Water-latex tye rust removing and rust protection liquid as well as its preparation method

A kind of technology of anti-rust liquid and water-emulsion type, applied in the direction of metal material coating process, etc., can solve the problems of not being widely used, large one-time investment of equipment, complicated production process, etc., and achieves convenient use and operation without harming the human body Healthy, non-polluting effect on the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

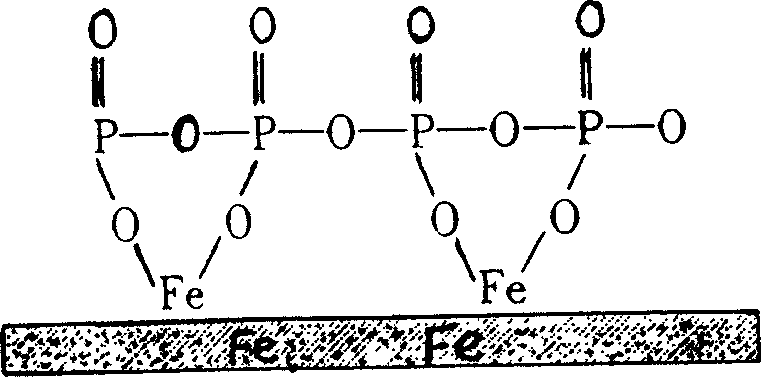

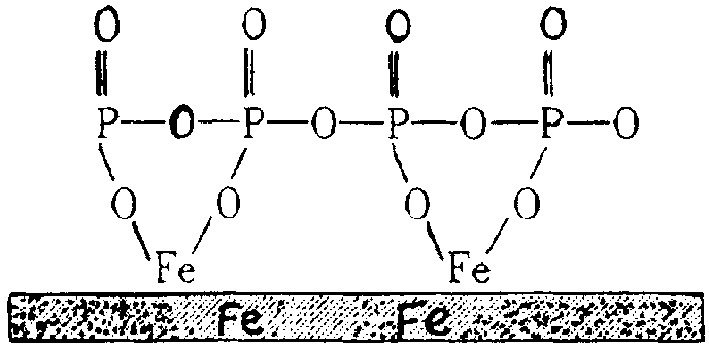

Method used

Image

Examples

Embodiment 1

[0008] The following are non-limiting examples of the present invention: Embodiment 1: take H 3 PO 4 33 parts, 15 parts of aluminum powder, NH 4 NO 3 1 part, AlK(SO 4 ) 2 0.05 parts, water (H 2 O) 50 parts (all are parts by weight), H 3 PO 4 33 parts and 15 parts of aluminum powder were mixed, fully reacted to prepare aluminum phosphate liquid for later use, and then NH 4 NO 3 1 part, AlK(SO 4 ) 2 0.05 parts, water (H 2 O) 50 parts are mixed evenly with the prepared phosphoric acid solution to obtain the water-emulsion type rust-removing and anti-rust solution of the present invention. The water-emulsion type rust-removing and anti-rust liquid of the present invention is used for the steel ball of 15 meters of diameters on the roof of a building for experiment, removes floating rust with wire brush before painting, brushes two layers with this bright water-emulsion type rust-removing and anti-rust liquid, and then After being covered with varnish for decoration...

Embodiment 2

[0009] Embodiment 2: take H 3 PO 4 34%, aluminum (Al) powder 13%, NH 4 NO 3 1%, AlK(SO 4 ) 2 0.1%, water (H 2 O) 51.9% prepare 5 tons of water-emulsion type rust-removing and anti-rust liquid of the present invention and be used for the immersion type rust-removing and anti-rust liquid of iron and steel parts. There are only 2 procedures, that is, soaking for 5-20 minutes (rust removal, rust prevention and phosphating) and natural drying. The product can be 100% utilized. The product is colorless, transparent, non-volatile, and PH=0.5. After the original solution has been used for many times, if the pH value is greater than 1, only the original solution needs to be added to make the pH ≤ 1, then it can continue to be used. affect the quality. Basically realized "zero discharge" of pollution and improved the production conditions of operators.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com