Compoles fiber excellent in post-processablility and method of producing same

A technology for composite fibers and manufacturing methods, applied in the direction of fiber types, manufacturing tools, fiber processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

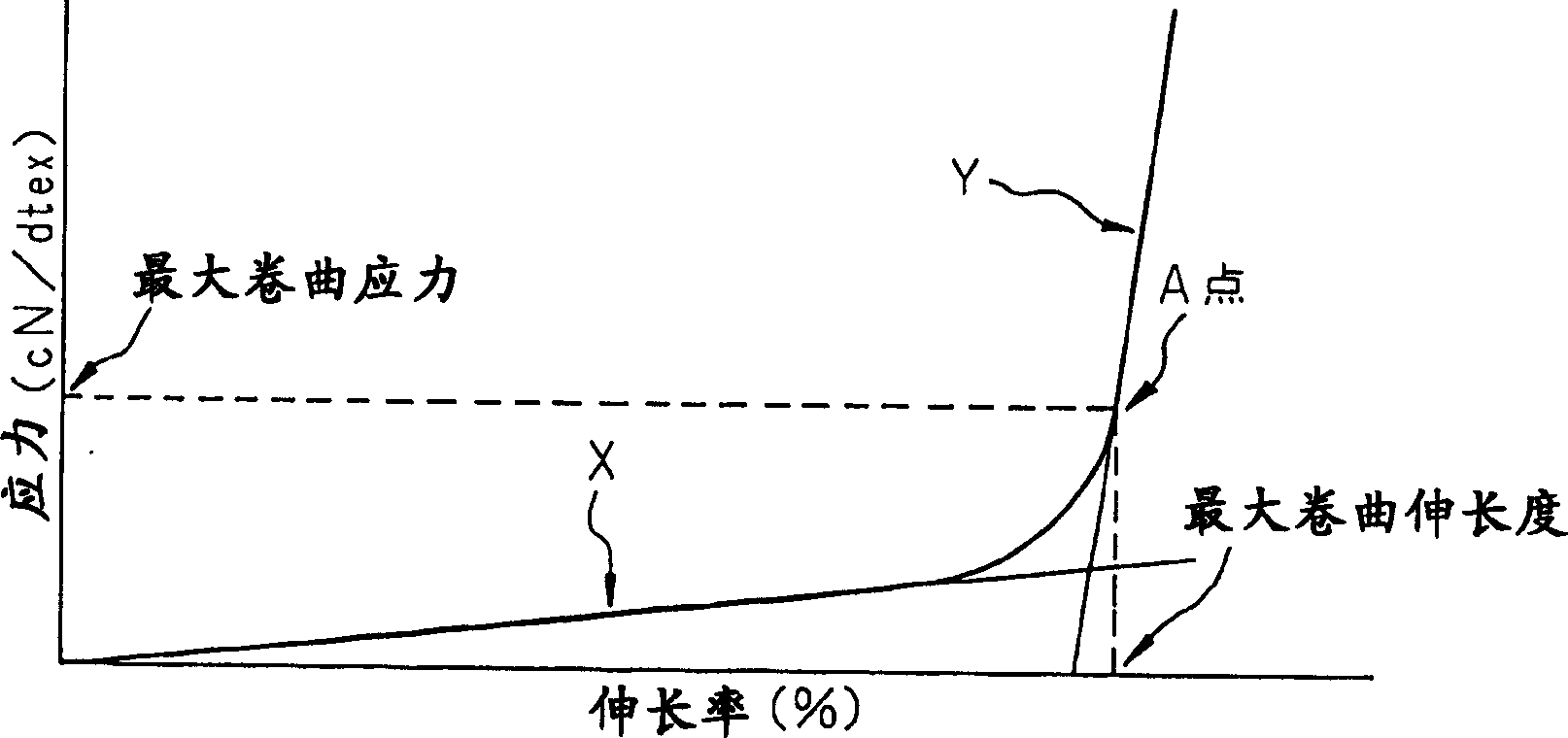

[0294] [Examples 1 to 4, Comparative Example 1]

