Aluminum nitride monocrystal film and method of preparing the same

A technology of single crystal thin film and aluminum nitride, which is applied in semiconductor/solid-state device manufacturing, ion implantation plating, coating, etc., and can solve problems such as many defects in the film and difficulty in obtaining high-quality single crystal thin film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

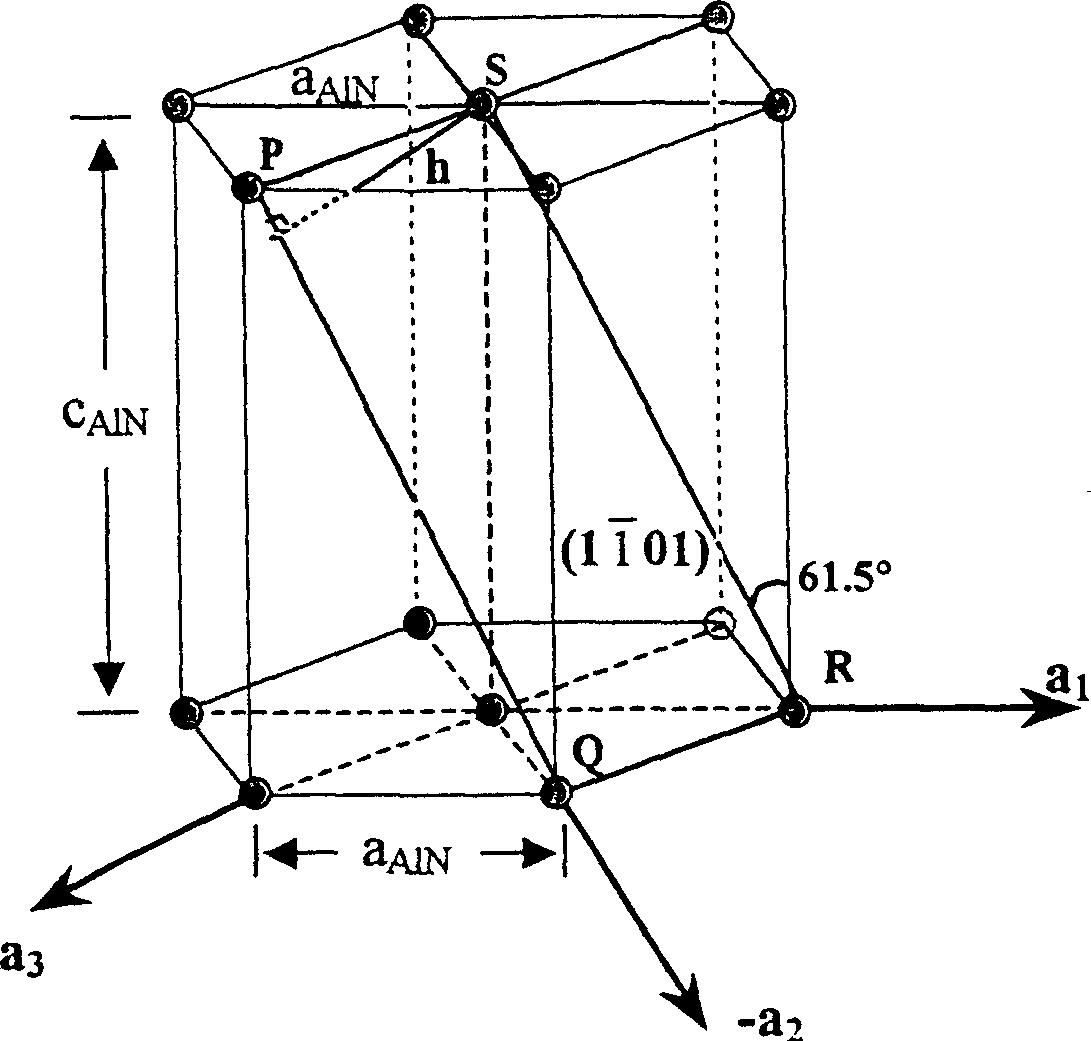

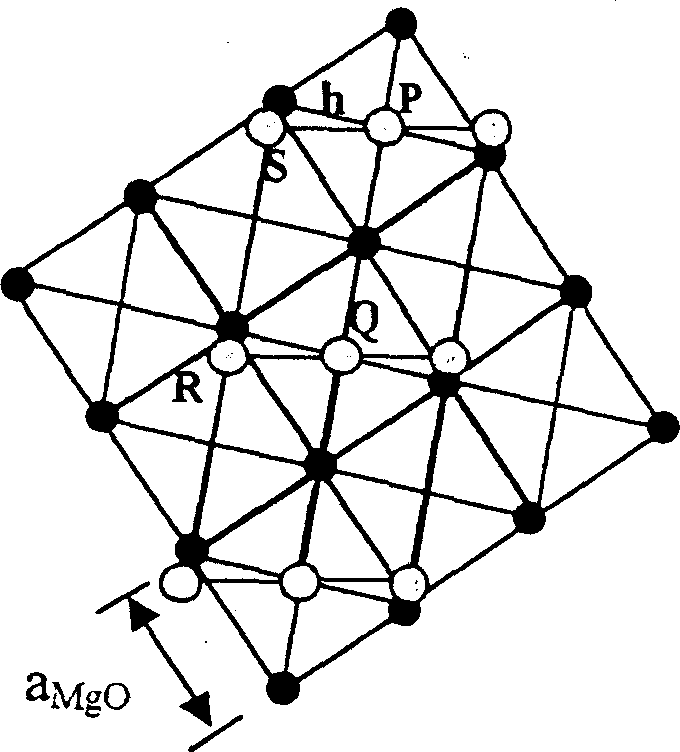

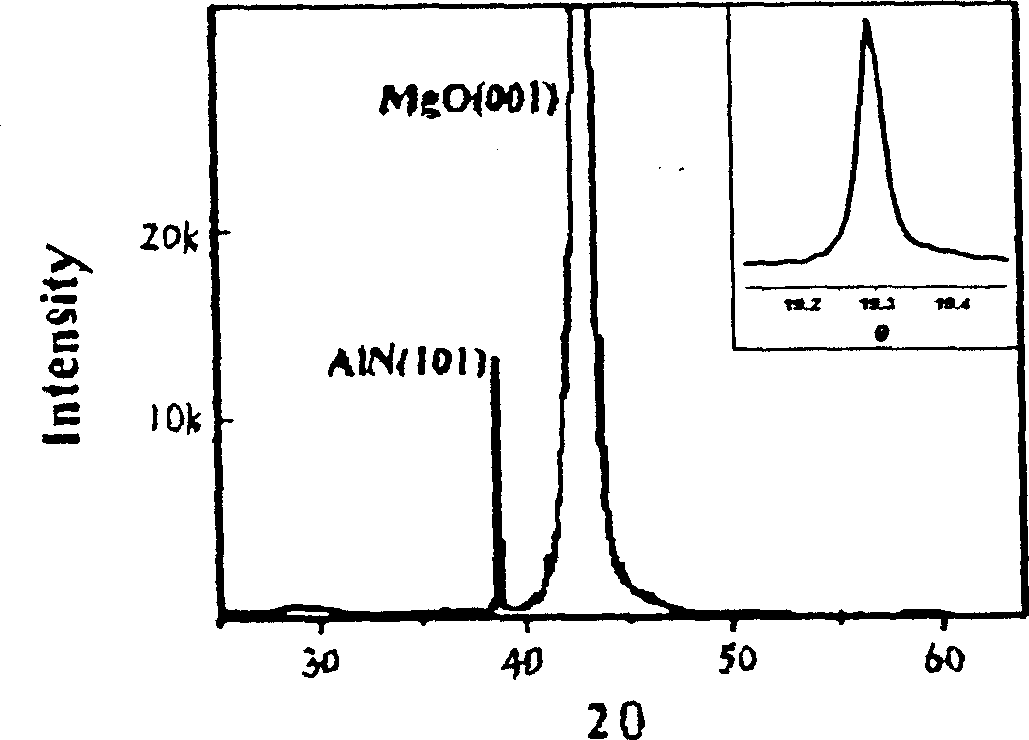

[0028] An aluminum nitride thin film on a magnesium oxide single crystal substrate, comprising a magnesium oxide single crystal substrate substrate 2 and an aluminum nitride thin film 1, the lattice structure of the magnesium oxide single crystal substrate 2 is a cubic crystal, and the lattice parameter α MgO =4.201 Å; the crystal of aluminum nitride is a hexagonal structure, and the lattice parameter is α AlN =3lll, c AlN = 4.979 Å. Although the lattice structures of aluminum nitride and magnesium oxide are different, the [101] crystal orientation of the aluminum nitride film 1 and the [001] crystal orientation of the magnesium oxide single crystal substrate 2 have a good match.

[0029] A method for growing an aluminum nitride thin film 1 on a magnesium oxide single crystal substrate 2 by radio frequency magnetron sputtering, the steps are:

[0030] (a) Cleaning of the magnesium oxide single crystal substrate: first put the magnesium oxide single crystal substrate into ace...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com