Process and apparatus for synthesis of gas

A synthesis process and gas technology, applied in the direction of fuel, petroleum industry, gas fuel, etc., can solve the problems that affect the operation efficiency and promotion of gas boilers, the complex manufacturing process of the combustion system, human and animal poisoning and suffocation, etc., to save one time High effective utilization rate of energy and heat, good environmental protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

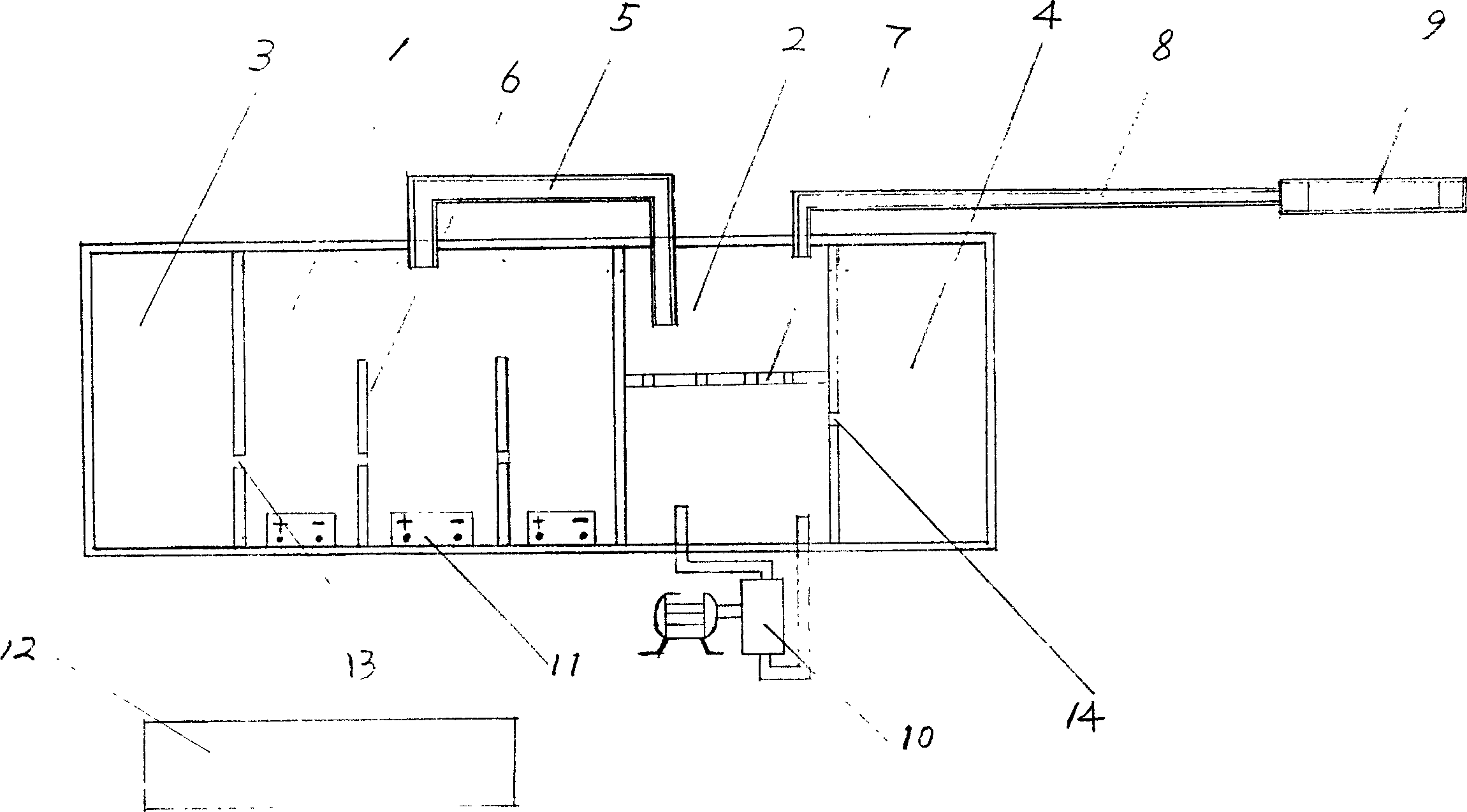

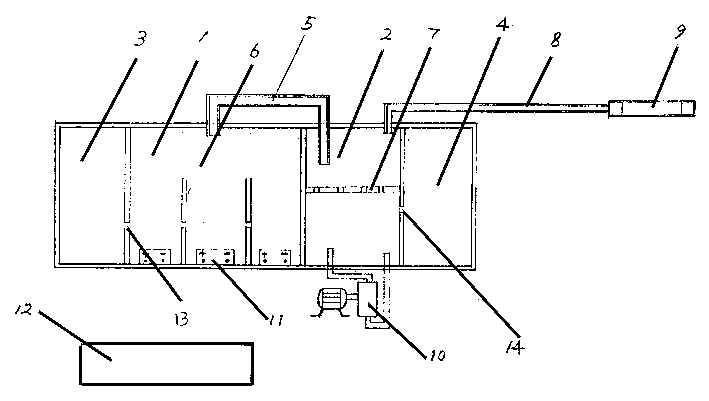

[0007] The process of the present invention is realized as follows: the ethanol in the main liquid tank for liquid boiling and vaporization of ethanol is heated to boiling by a temperature-controlled semiconductor micro-electric heater, and the vaporized ethanol gas is sent to the upper layer of the main tank 2 for liquid vaporization and vaporization of gasoline through the connecting pipe 5 , Mixed with gasoline vaporization gas, of which ethanol vaporization gas is the main fuel gas, accounting for 65-80%, and gasoline vaporization gas is auxiliary gas, accounting for 20-35%. When the mixed gas reaches a certain pressure, it is sent to the gas stove 9. The production volume of ethanol gas and the production volume of gasoline gas, as well as the mixing ratio and pressure of the two are controlled by the automatic control workbench 12 in the room.

[0008] In order to realize the process of the present invention, a device is specially designed, namely a new type of gas stove, wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com