Laser multiple degree-of-freedom measuring system and method

A technology of measurement system and degree of freedom, applied in the field of laser precision measurement system, can solve problems such as difficult to achieve fast and convenient measurement, inconvenient on-site measurement, complex optical system, etc., to achieve convenient measurement, simple structure, and simple optical path adjustment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

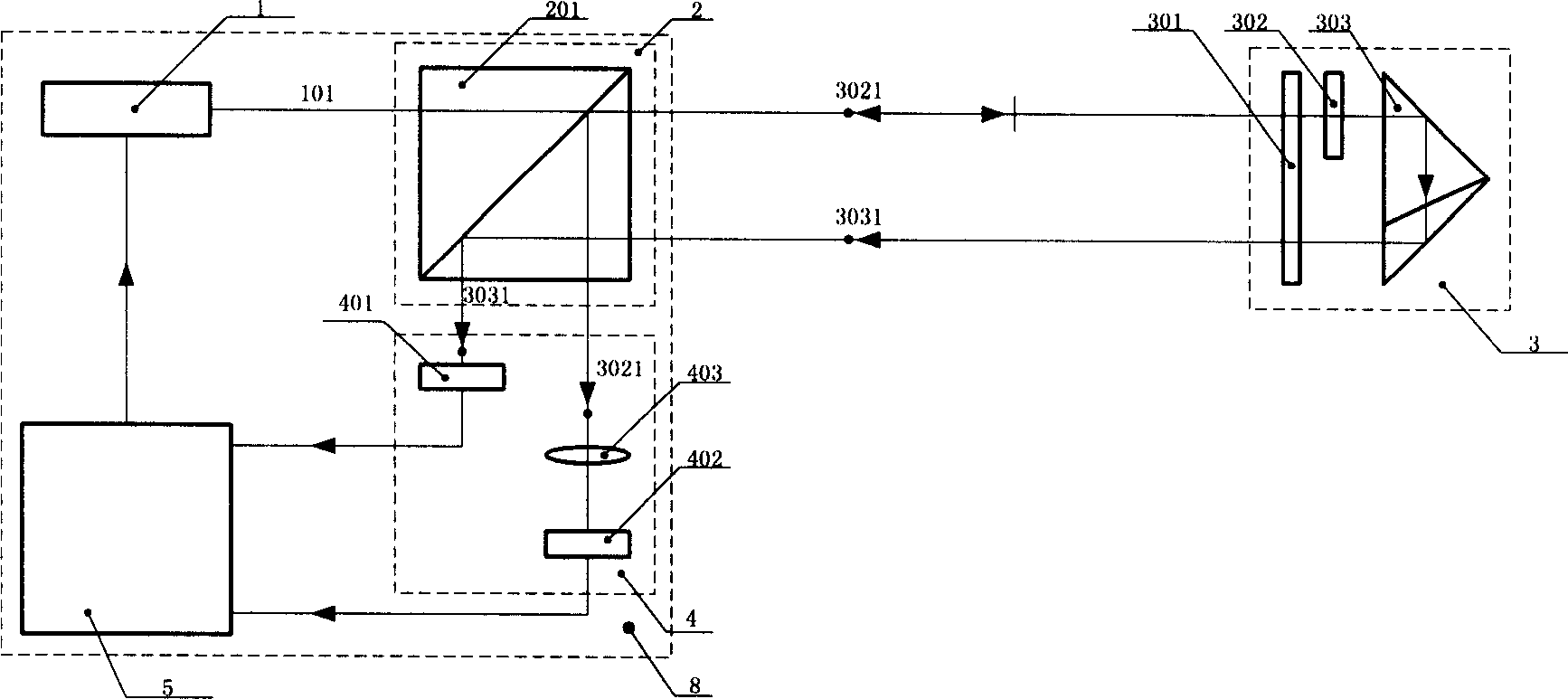

[0034] Implementation mode one ( figure 1 ):

[0035] The four-degree-of-freedom error sensitive unit 3 in the system is composed of a λ / 4 wave plate 301 , a beam splitter 302 and a light reflector 303 . The λ / 4 wave plate 301, the beam splitter 302 and the light reflector 303 are arranged along the direction of the incident light, and are fixed together by brackets or other means; the said λ / 4 wave plate 301 changes linearly polarized light into circularly polarized light, Or change circularly polarized light into linearly polarized light, said beam splitter 302 divides one beam of incident light into at least two beams of light, one beam is reflected, and the other beam is transmitted, and said light reflector 303 reflects the incident light back , but not coincident with the original incident light. The beam splitter 302 is fixed on the incident light path of the light reflector 303, and the light 3031 reflected by the light reflector 303 of the incident light no longer p...