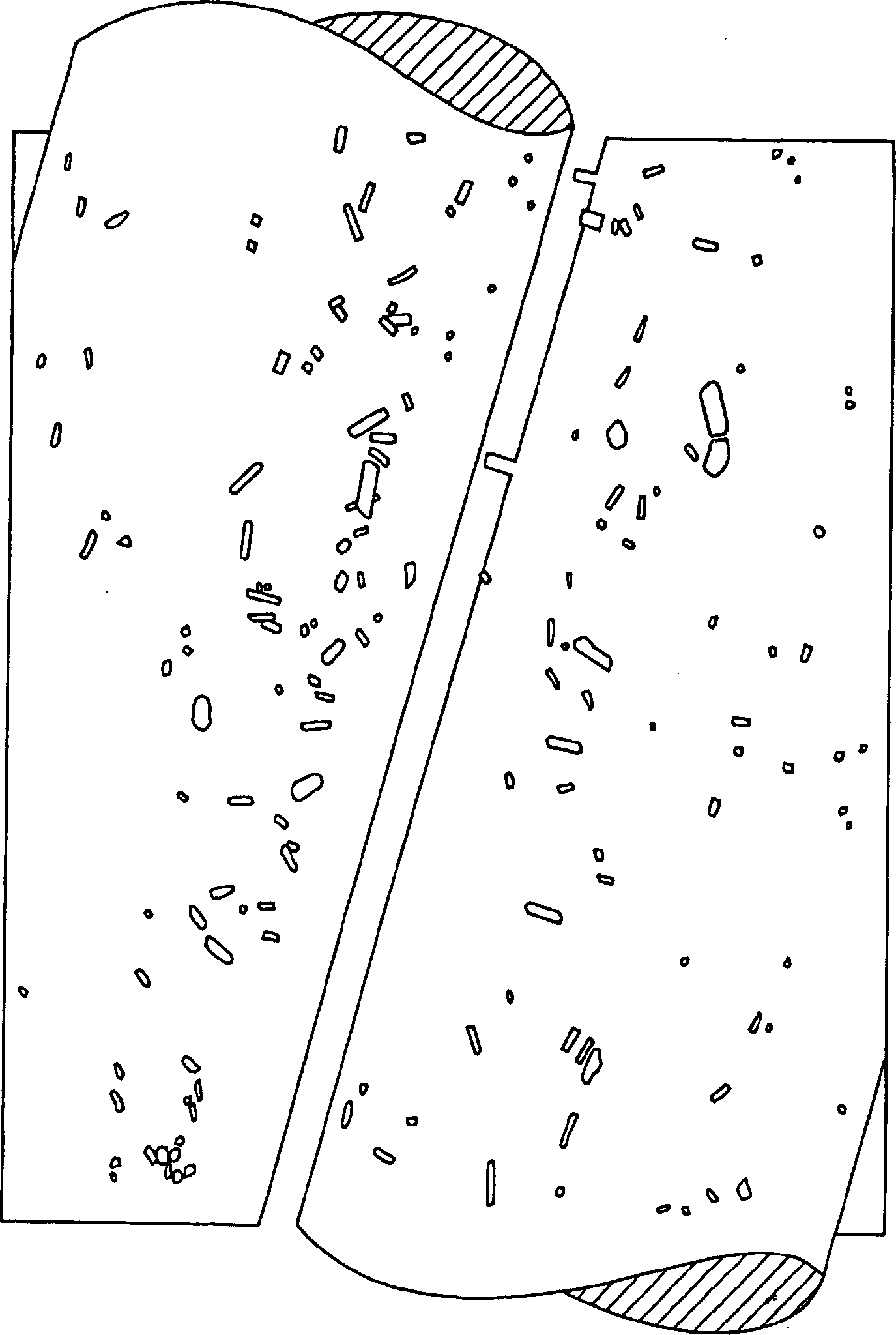

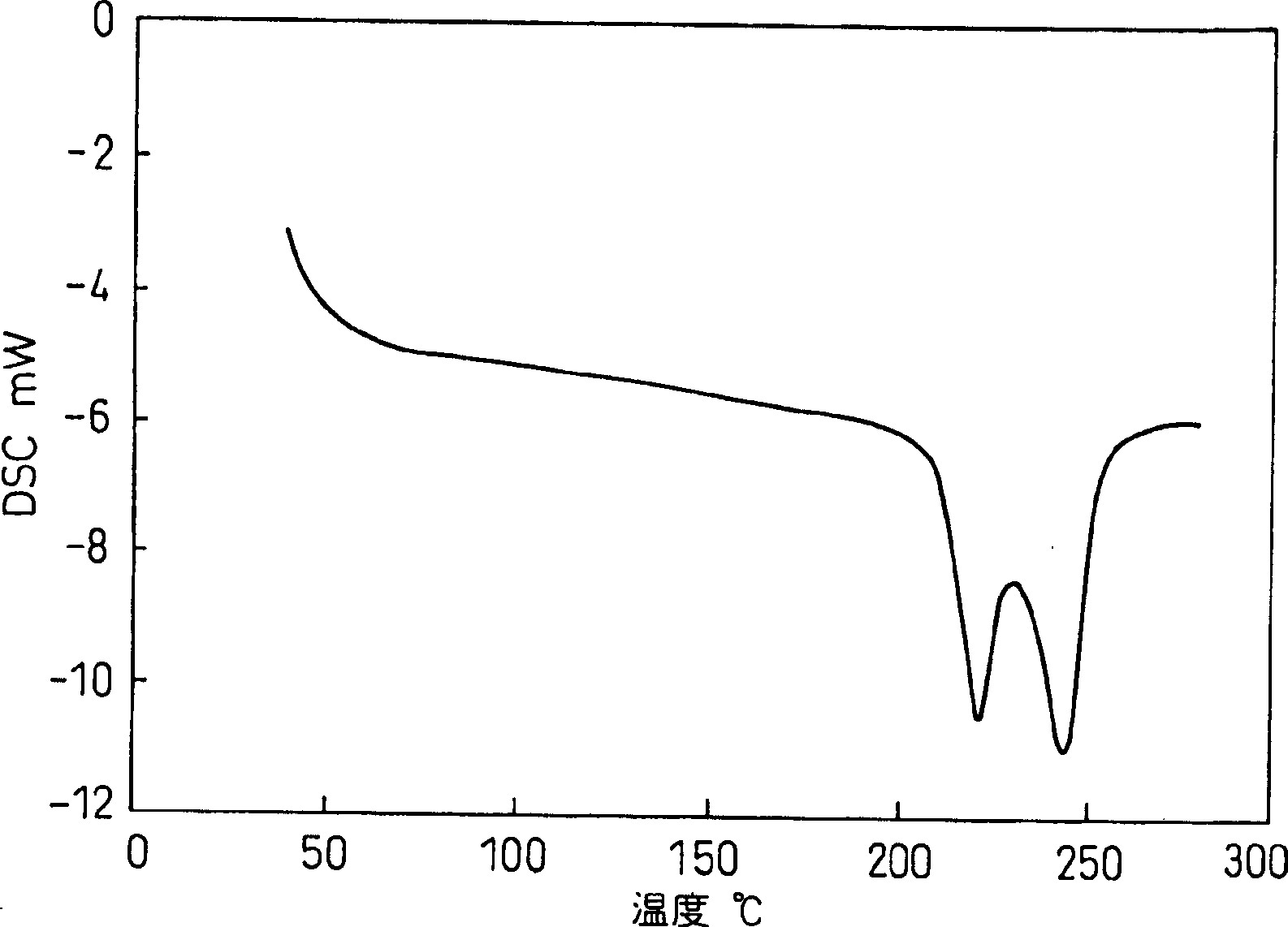

[0295] In this example, a side-by-side composite fiber composed of PTT for both components will be described, and the influence of the content rate of the cyclic dimer of trimethylene terephthalate will be described.

[0296] (spinning conditions)

[0297] Drying temperature and moisture content of polymer blocks: 110°C, 15ppm

[0298] Extruder temperature:

[0299] Rod A 250°C (high intrinsic viscosity side)

[0300] B rod 250°C (low intrinsic viscosity side)

[0301] Temperature of rotating part: 265°C

[0302] Melting residence time: 12 minutes

[0303] Spinning aperture: 0.50mmΦ

[0304] Spinning hole length: 1.25mm

[0305] The inclination angle of the spinneret hole relative to the vertical direction: 35 degrees

[0306] Number of spinneret holes: 12 holes

[0307] The length of the non-vent area: 255mm

[0308] Cooling air temperature and relative humidity: 22°C 90%

[0309] Cooling wind speed: 0.5m / s

[0310...

Embodiment 5~8、 comparative example 2 and 3

[0338] This example illustrates the effect of melting conditions.

[0339] In Example 1, the melting time was different as shown in Table 2, and other fabrics were obtained in the same manner as in Example 1. Table 2 shows the evaluation results of the obtained PTT-based composite fibers and their post-processing properties.

[0340] It can be seen from Table 2 that if the melting conditions specified in the present invention (Examples 5-8) are used, the content rate of the cyclic dimer of propylene terephthalate can be controlled, and PTT-based composite fibers with excellent post-processing properties can be obtained. .

Embodiment 9~12、 comparative example 4

[0343] In this example, the effect of the inclination angle of the spinneret holes in the vertical direction will be described.

[0344] Spinning was carried out in the same manner as in Example 1 except that the inclination angle of the spinneret holes in the vertical direction was different as shown in Table 3. The results are shown in Table 3.

[0345] As can be seen from Table 3, the spinneret holes (Examples 9 to 12) having the inclination angles specified in the present invention exhibit good spinning performance and good fineness change value U%. In Comparative Example 4 corresponding thereto, the fineness change value U% was large, and the dyeing quality was poor.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com