IGCC power station coupling liquefaction air separation equipment system and working method thereof

An air separation plant and power station technology, applied in liquefaction, gasification process, mechanical equipment, etc., can solve the problem that IGCC generator sets cannot respond to grid peak regulation and frequency regulation auxiliary services, and the depth and response rate of peak regulation cannot meet grid requirements and respond. The speed and frequency modulation depth are limited and other problems, so as to increase the output, meet the peak and frequency modulation load requirements, and improve the efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

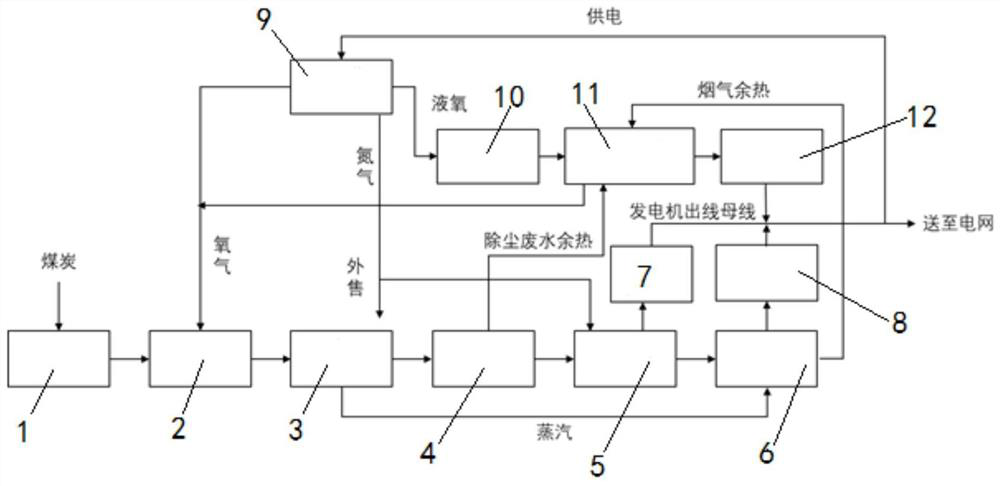

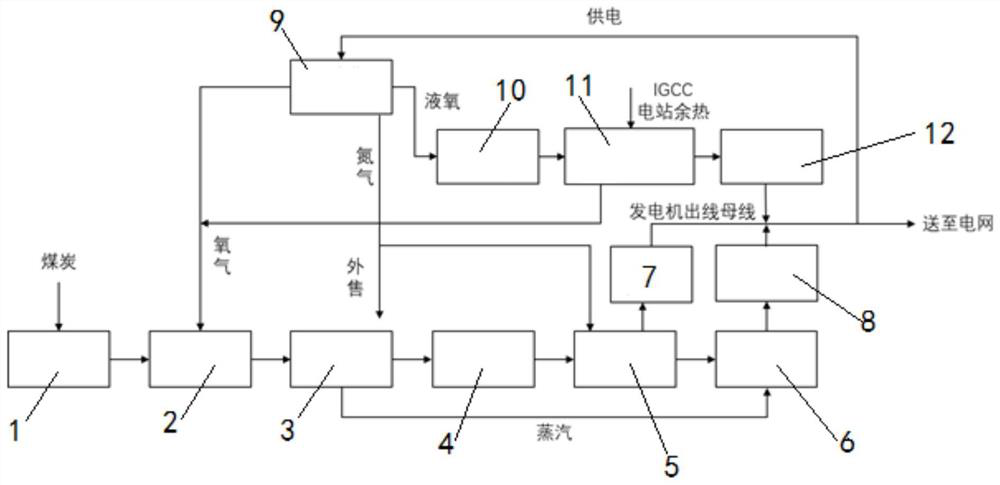

[0038] Such asfigure 1 As shown, the present invention provides an IGCC power station coupled liquefaction air separation equipment system, including a gasifier 2, a waste heat boiler 3, a dust removal and desulfurization purification unit 4, a gas turbine 5 and a waste heat boiler 6 connected in sequence, and coal passes through a coal pretreatment unit 1 Enter the gasification furnace 2 for combustion, after dust removal and desulfurization, connect the gas generator 7 to the gas turbine and the steam generator 8 to the waste heat boiler 6, and the electric energy output of the gas generator 7 and steam generator 8 is connected to the power grid , the power grid also supplies power to the liquefied air separation unit 9, which is a device that adopts a cryogenic liquefaction method to separate air components, and the oxygen outlet of the lique...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com