Automatic material transfer system and method

A material conveying system and the technology of the conveying system are applied in the field of automatic material conveying systems using lifting devices, which can solve the problems of no more installation, huge design, and inability to maintain a 3-meter height and width of a 12-inch semiconductor wafer, etc. Achieve the effect of increasing space and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

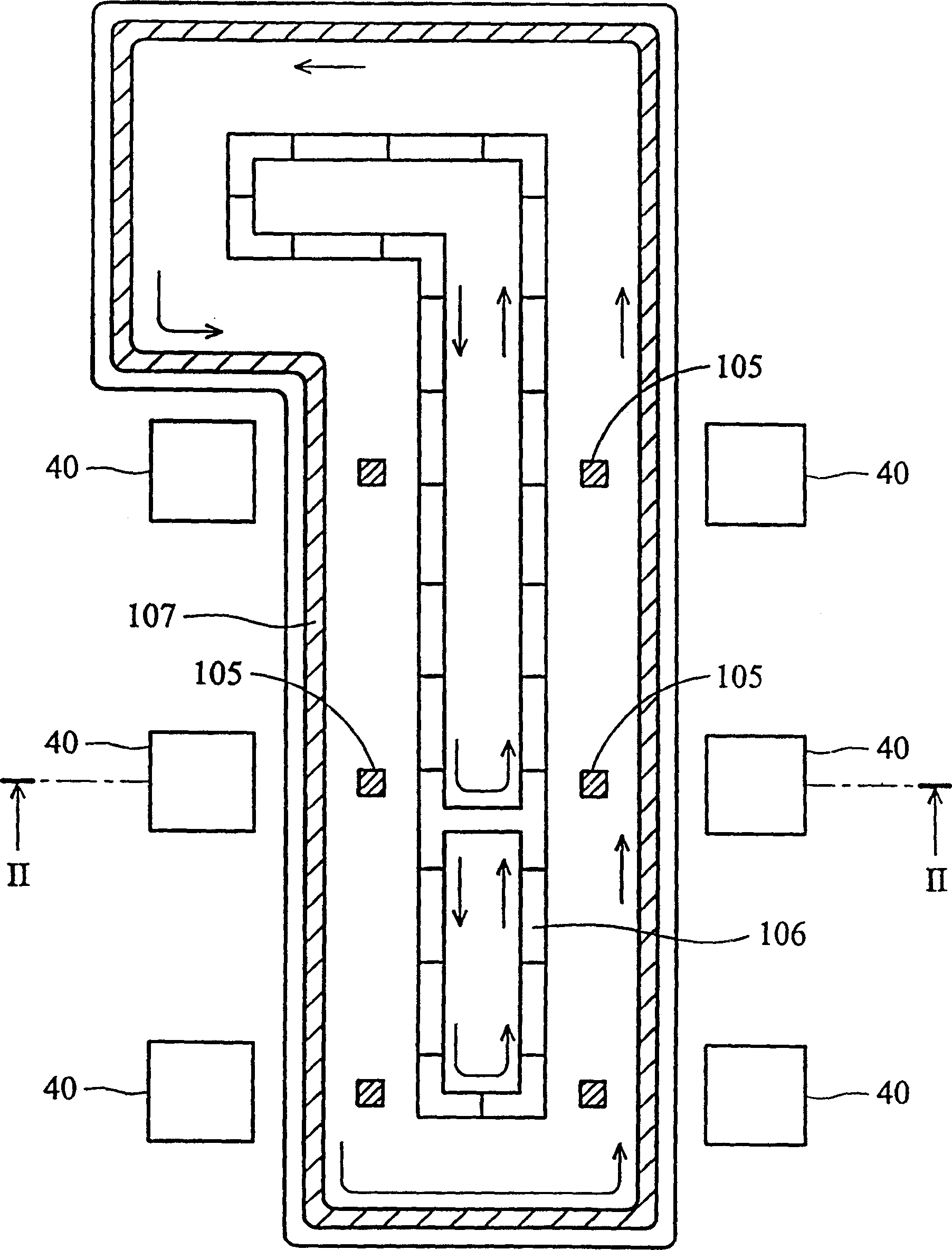

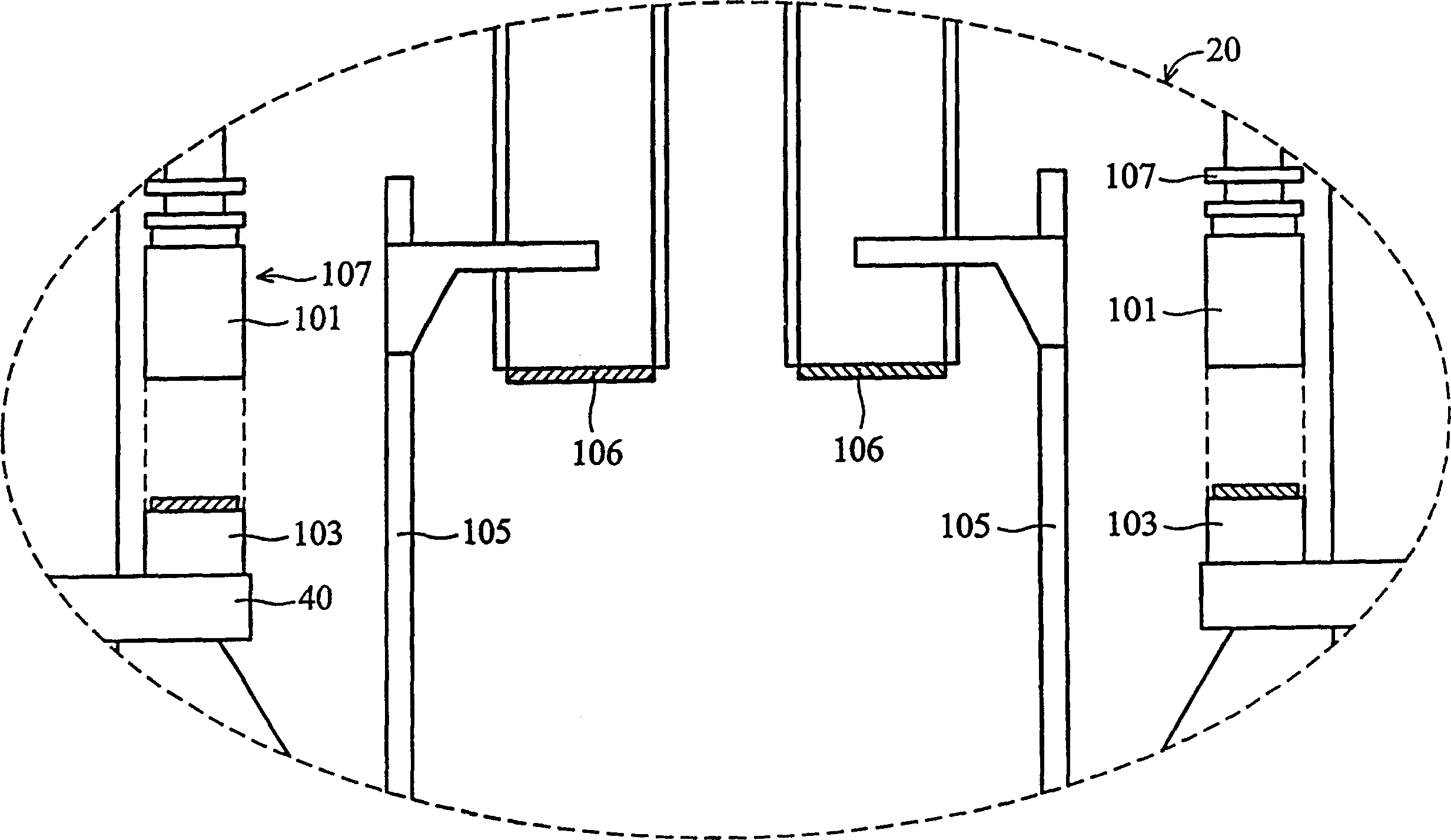

