DC motor servo driving system based on network

A technology of servo drive and DC motor, applied in the transmission system, electrical components, electrical digital data processing, etc., can solve the problems such as inconvenient joint control of multi-axis motor drive system, difficulty in memory and bus expansion, and slow data transmission speed. Achieve the effect of outstanding modularity, easy application and maintenance, and less communication connections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail with reference to the accompanying drawings and embodiments.

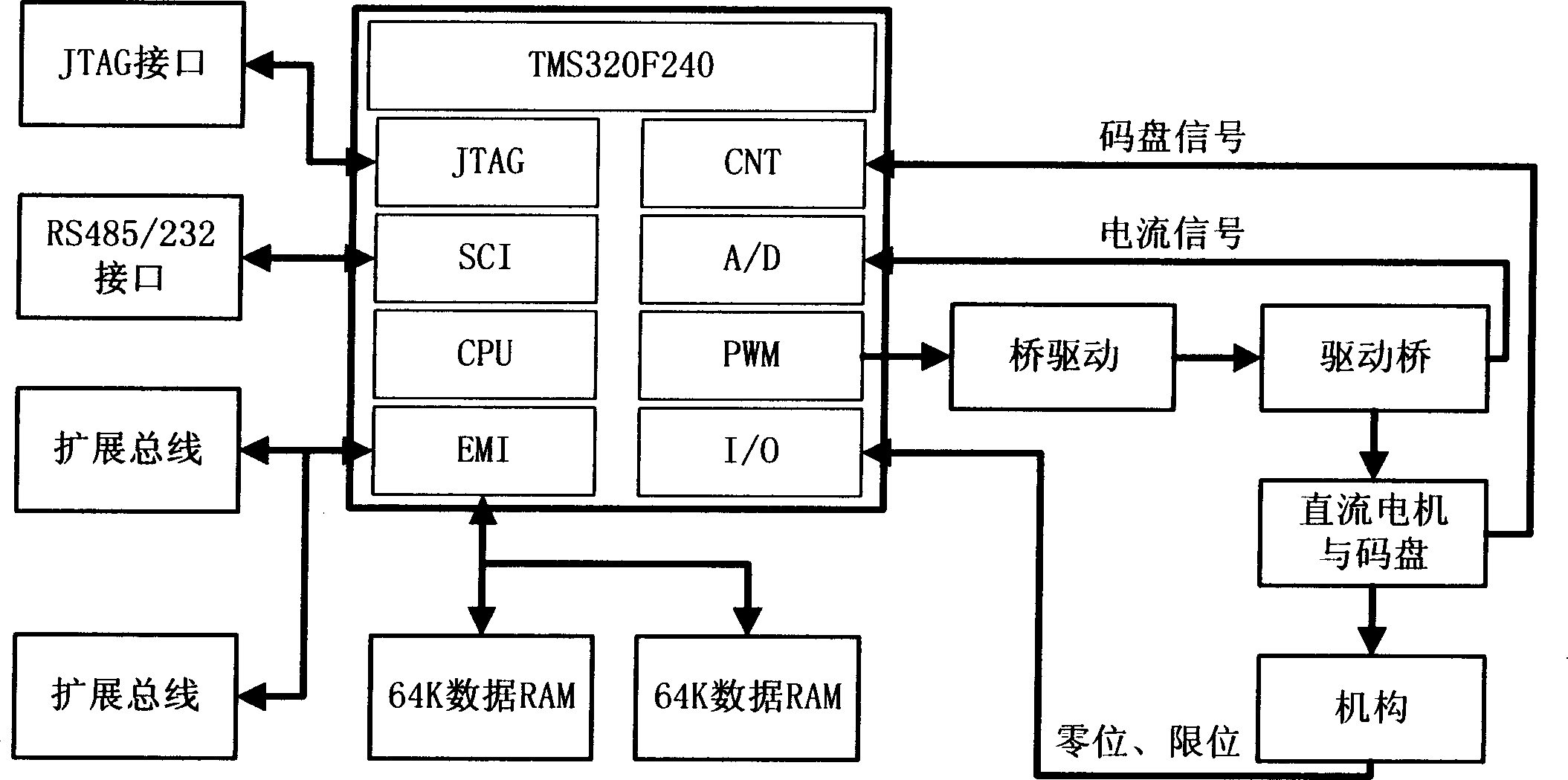

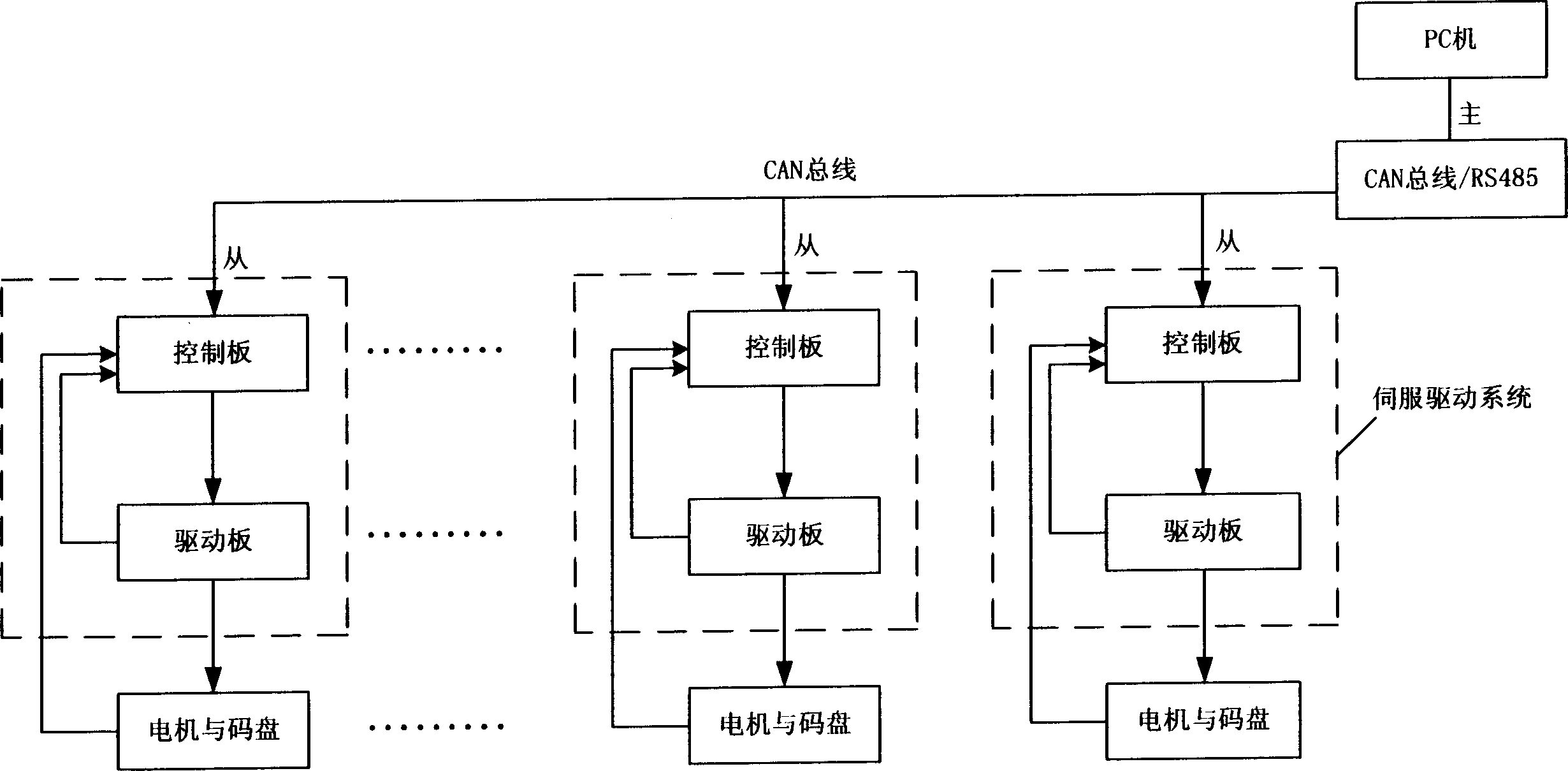

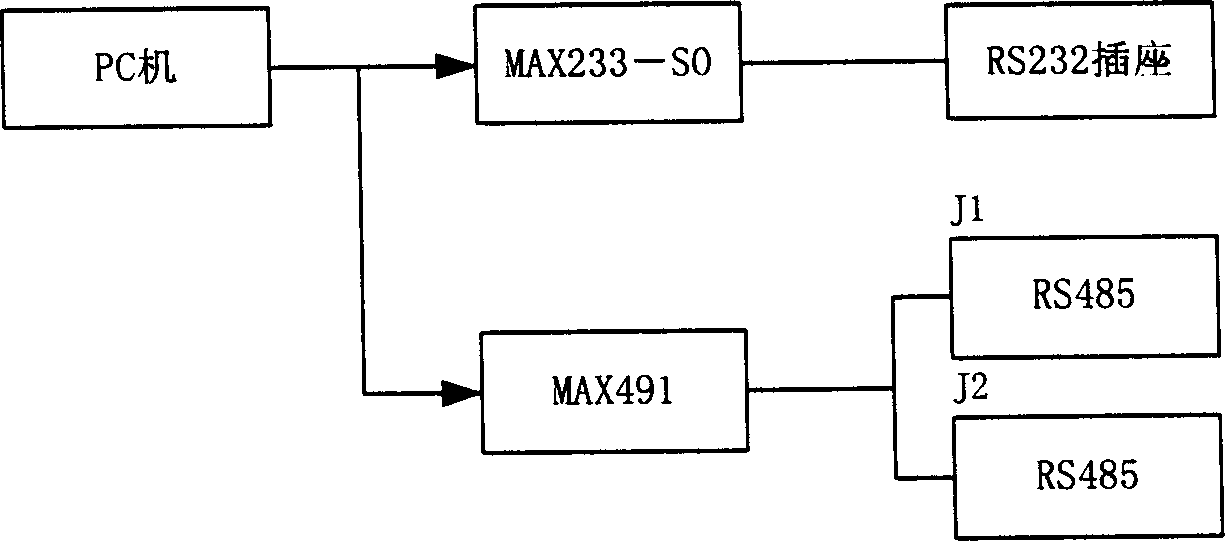

[0032] The invention is a network-based DC motor servo drive system, which includes a PC, a servo drive system, a DC motor and a code disc. The servo drive system is mainly composed of a control module, a drive module and a network interface module, and the three modules are connected into one body through two 40-pin sockets. On the basis of complying with the RS485 communication protocol, the single-line serial communication and serial network connection between the PC and the multi-axis drive mechanism are realized through the CAN bus interface. The networking mode of the multi-axis system is one master and multiple slaves, that is, only one control module is the master module, the master module is the control module connected to the PC, and the other modules are slave modules, and the master-slave relationship cannot be changed at will (such as fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com