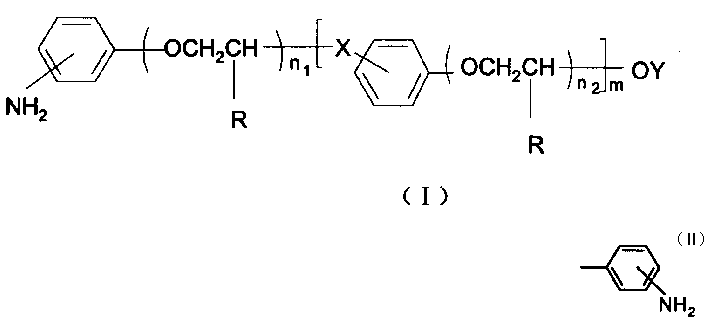

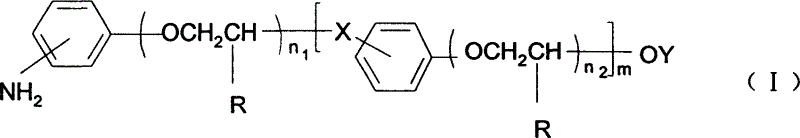

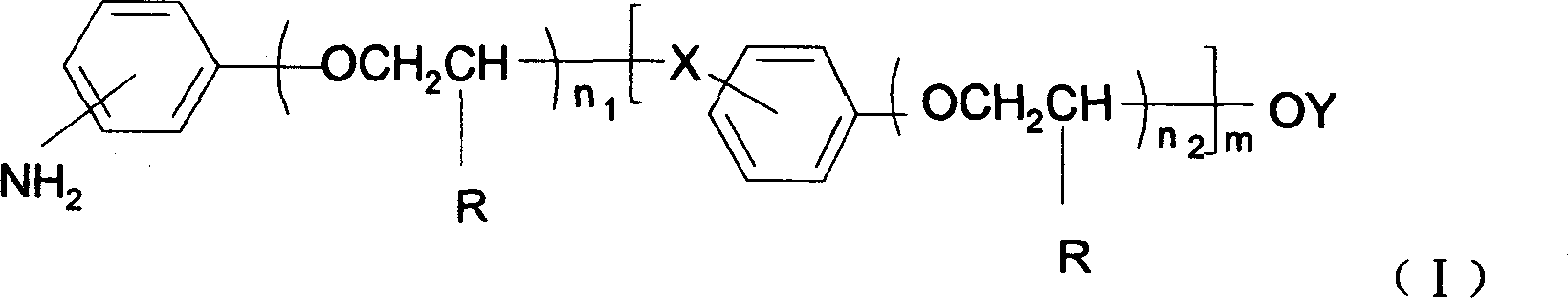

Terminal aromatic amino base polyether compound, its preparation method and use in adhesive agent

A technology of amino polyether and hydroxyl-terminated polyether, which is applied in the field of aromatic amino-terminated polyether compounds and preparation, and achieves the effects of low cost, high bonding strength and wide application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Add 0.05mol of polyethylene glycol (PEG) and 0.6mL (0.01mol) of DMF into a 100mL three-necked flask, heat up to 70°C with an oil bath while stirring, and then drop 8mL (0.11mol) of chlorine within 10min. Sulfoxide was reacted at 80°C for 6 hours. The SO2 and HCl gases generated during the reaction are absorbed with lye. After the reaction solution was cooled, it was washed with saturated brine, the crude product was collected, dried with anhydrous potassium carbonate and adjusted to neutrality, and then the filtrate was collected by filtration to obtain chlorine-terminated polyethylene glycol.

[0018] In a 250 mL saline bottle, mix 0.1 mol of o-aminophenol, 0.4 mol of NaOH and 0.54 g of TBAB (5% W / W-aminophenol) at room temperature, then add the chlorine-terminated polyethylene Diol 0.05mol. Simultaneously, the mixture was heated to 60° C. with a water bath and stirred for 48 hours. After the reaction solution was cooled, the organic compound was extracted with abou...

Embodiment 2

[0020] With embodiment 1, replace o-aminophenol with m-aminophenol as raw material, obtain double-end (m-aminophenyl) polyethylene glycol ( ), referred to as 3-ATPE.

Embodiment 3

[0022] With embodiment 1, wherein respectively replace Polyethylene Glycol with polypropylene glycol, p-aminophenol replaces o-aminophenol as raw material, obtains double-end (p-aminophenyl) polypropylene glycol ( ), referred to as 4-ATPE.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Peel strength | aaaaa | aaaaa |

| Peel strength | aaaaa | aaaaa |

| Adhesion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com