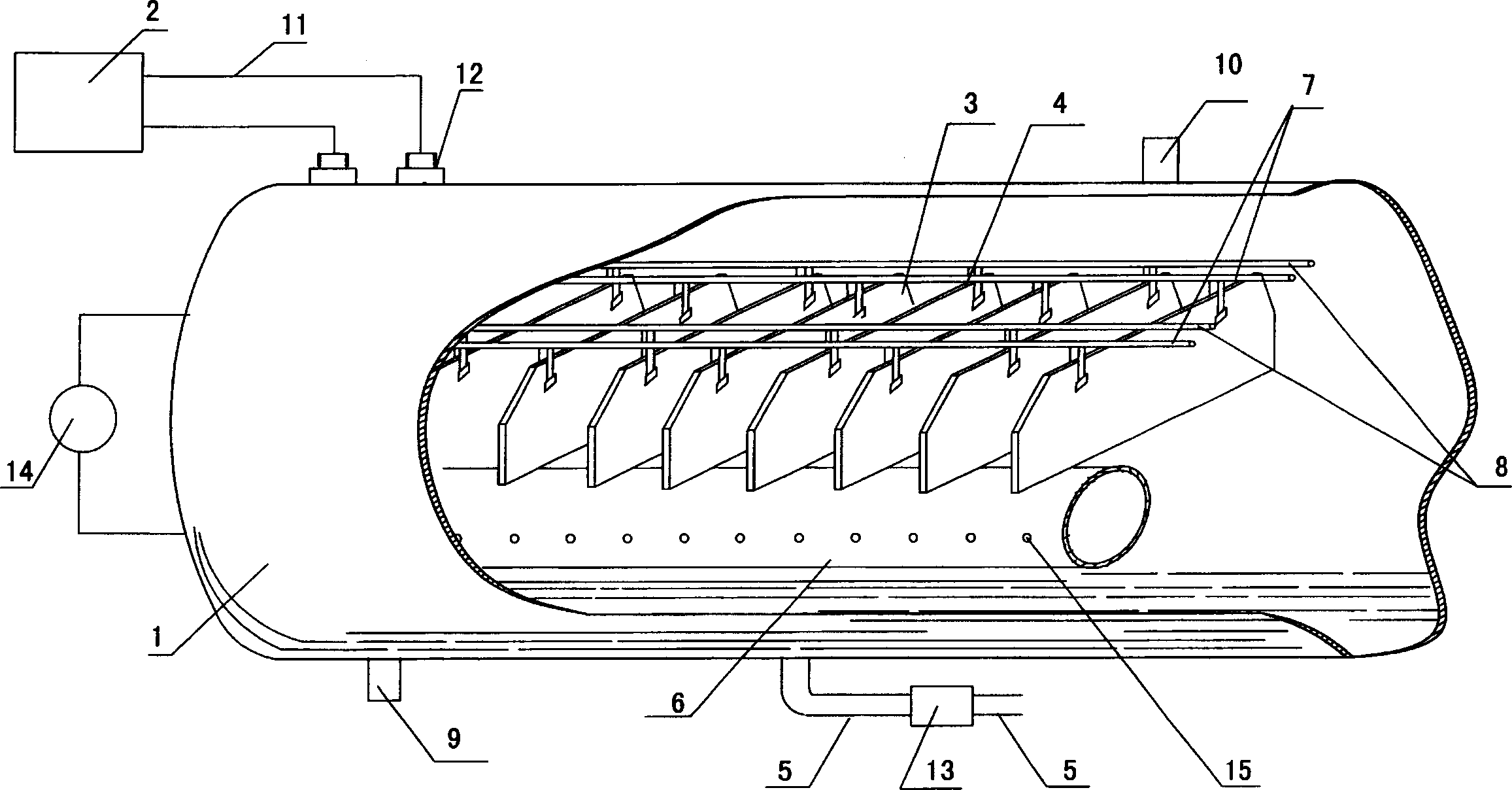

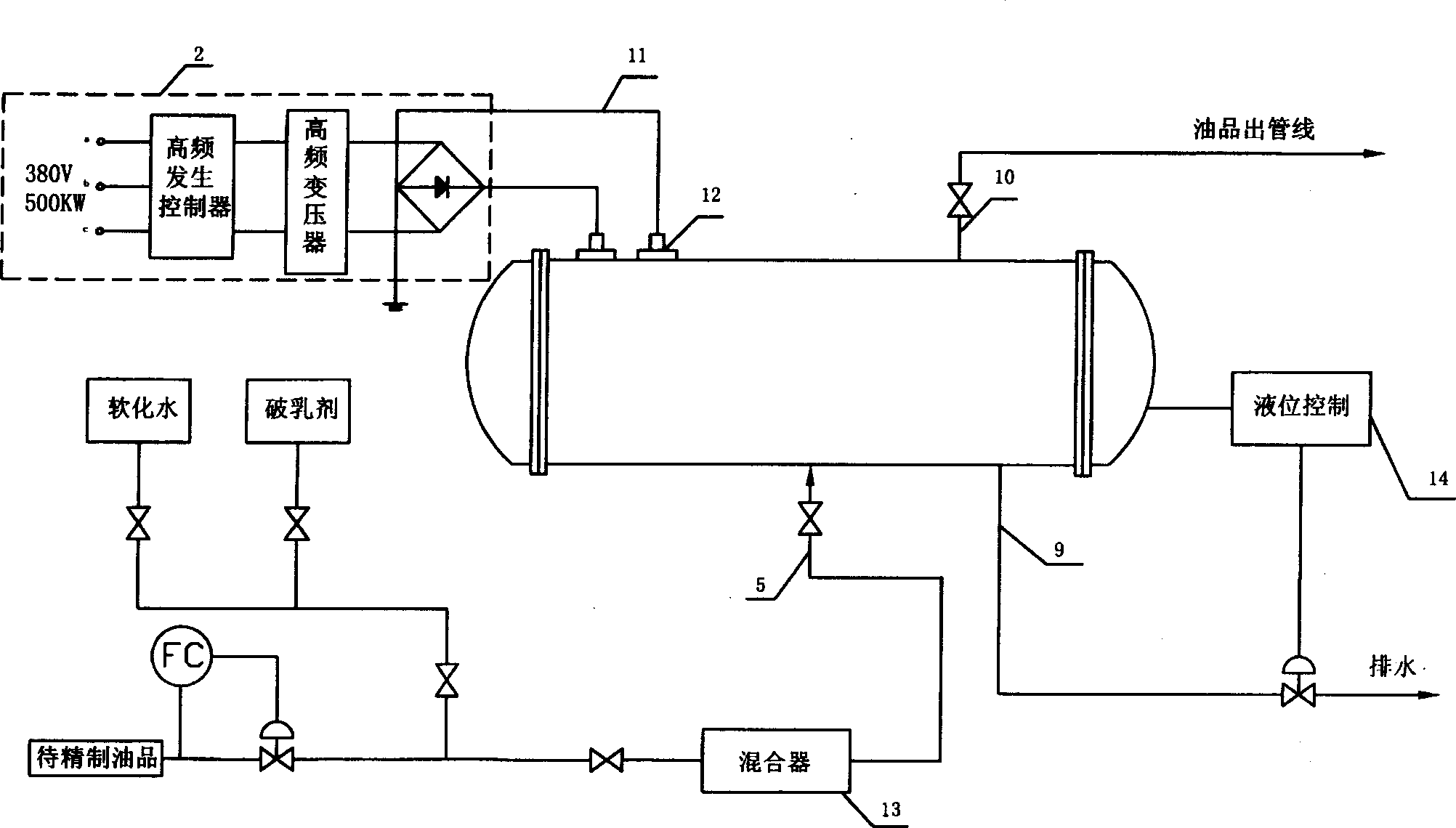

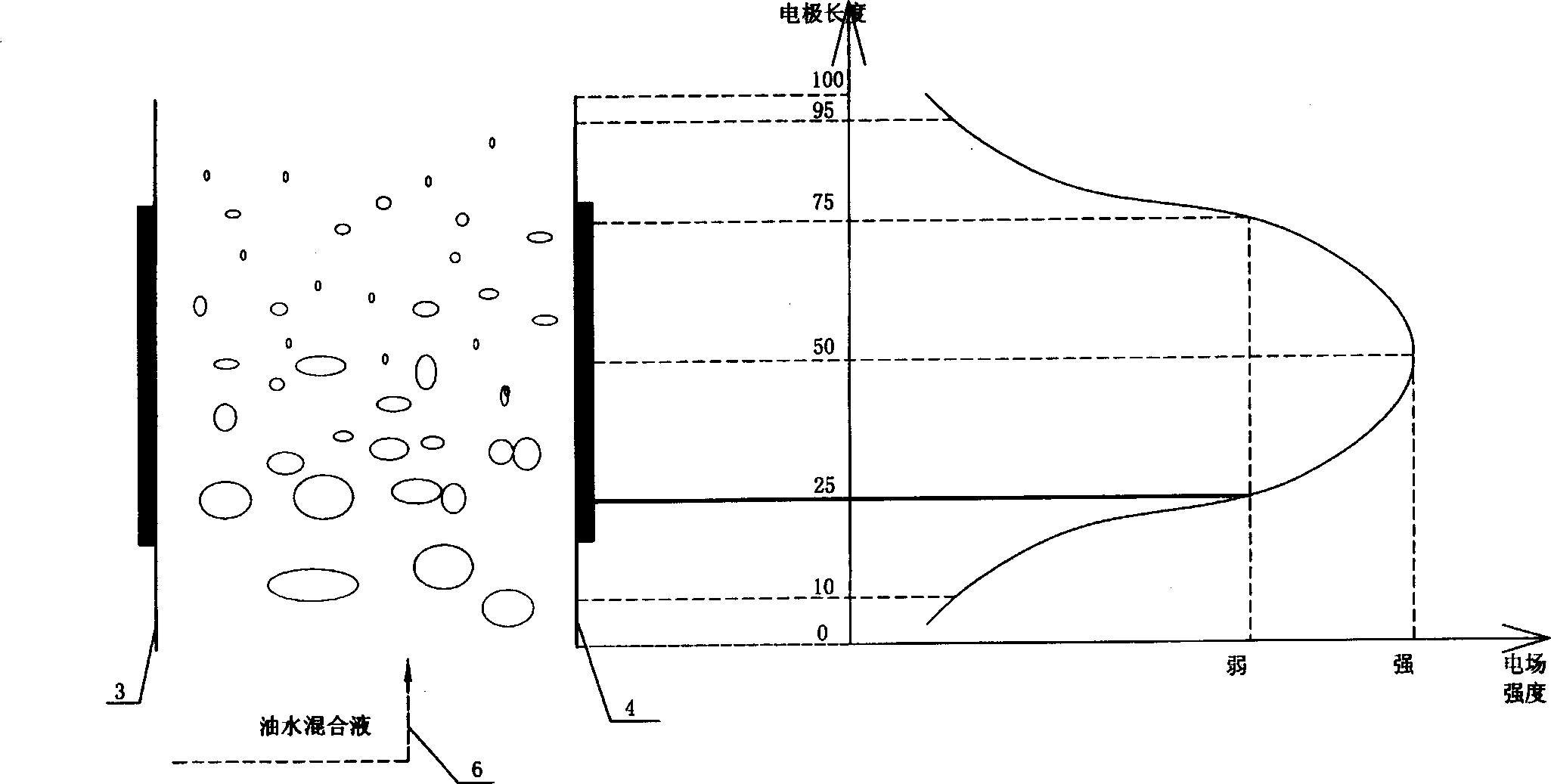

[0027] See figure 1 As shown, a high-frequency and high-pressure oil-water separation device of the present invention includes a power supply device, a mixing device, and a separation device. The separation device is an oil-water separation tank, which consists of a tank body 1 and a high-pressure introduction rod 12 arranged on the outside of the tank body 1, an oil outlet pipe 10, a water outlet pipe 9, an oil inlet pipe 5, a liquid level controller 14, and a tank body 1. The inner oil distribution pipe 6, the positive electrode plate 3, the negative electrode plate 4, the positive pole suspension beam 7, and the negative pole suspension beam 8 are formed. The two ends of the two electrode suspension beams are wrapped and fixed on the left and right ends of the tank body 1 by polytetrafluoroethylene or polyester plus glass fiber. The oil-water separa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com