Silent polyvinyl chloride drain pipe

A technology of polyvinyl chloride and polyvinyl chloride resin, applied in the field of drainage pipes, can solve the problems of affecting the quietness of the room, poor practicability, inconvenient installation, etc., and achieves convenient installation and use, simple manufacturing process steps, good impact strength and tensile strength The effect of elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

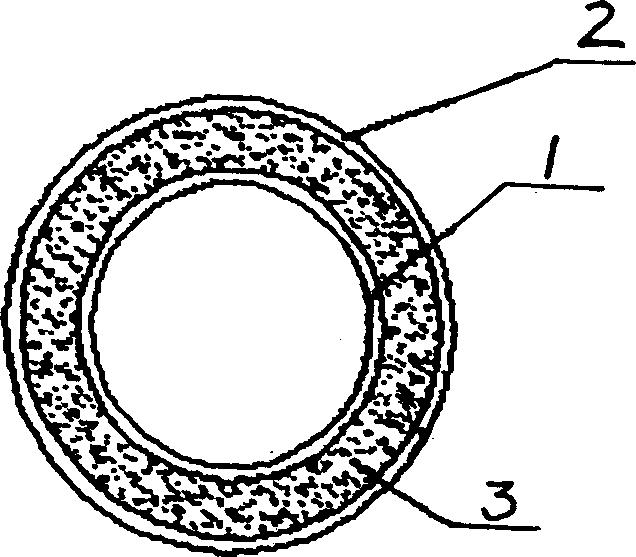

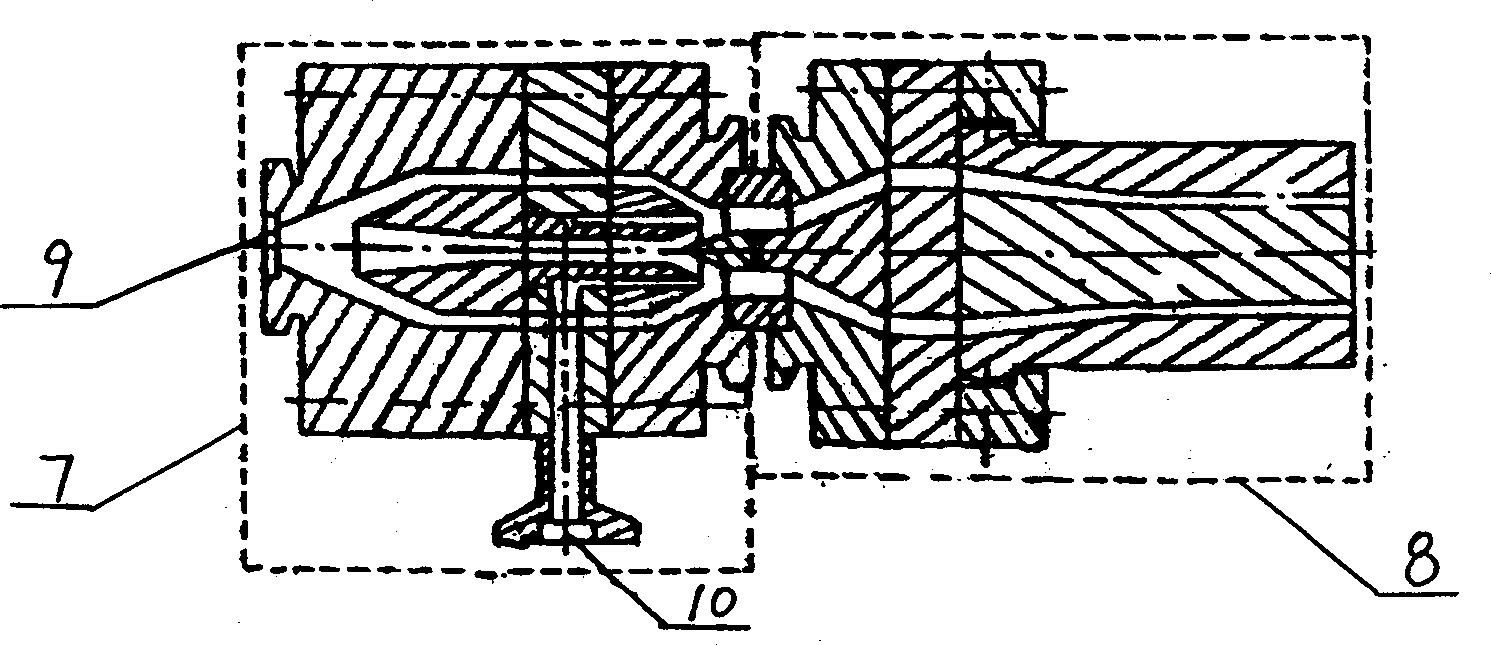

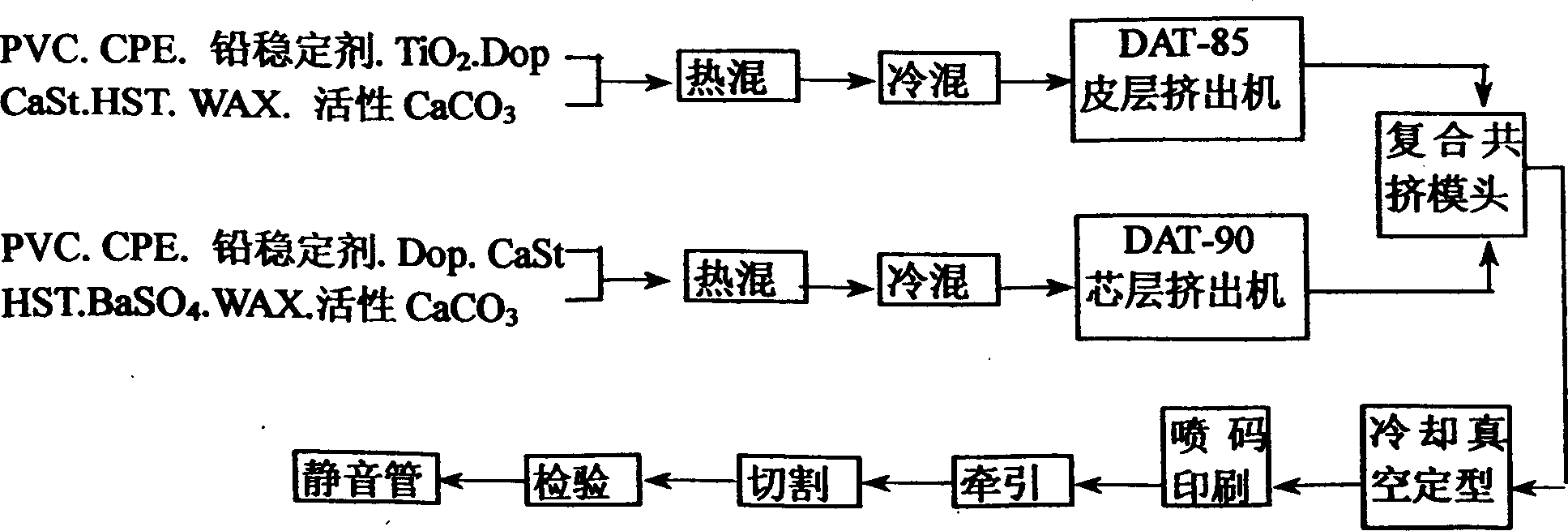

[0018] Embodiment 1: see figure 1 , figure 2 and image 3 , the structural feature of the present invention is that the sound-absorbing core layer 3 is co-extruded between the outer skin layer 2 and the inner skin layer 1; Die head is made up of co-extrusion die 7 and composite die 8.

[0019] Its preparation process steps are:

[0020] Step 1, raw material preparation:

[0021] Prepare the inner and outer skin layer materials according to the following dosage:

[0022] Polyvinyl chloride PVC (SG5) resin 100Kg, chlorinated polyethylene (CPE) 8Kg, composite lead stabilizer 4.2Kg, calcium stearate (Cast) 0.3Kg, stearic acid (HST) 0.3Kg, paraffin wax (WAX) 0.1 Kg, bis(2-ethylhexyl) phthalate (DOP) 2.5Kg, activated calcium carbonate (CaCO 3 ) 30Kg, titanium dioxide (TiO 2 )1.2Kg;

[0023] Prepare the sound-absorbing core layer material according to the following dosage:

[0024] Polyvinyl chloride (PVC) resin 100Kg, chlorinated polyethylene (CPE) 15Kg, lead stabilizer 4....

Embodiment 2

[0056] Embodiment 2: Its structure, preparation mold and preparation process are identical with embodiment 1, and its difference is that in the sound-absorbing core layer 3, the consumption of chlorinated polyethylene (CPE) is 20Kg, and active calcium carbonate (CaCO 3 ) dosage is 60Kg, barium sulfate (BaSO 4 ) consumption is 100Kg.

Embodiment 3

[0057] Embodiment 3: Its structure, preparation mold and preparation process are identical with embodiment 1, and its difference is that in sound-absorbing core layer 3, chlorinated polyethylene (CPE) 50Kg, barium sulfate (BaSO 4 ) dosage is 300Kg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com