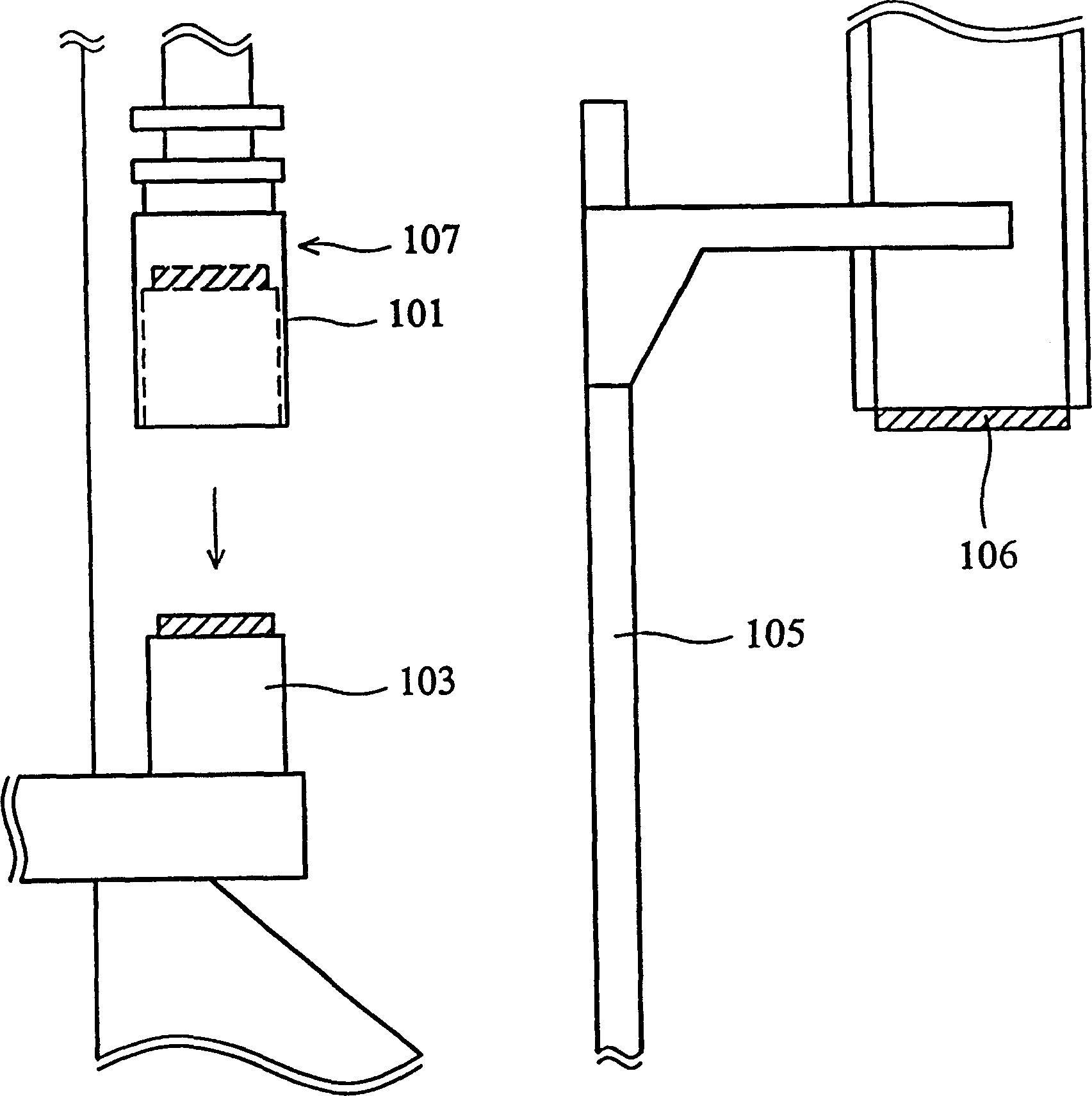

[0026] Such as image 3 As shown, it is a top view of the automatic wafer box transmission system of the present invention, wherein the wafer box (i.e. material) is transported to each workstation 50 by the inner and outer loops to carry out related manufacturing process operations, and the inner loop is a conveyor belt 306, and the outer loop is an overhead transmission system 304. Figure 4 is along image 3 In the front view obtained by observing the line IV-IV, the overhead transport system (OHT) 304 includes a certain number of transport vehicles 301 for transmitting, receiving and placing FOUP wafer boxes 303 . The stretching arm 308 can be stretched to a predetermined position (such as Figure 4 The right half of ) to receive the FOUP wafer box 303 conveyed by the transfer vehicle 301 , the extending robot arm 308 has a fixed clamp 307 for clamping and fixing the FOUP wafer box 303 . The barcode reader 305 is used to read the barcode on the FOUP wafer box 303, so as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com