Microscopic electrochemical analyzer

A microelectrochemical and analyzer technology, applied in the direction of material electrochemical variables, scientific instruments, analytical materials, etc., can solve problems such as poor results, difficult to achieve targeted process parameters, and affect the safety of refining process equipment. To achieve the effect of quick screening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

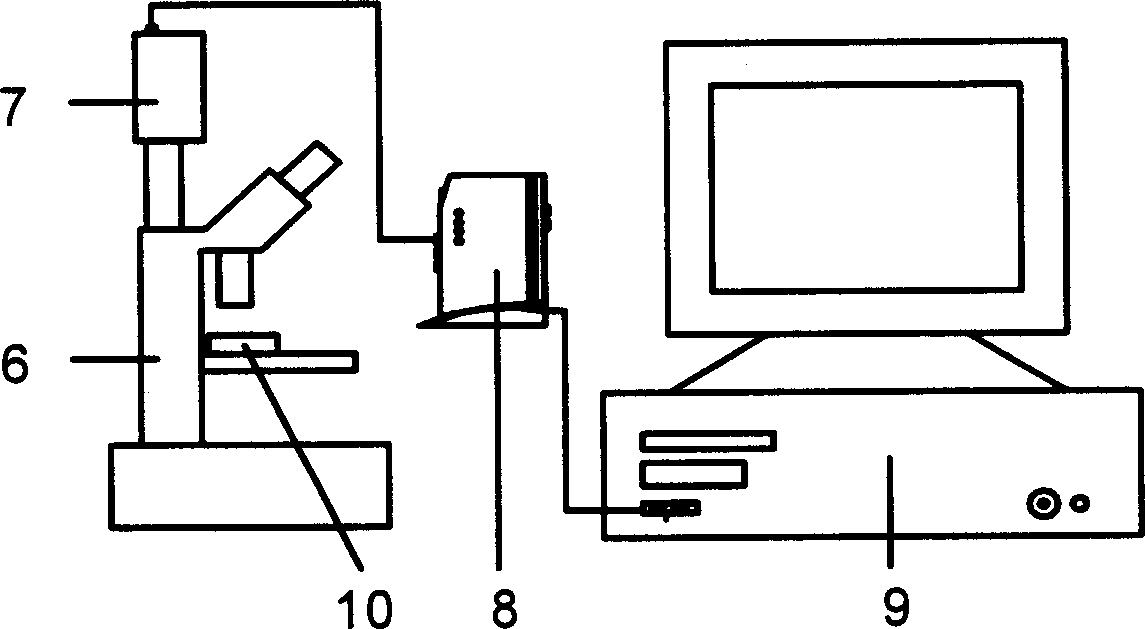

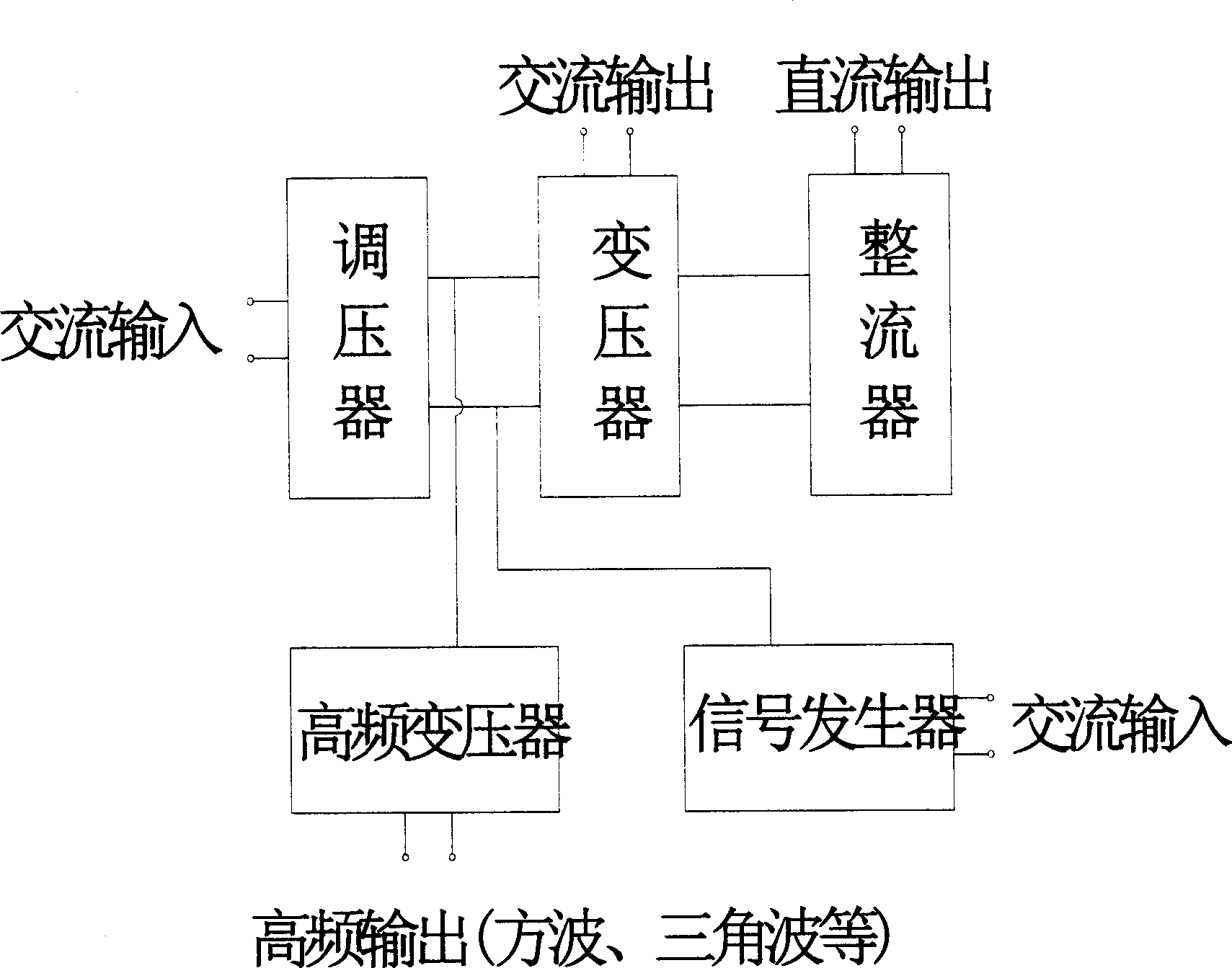

[0014] See figure 1 Shown, a kind of microelectrochemical analyzer of the present invention is made up of power unit, electrolytic cell 10, optical microscope 6, CCD (being digital) camera 7, video card 8 and computer 