Preparation of 3-cyanopyridine

A technology of cyanopyridine and picoline, which is applied in the field of preparing 3-cyanopyridine, can solve problems such as the actual level of difficult fluidized bed catalysts, achieve good reaction stability, improve reaction selectivity, enhance oxygen adsorption capacity and Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Catalyst preparation:

[0048] 224g V 2 o 5 Add it into a solution at a temperature of 80-90° C. consisting of 490 milliliters of water and 468 grams of oxalic acid, stir well, and react to obtain a vanadium oxalate solution.

[0049] Set the concentration weight percent to 40% SiO 2 1250 grams of silica sol are slowly added in the above-mentioned solution under stirring, then add respectively by 886 grams of Cr (NO 3 ) 3 9H 2 A solution of O and 300 ml of water, 76.3 g of H 3 BO 3 and 560 ml of water and 85 g of 85% H 3 PO 4 and 50 ml of water, and finally add 24.9 g of KNO 3 20 milliliters of the aqueous solution, stirred, heated and evaporated to a solid content of 40% (weight), to obtain a thick slurry.

[0050] The catalyst formed by spray drying the above slurry was dried at 120°C for 12 hours and calcined at 650°C for 5 hours to obtain catalyst composition V 1.00 Cr 0.90 B 0.50 P 0.30 K 0.10 / SiO 2 , The catalyst main loading weight ratio is 50 / 50...

Embodiment 2~4

[0059] Using the same catalyst preparation method and evaluation conditions as in Example 1, the composition was changed to prepare the catalyst, and the evaluation results are listed in Table 1.

[0060] Example

Embodiment 5

[0062] Prepare catalyst with catalyst composition and preparation method of embodiment 1, change evaluation condition to be: 3-picoline: NH 3 : Air = 1:6:45 (mol), catalyst weight loading (WWH) 0.10 hours -1 , the reaction temperature is 425°C, and the reaction pressure is 0.01MPa.

[0063] The result of the reaction is:

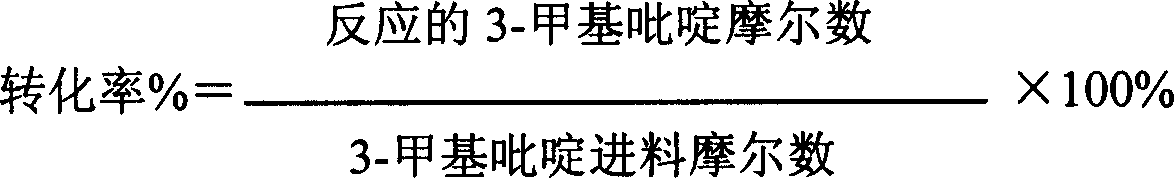

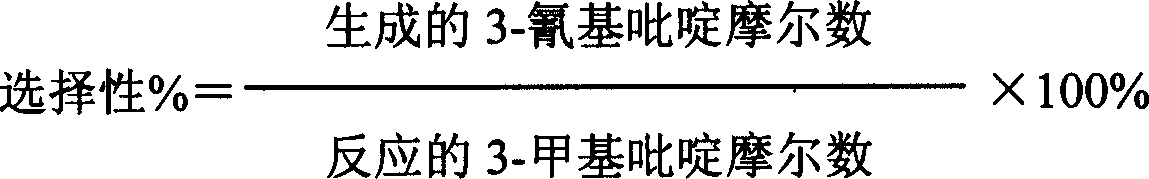

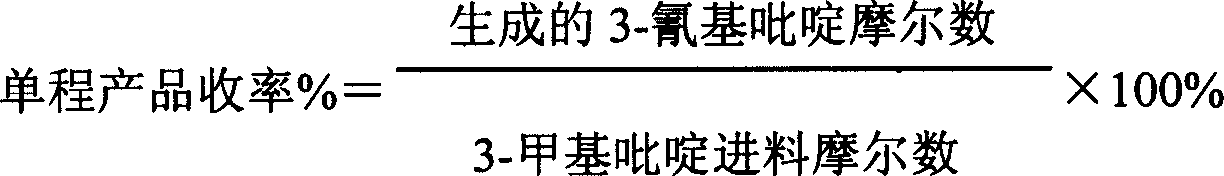

[0064] 3-picoline conversion 99.6%

[0065] 3-cyanopyridine selectivity 88.2%

[0066] 3-cyanopyridine yield 87.9%

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com