Embodiment approach 2

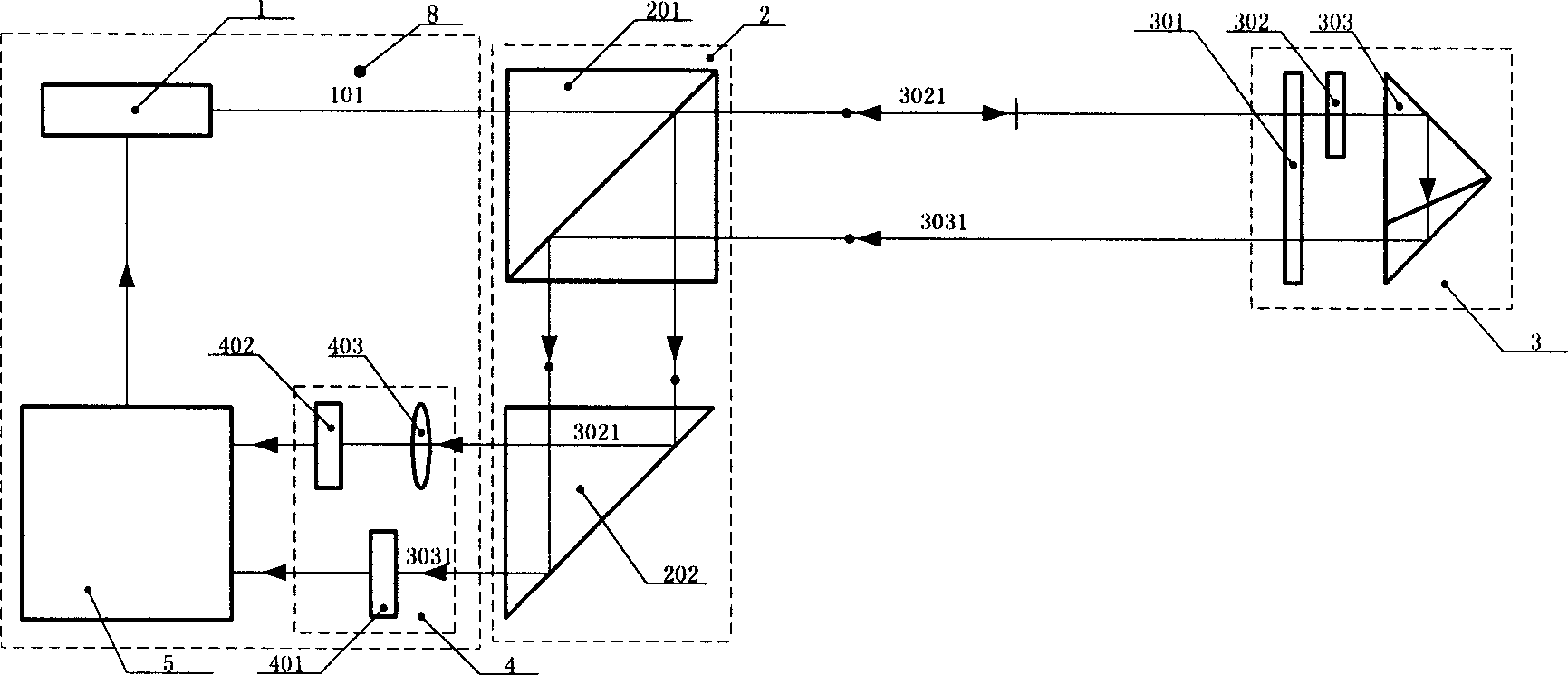

[0036] Implementation mode two ( figure 2 ):

[0037] The difference from Embodiment 1 lies in: the polarizing beam splitting unit 2 , which is composed of a polarizing beam splitter 201 and a total reflector 202 . The total reflector 202 and the polarizing beam splitter 201 can be connected separately or directly connected together. At the same time, the total reflector 202 can be a right-angle reflective prism or a plane mirror; the polarizing beam splitter unit 2 can be connected together with the fixed measuring head 8 of the measuring system, and can also be connected separately.

