Fine preparation process for high-purity nitrogen trifluoride gas

A refining method, nitrogen trifluoride technology, applied in the direction of fluoride preparation, nitrogen and non-metallic compounds, electrolytic components, etc., can solve the high difficulty of gas impurities, equipment processing, process realization difficulty and high refining cost, unfavorable gas industrialization Production and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The following is a detailed description of a specific embodiment of the present invention.

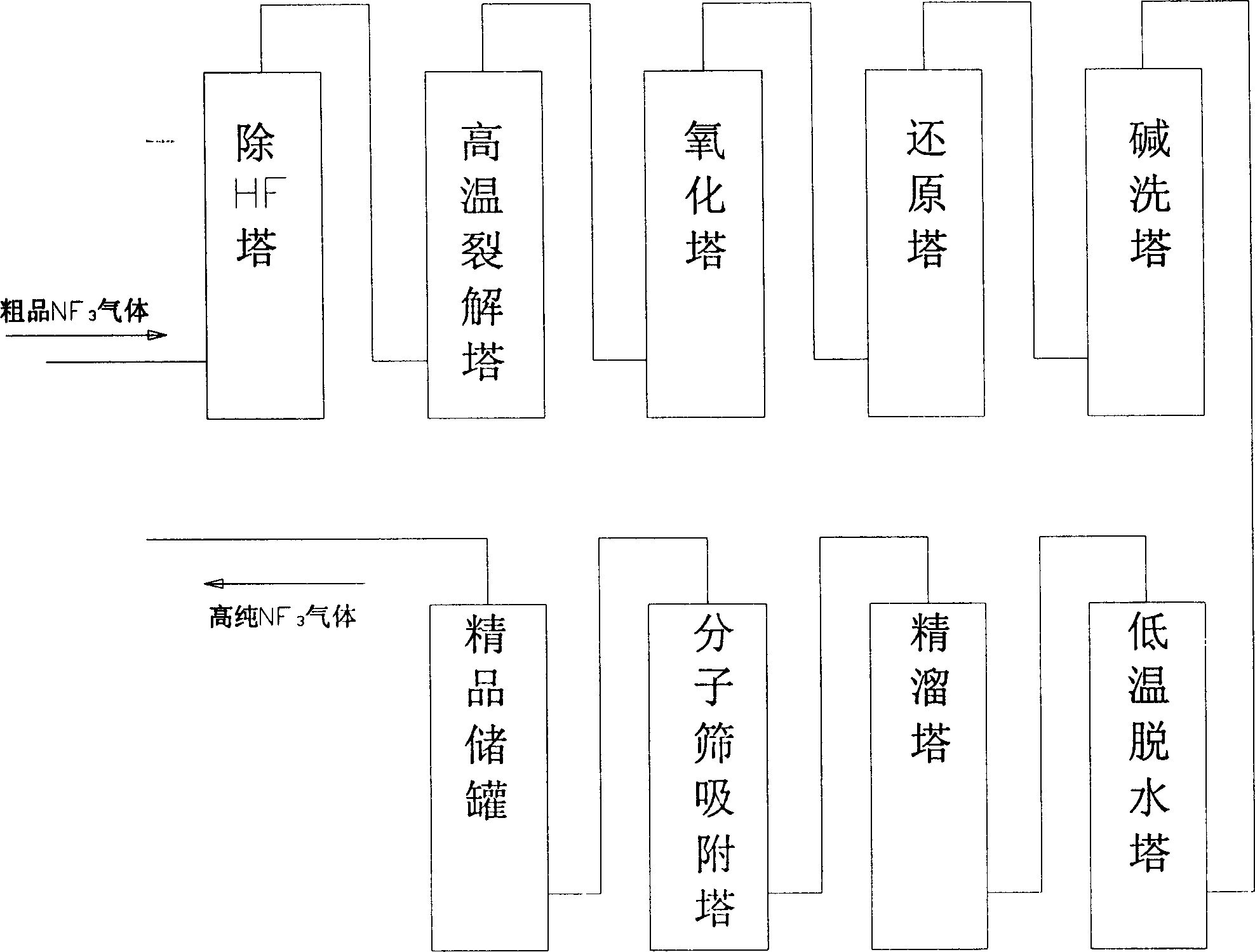

[0040] Process method of the present invention is:

[0041] The first step is to remove H in the feed gas in the HF removal tower 2 O, HF and other impurities. Feed gas adopts 97% crude product NF shown in Table 1 3 Gas, the temperature of the HF removal tower is controlled at -90°C, the pressure is 0.4MPa, and the residence time of the raw material gas in the tower is 20 minutes.

[0042] components

[0043] The second step is to remove N in the feed gas in the pyrolysis tower x f y , F x o y . The high-temperature cracking tower is filled with NaF sheets, and the internal temperature is controlled at 200°C, the pressure is controlled at 0.39MPa, and the residence time of the raw material gas in the tower is 20 minutes.

[0044] The third step is to remove N in the raw gas in the oxidation tower 2 O impurity. Oxidation tower filled with Na 2 o 2 , the temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com