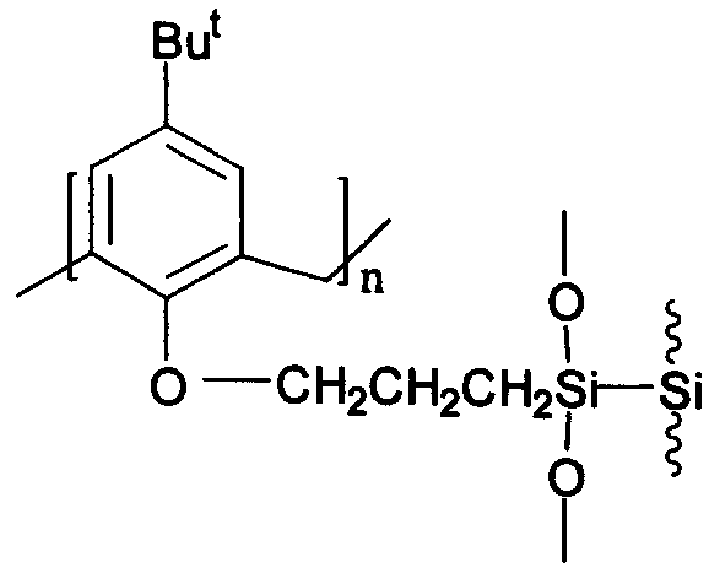

Aromatic hydrocarbon linked silica gel solid phase and its preparation and use

A technology for bonding silica gel and calixarene, which is applied in chemical instruments and methods, other chemical processes, instruments, etc., can solve the problems of not providing synthesis routes and technologies, and achieves improved chromatographic peak symmetry, simple preparation method, and stability. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0022] Example: using chloropropyltriethoxysilane as coupling agent and tetrabutylammonium bromide as phase transfer catalyst, p-tert-butyl calix[8]arene as raw material, and Kromasil 5 μm spherical silica gel as substrate to prepare calix Aromatic silica bonded stationary phase. The p-tert-butylcalix[8]arene bonded stationary phase was prepared according to one to four steps. Characterized by infrared spectroscopy, thermal analysis and elemental analysis, the stationary phase was successfully synthesized.

[0023] Using chloropropyl silica gel and KBr pellets as references, the computer carried out background subtraction to obtain the FTIR spectrum of the p-tert-butylcalix[8]arene bonded stationary phase. Spectrum display: ν2961.5cm -1 ;ν2929.7cm -1 ;ν2847.0cm -1 Stretching vibration absorption peak of saturated C-H; ν1599.1cm-1 ;ν1577.7cm -1 ;ν1487.6cm -1 Benzene ring skeleton vibration absorption peak; ν1477.9cm -1 ;ν1384.3cm -1 CH 2 、CH 3 Bending vibration peak;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com