Embodiment approach 3

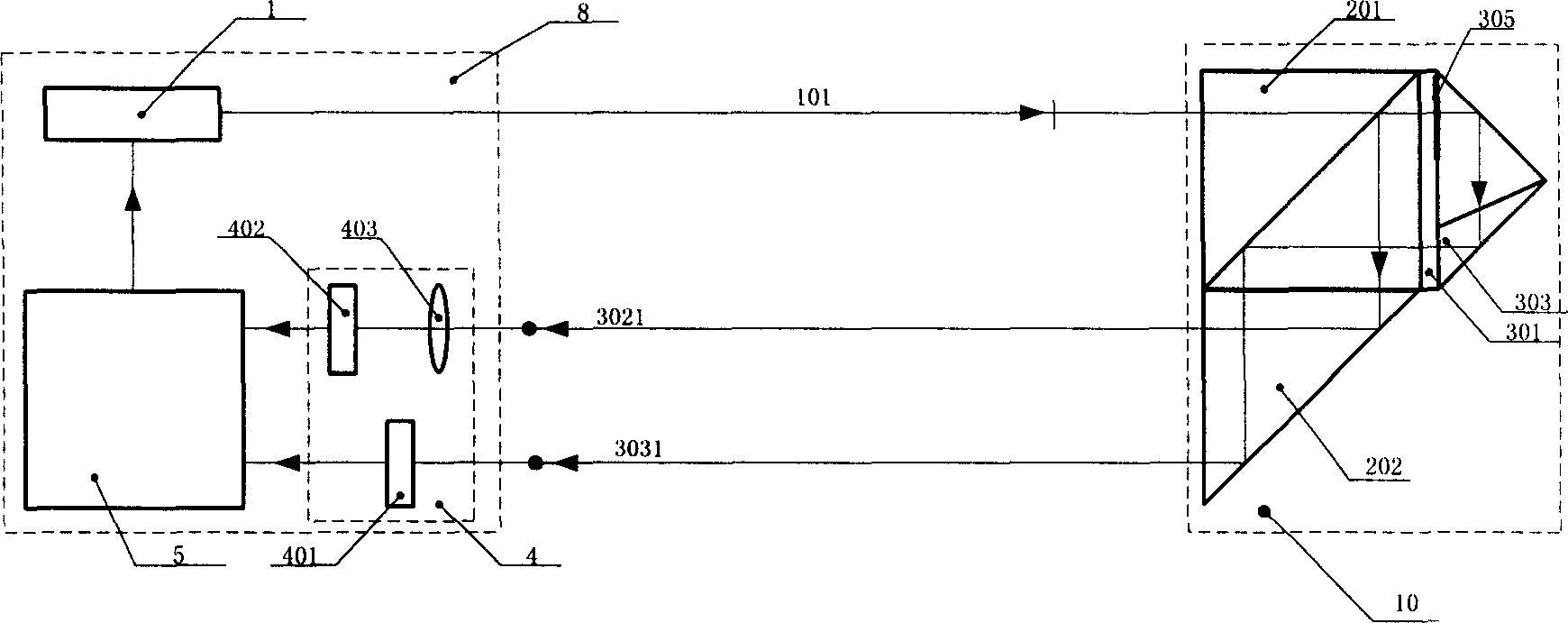

[0038] Implementation mode three ( image 3 ):

[0039] The difference from Embodiment 1 and Embodiment 2 is that in the four-degree-of-freedom error-sensitive unit 3, the light-splitting film 305 is directly coated on the incident side or the outgoing light side of the light reflector 303, and the light-splitter is removed. 302. At the same time, the polarization beam splitting unit 2 and the four-degree-of-freedom error sensitive unit 3 are directly connected together to form the movable measuring head 10 of the measuring system. On the fixed measuring head 8 of the measuring device, only the laser transmitter 1 , the photoelectric receiving unit 4 and the signal processing unit 5 are installed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com