Luteolin metal salt and its preparation method and use

A technology of luteolin and metal salts, which is applied in the direction of pharmaceutical formulations, medical preparations containing active ingredients, respiratory diseases, etc., can solve the problems of low extraction rate of natural products, poor water solubility, and impact on application, and achieve prevention or treatment Hepatic fibrosis, easy operation, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0011] The specific steps of the preparation method of luteolin metal salt are as follows:

[0012] 1) Add 100 to 200 grams of rutin and 141 to 200 grams of sodium hydroxide in 3.5 to 4.5 liters of water in a 5L three-necked bottle, heat, reflux for 12 to 20 hours and cool to room temperature, and slowly add 500 to 600 ml of concentrated Hydrochloric acid to pH=1~4, suction filtration, obtain light yellow solid, solid product is joined in the water of 1000~1500 milliliters, is that 10~20% sodium hydroxide is adjusted pH=11~14 with weight percentage, filter cooling, use Adjust the pH to 1-4 with 10-20% hydrochloric acid by weight, filter, and dry the crude product at 80-100°C;

[0013] 2) Add the crude product to a 1:1 mixture of water and methanol, heat to dissolve, add 2 to 4 grams of activated carbon, reflux for 10 to 30 minutes, filter while it is hot, slowly cool the filtrate to room temperature, and keep it warm for 3 to 6 hours , filter, wash the filter cake with methan...

Embodiment 1

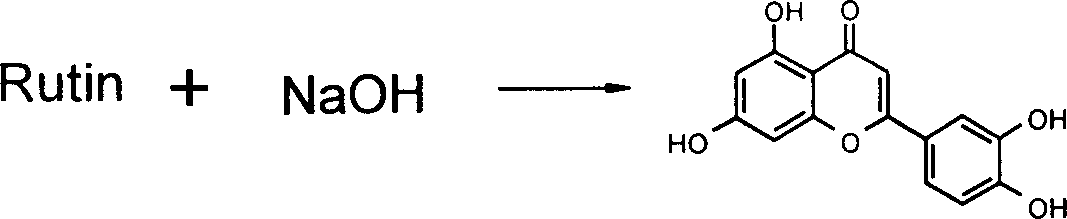

[0016] 1). Add 100 grams (0.164 moles) of rutin and 141 grams (3.53 moles) of sodium hydroxide to 4.5 liters of water in a 5-liter three-necked bottle, heat, reflux for 12 hours and cool to room temperature, then slowly add 560 milliliters of concentrated hydrochloric acid To pH = 1-4, filter with suction to obtain light yellow solid. The reaction formula is:

[0017]

[0018] The solid product was added to 1000 ml of water. Adjust pH=11-14 with 10% sodium hydroxide, filter and cool, adjust to pH=1-4 with 10% hydrochloric acid, and filter. After drying at 80°C, 41.0 g of crude product was obtained, and the calculated yield was 87.6%;

[0019] 2) Add 41.0 grams of crude product into a mixed solution of 123 grams of water and 123 grams of methanol, heat to dissolve, add 2 grams of gac, and reflux for 10 minutes. Filtrate while hot, slowly cool the filtrate to room temperature, keep warm for 3 hours, filter, wash the filter cake with methanol, and drain once. 26.7 grams of...

Embodiment 2

[0024] 1) Add 200 grams of rutin and 200 grams of sodium hydroxide to 4.5 liters of water in a 5-liter three-necked bottle, heat, reflux for 20 hours and cool to room temperature, slowly add 600 milliliters of concentrated hydrochloric acid to pH=4, and suction filter to obtain Light yellow solid, the solid product was added to 1500 ml of water, adjusted to pH=14 with 20% by weight sodium hydroxide, filtered and cooled, adjusted to pH=4 with 20% by weight of hydrochloric acid, filtered, and baked at 100°C Dried crude product;

[0025] 2) Add the crude product to a 1:1 mixture of water and methanol, heat to dissolve, add 4 grams of activated carbon, reflux for 30 minutes, filter while it is hot, slowly cool the filtrate to room temperature, keep it warm for 6 hours, filter, and wash with methanol The filter cake is drained once, dried and refined at 100°C;

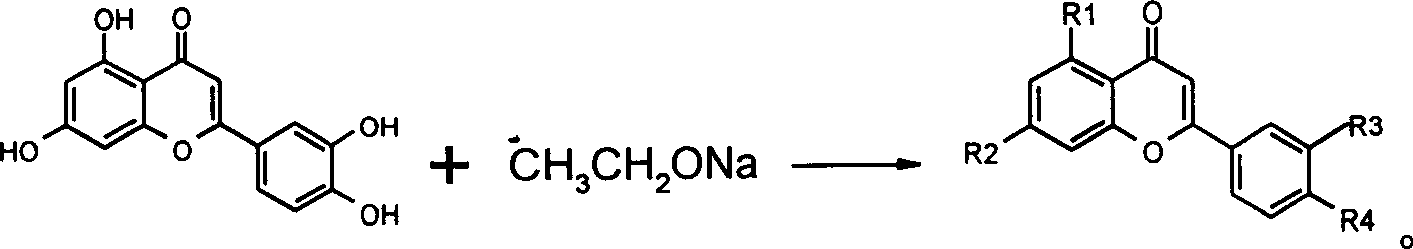

[0026] 3) Get 3 grams of sodium metal in 200 milliliters of absolute ethanol to make a sodium ethylate solution, put 15 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com