High-precision temperature control circuit for thermoelectric cooler

A technology of thermoelectric refrigerator and temperature control, which is applied in the direction of temperature control using electric methods, machines using electric/magnetic effects, refrigerators, etc., which can solve the problems of low cooling efficiency, complex circuits, and low adjustment accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and implementation examples.

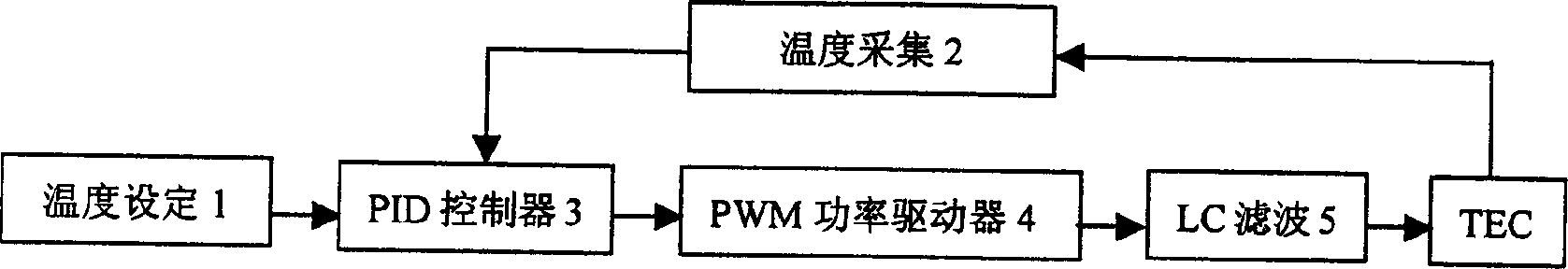

[0013] The present invention consists of five parts: temperature setting 1, temperature acquisition 2, PID (proportional integral differential) controller 3, PWM (pulse width modulation) power driver 4, and filter circuit 5.

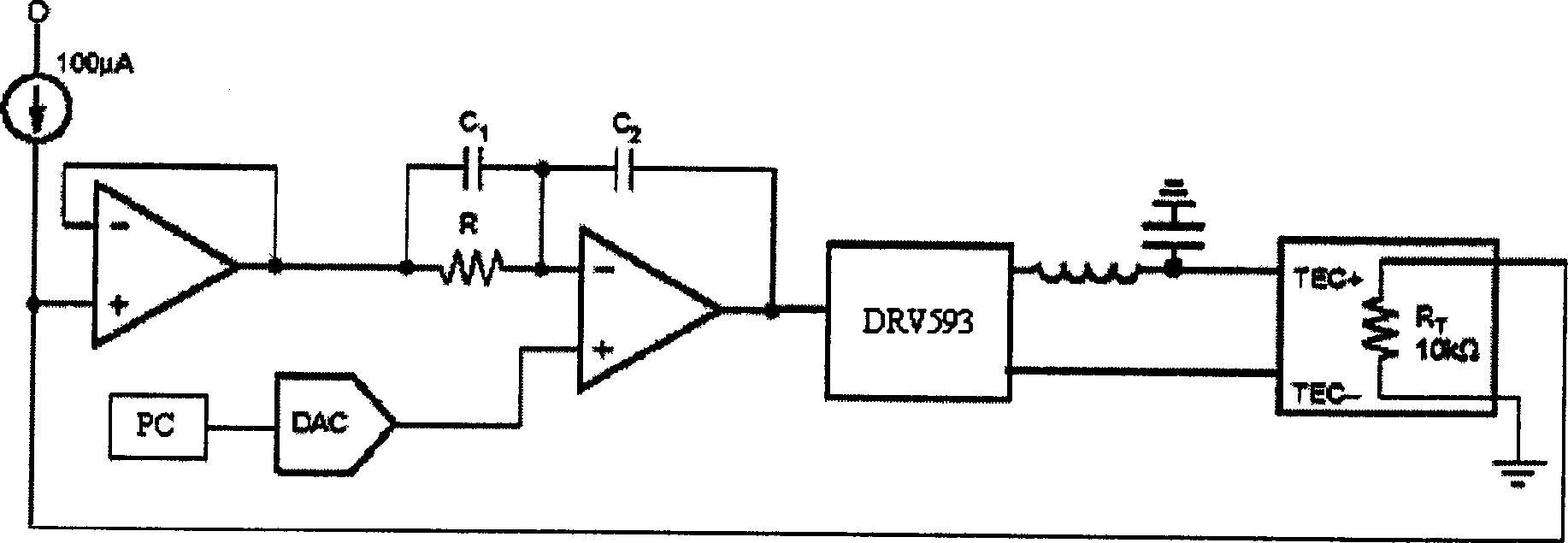

[0014] The temperature setting part 1 completes the setting of the working temperature required by the core components of the system. In order to ensure temperature accuracy, a 12-bit D / A is controlled by μC (microcontroller) or PC in a digital way, so that the output of the D / A corresponds to the core components of the system (semiconductor laser, uncooled infrared focal plane, etc.) The working temperature to be achieved, the output of D / A is the temperature setting signal.

[0015] The temperature acquisition part 2 is composed of a temperature sensor and an excitation source. Common temperature sensors include th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com