Method of producing ethyl acetate and equipment for carrying out this method

A technology of ethyl acetate, acetic acid, applied in the field of production of ethyl acetate and the equipment for implementing it, capable of solving the problems of unfavorable, high hydrodynamic resistance, corrosive environment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

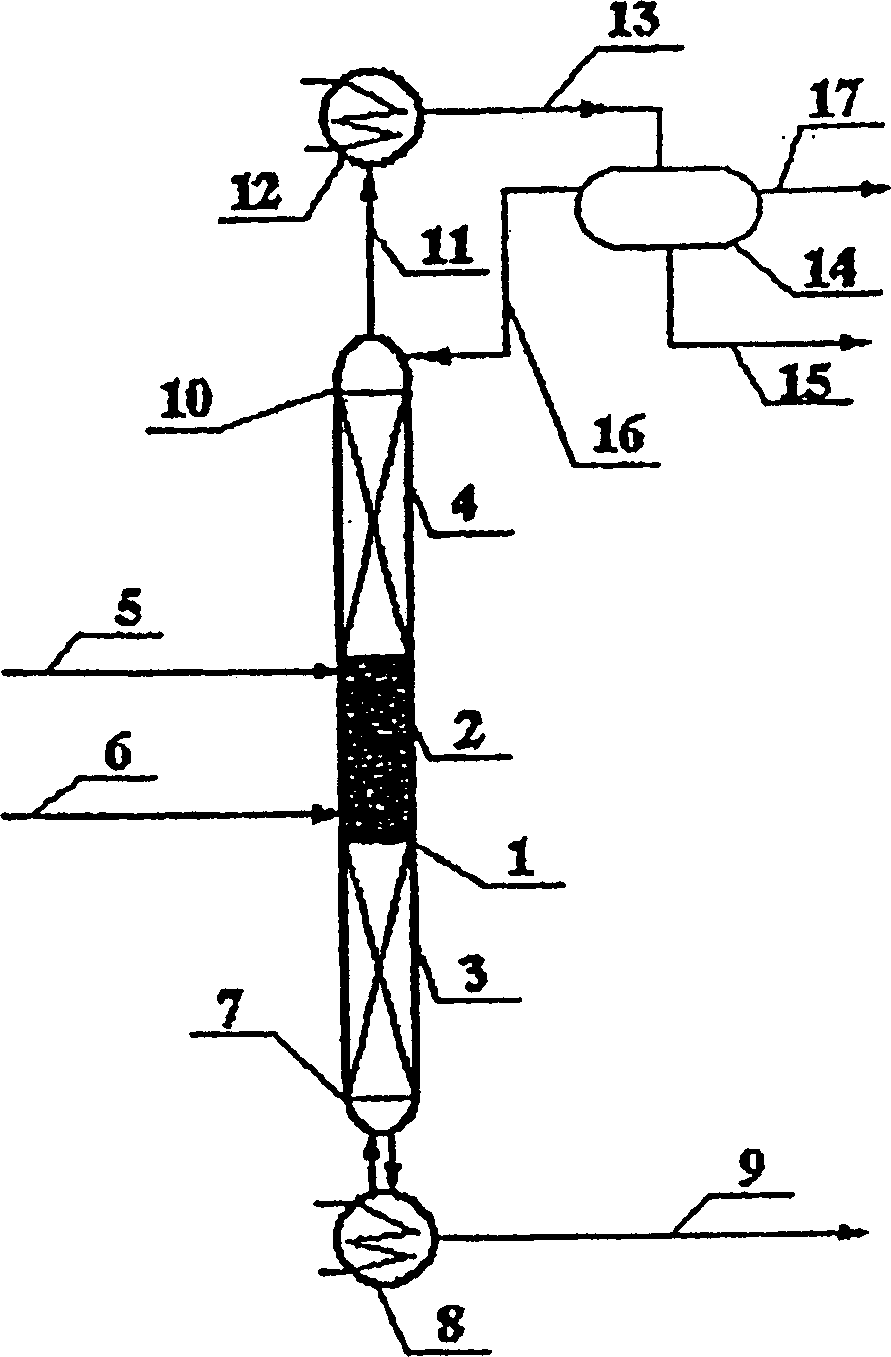

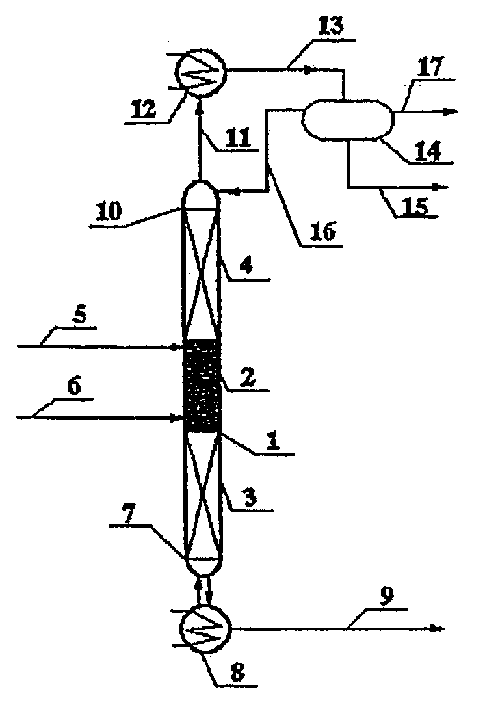

[0017] figure 1 A schematic representation of the apparatus of the present invention is shown. Catalytic distillation column operated continuously at atmospheric pressure 1 Divided into 3 zones. tower 1 The reaction zone is formed in the middle of 2 . in the reaction zone 2 Below is the bottom separation area 3 , in the reaction zone 2 Above is the upper separation zone 4 . Boiler 8 with tower bottom 7 connected. condenser 12 with the top of the tower 10 connected. Splitter 14 with condenser 12 connected.

[0018] reaction zone 2 The medium is packed with a catalytically active packing containing 33 g of acetic acid ion exchanger. Pouring fill is filled in the bottom separation area 3 and upper separation area 4 Medium (arc saddle packing with a diameter of 4mm). Separation zone 3 with 4 The length is 0.5m.

[0019] The production method is that the ethanol feed is passed through the pipeline 6 into the bottom separation zone 3 , acetic acid feed...

Embodiment 2

