Process for treating and reutilizing bank-note gravure printing waste water

A technology for wastewater treatment and process method, which is applied in the directions of centrifugal separation water/sewage treatment, permeation/dialysis water/sewage treatment, etc. Flux, reduce membrane fouling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

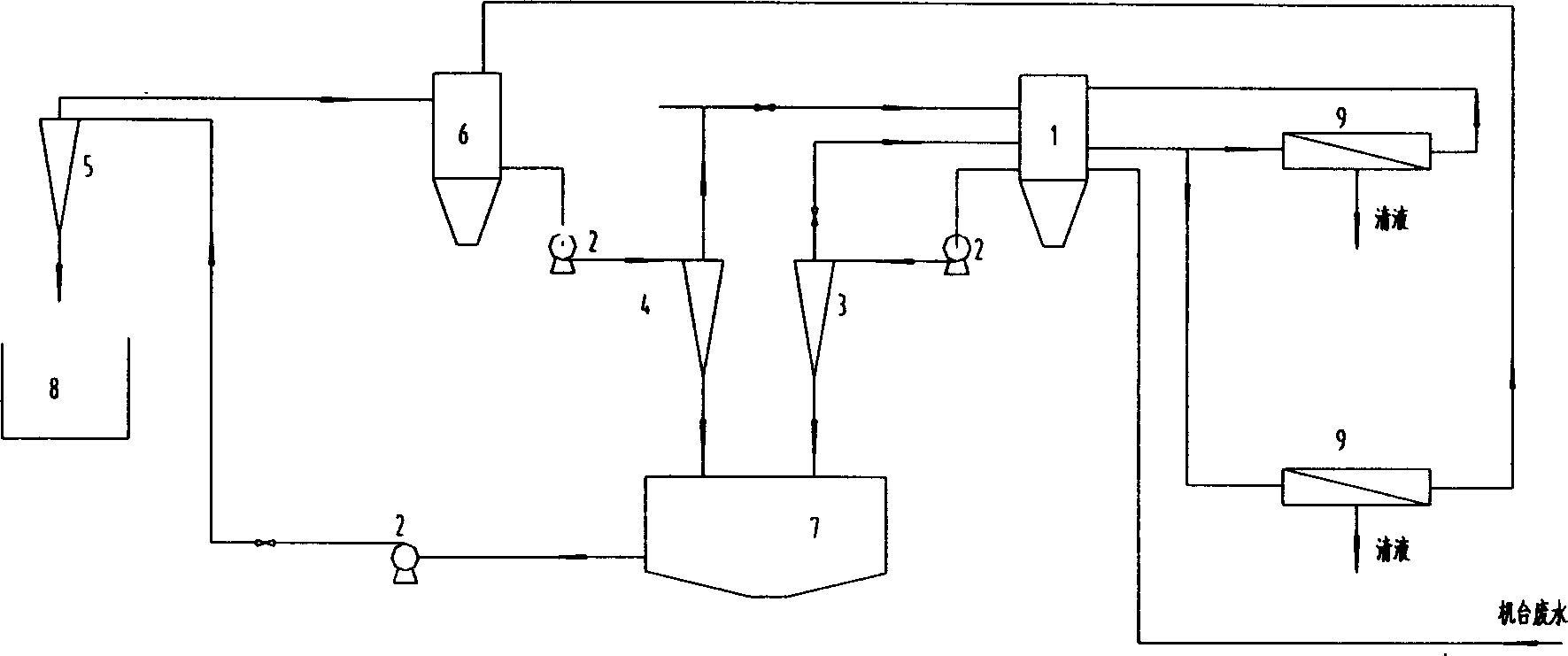

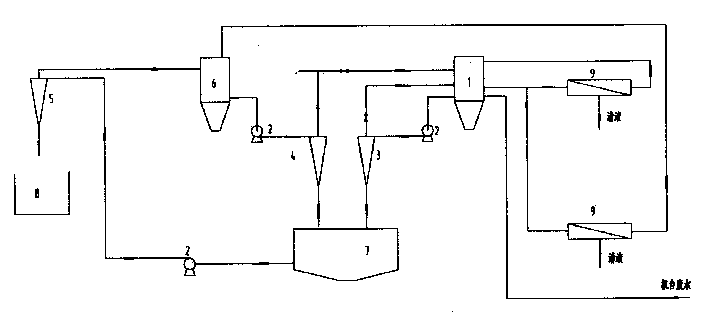

[0013] As shown in Fig. 1, a new type of banknote printing gravure waste water treatment and reuse process flow chart of the present invention, mainly consists of wiper waste liquid tank 1, lift pump 2, banknote printing gravure waste water pretreatment solid-liquid centrifugal separator 3 in sequence Concentrated liquid solid-liquid centrifugal separator 4, concentrated liquid re-concentrated solid-liquid centrifugal separator 5, ultrafiltration membrane concentrated liquid receiving tank 6, concentrated liquid receiving tank 7, slag discharge tank 8, and ultrafilter 9 devices.

[0014] Working process of the present invention is as follows:

[0015] The wiper waste liquid containing solid phase (machine waste water) enters the wiper waste liquid tank 1 through the pipeline for collection, and is boosted by the lift pump 2 to output a stable value of pressure and flow rate wiper waste liquid to the banknote printing gravure The solid-liquid centrifugal separator 3 for wastewa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com