9, and optical microscope 6 is the same as CCD camera 7 is connected through standard CS interface, CCD camera 7 and computer 9 are connected through video card 8, and CCD camera 7 transmits data to computer 9 for software control and then displayed on the display, and micro-electrolytic cell 10 is externally connected to power supply device to form electrochemical migration, A working cell for electrochemical reactions, the micro-electrolytic cell 10 has a special function of preventing high-voltage breakdown.

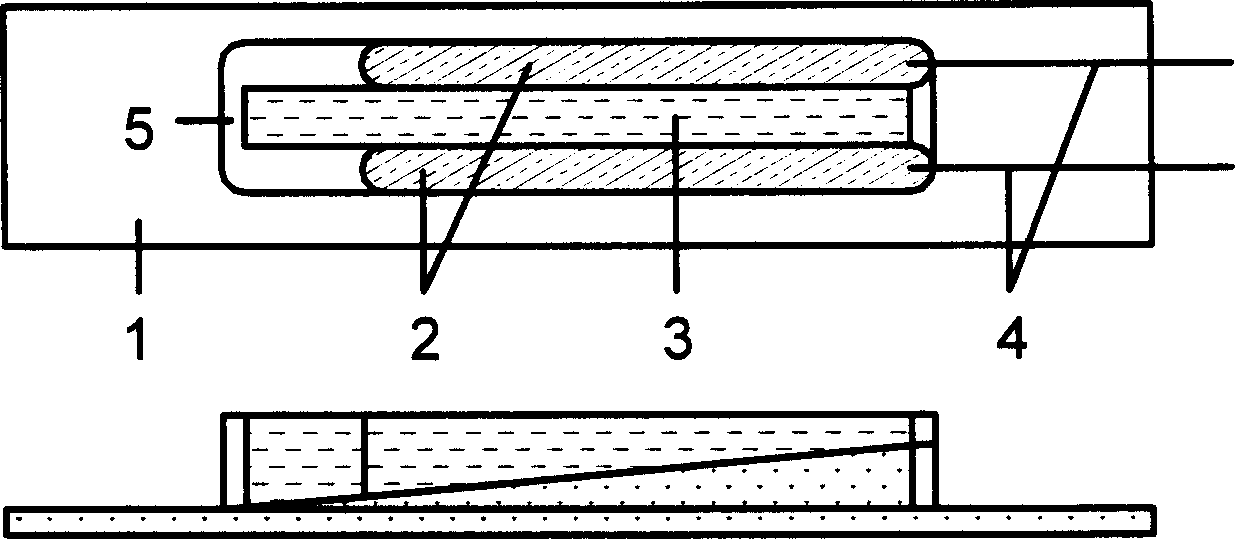

[0015] In the present invention, the microelectrolytic cell 10 is made of a neutral glass slide 1, a copper electrode 2, and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com