[0020] Except that acetic anhydride is used as the raw material instead of acetic acid, ethyl acetate is synthesized under the same conditions as in Example 1, and the acetic anhydride reacts with ethanol in an equimolar ratio to generate acetic acid and ethyl acetate in a prereactor. The reaction mixture is then added to the column 1 in place of acetic acid. The selected total molar ratio of ethanol to acetic anhydride was 1.52. Using a reflux ratio of 1:6, the unit delivered 0.46 mol / h of crude ethyl acetate with a purity of 91.4% by weight. Apart from ethyl acetate, the product contained only 5.2% by weight of water and 3.4% by weight of ethanol. Splitter 14 The output of the separated aqueous phase was 3.9 ml / hour. Example 3

Embodiment 3

[0021] with including a boiler with a volume of 50 liters 8 , equipped with a condenser 12 and separator 14 the tower 1 The apparatus implements the esterification of ethanol by acetic acid. catalytic distillation column 1 including reaction zone 2 , the reaction zone 2 Catalytically active packing KATAPAK S, the packing has 1.07kg H + form of acidic ion exchangers. bottom separation zone 3 and upper separation zone 4 The directional packing (bottom separation zone) with an effective rate of 12 is filled in the medium, that is, 20 theoretical plates. Acetic acid is passed through the pipeline at an amount of 0.73kg / hour 5 into the reaction zone 2 , passing ethanol through the pipeline at an amount of 0.41kg / hour 6 Conveying into the bottom separation area 3 upper boundary of . The water produced by this reaction is removed from the separator 14 through the pipeline 15 Drain, pass the organic phase through the tube 16 reflux into tower 1 , a portion of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com