Liquid cooling LED packaging method

A technology of light-emitting diodes and laser diodes, applied in electrical components, electric solid-state devices, circuits, etc., can solve the problems of high unit price, difficult heat conduction, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

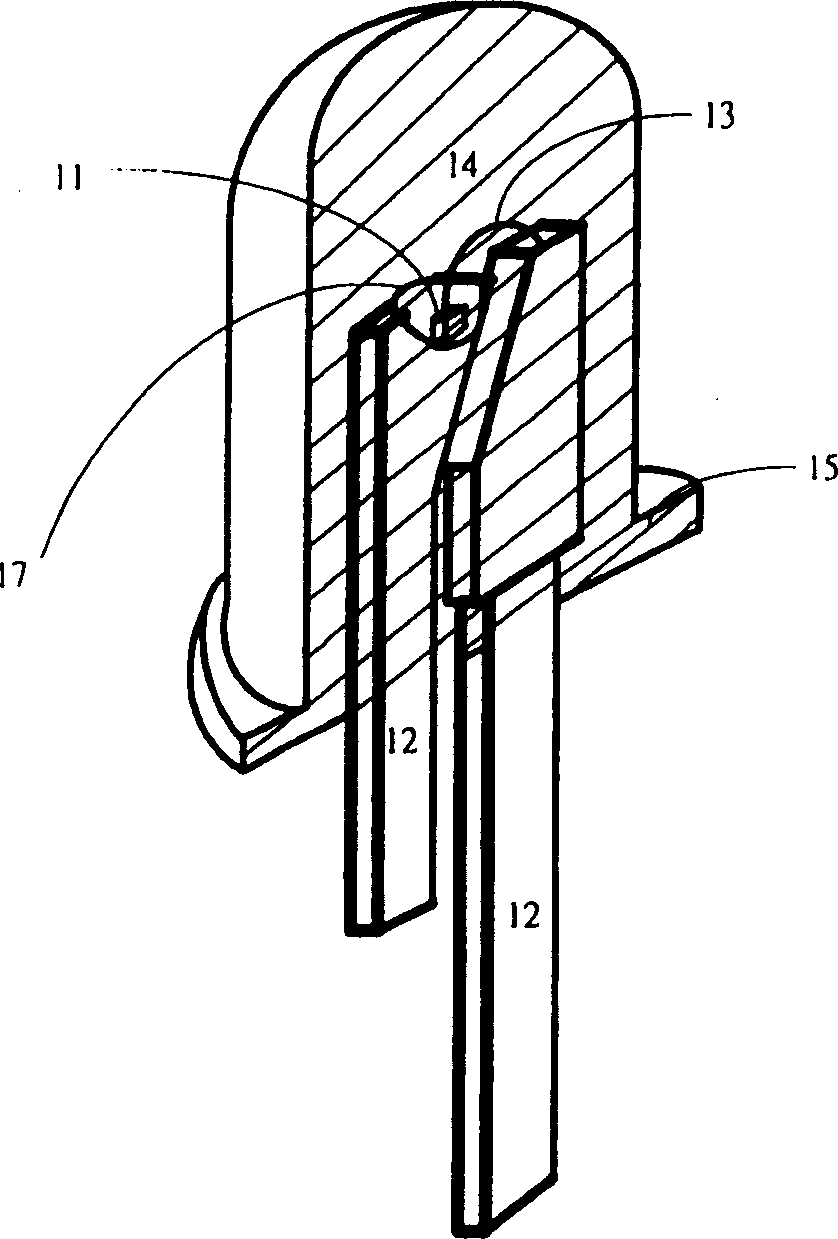

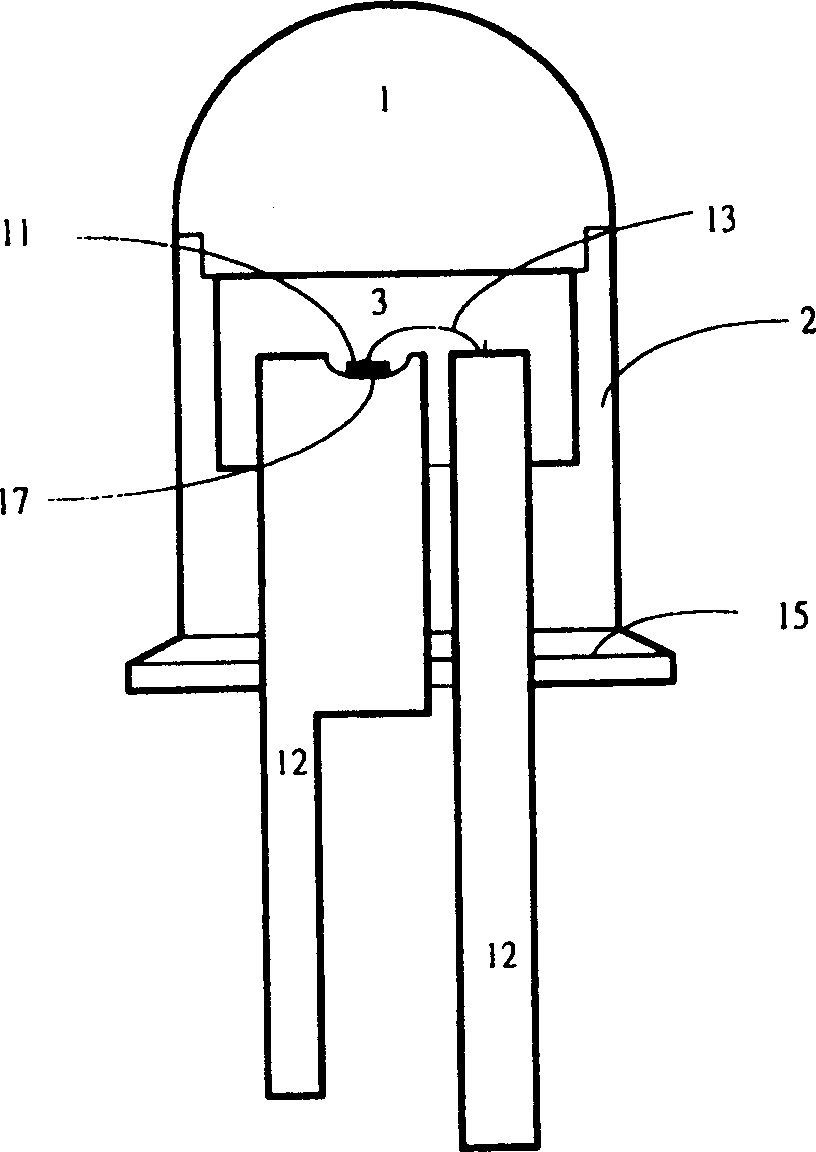

[0107] Embodiment 1 (liquid-cooled light-emitting diode)

[0108] refer to Figure 4 The light-emitting diode crystal grain 11 is fixed on the grain receiving seat 17 at the center of the base 15 with conductive thermal colloid, and then the positive and negative electrode pads on the surface of the crystal grain 11 and the conductive support frame 12 are respectively connected with gold wires or aluminum wires 13 The top of the LED, so that the light-emitting diode crystal grain 11 can be connected to the external circuit (not shown) through the conductive support frame 12, but if the crystal grain is the bottom of the aluminum indium gallium phosphide (AlInGaP) type, it needs to be additionally applied such as a silicon chip. or AlN or BeO or sapphire (Al 2 o 3 ) and other high thermal conductivity insulating devices 9 (sub-mount), there is a metal layer on the surface of the crystal as the second contact point of the crystal grain, and the metal layer is connected to anot...

Embodiment 2

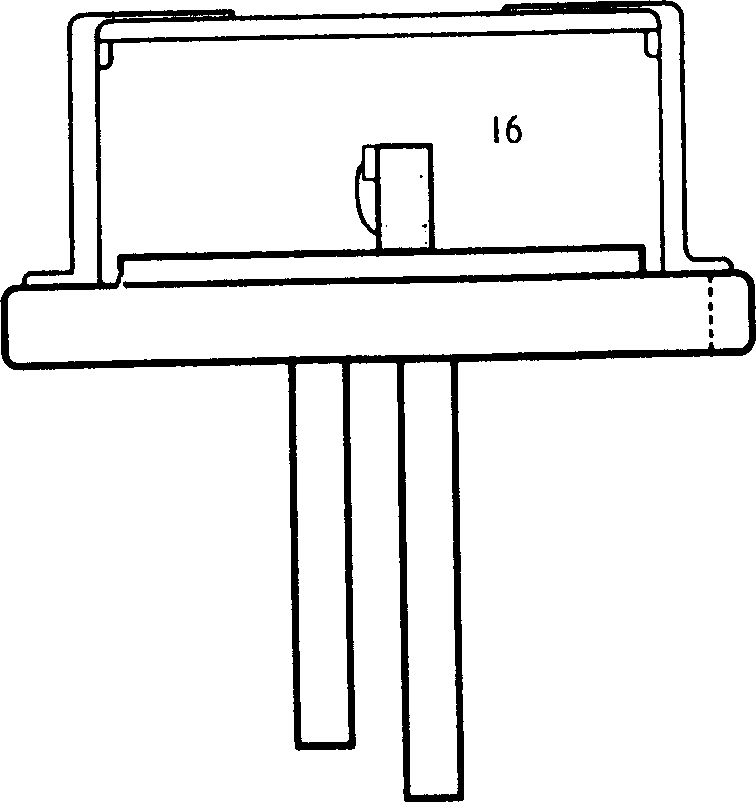

[0110] Embodiment 2 (package combination example of high-power liquid-cooled light-emitting diode)

[0111] refer to Figure 5 , illustrating the package combination example of the high-power liquid-cooled light-emitting diode related to the present invention. Figure 5 It is a package combination diagram of the high-power liquid-cooled light-emitting diode related to the present invention, three of which are lens dome 1, lamp holder 20 (the wall and the additional heat sink 18 are integrally formed), and base 15 The assembly steps are as follows:

[0112] First, the crystal grains are fixed on the base 15 and wires are bonded. The crystal grains 11 are fixed on the base 15 with conductive thermal colloid (not shown in FIG. The top of the negative electrode pad and the conductive support frame 12 makes the crystal grain be connected with the external circuit (not shown in the figure) via the conductive support frame 12 Figure 5 ), but the conductive support frame 12 and th...

Embodiment 3

[0113] Embodiment 3 (Single liquid-cooled LED light source formed by substrate chip bonding technology (COB), strip liquid-cooled LED light source module formed by substrate chip bonding technology (COB), substrate chip bonding technology (COB) Formed planar liquid-cooled light-emitting diode light source module)

[0114] refer to Figure 6 , illustrating an example of package combination of a single liquid-cooled light-emitting diode light source formed by chip-on-board (COB) bonding technology related to the present invention. Figure 6 A single liquid-cooled light-emitting diode is similar to the high-power liquid-cooled light-emitting diode of embodiment 2, only the light-emitting diode base 15 is changed to a PCB board 24, and a single COB liquid-cooled light-emitting diode ( Figure 6 ) can be regarded as another packaging combination example of high-power liquid-cooled light-emitting diodes. The usage is the same as that of traditional surface mount components (SMTdevi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| impedance | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com