Production method of phenol formaldehyde resin used for normal temperature continuous casting and foaming and resin made by said method

A technology of phenolic resin and production method, which is applied in the production field of phenolic resin, can solve the problems of unsuitable normal temperature foaming process, high resin viscosity, and no phenolic resin has been seen yet, and achieve good cost-effectiveness ratio, economic and social benefits, The effect of reliable bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

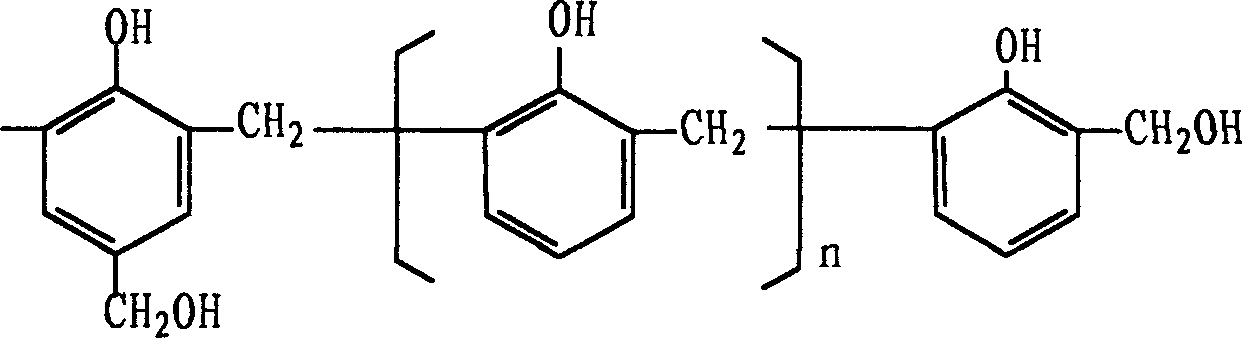

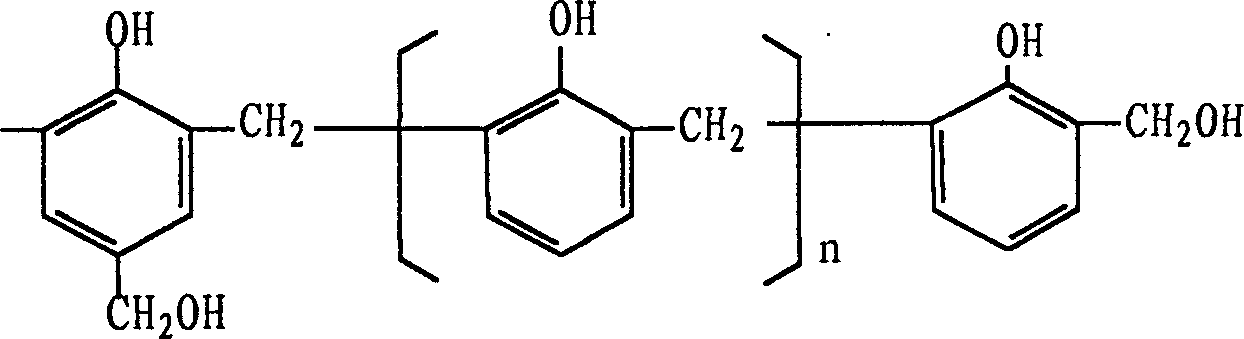

Image

Examples

Embodiment 1

[0050] Embodiment 1 (recipe 1)

[0051] Add 100 parts of phenol and 100 parts of formaldehyde into the reaction kettle with vacuum suction stirring, reflux, heating and cooling. After stirring for 15 minutes, add 5 parts of methanol, then slowly raise the temperature to 40°C under stirring, and maintain the reaction for 30 minutes. Add CaO 3 portion, and slowly heated up with stirring for about 50 minutes until the reaction boiled. React under boiling for 1.5 hours, add 10 parts of formaldehyde to continue the reaction, and when the gelling time reaches 110s at 150°C, make the system react under reduced pressure, adjust the vacuum degree and polycondensation reaction temperature (the maximum vacuum degree is 10Kpa, and the maximum temperature is 80°C ). When the solid content reaches the target requirement, cool down to below 40°C, add 1.6 parts of A1100 and absolute ethanol solution (1:1), 2 parts of Tween 80, 1 part of triethanolamine, and 3 parts of sili...

Embodiment 2

[0052] Embodiment 2 (recipe 2)

[0053] Operation according to Example 1, CaO in the formula is replaced by Ba(OH 2 ) and MgO composite system, 100 parts of phenol, 100 parts of formaldehyde, Ba(OH) 2 1 part, 1 part of MgO, 0.5 part of triethanolamine, 0.2 part of A1100. Synthesize phenolic resin according to example 1 operation.

Embodiment 3

[0054] Embodiment 3 (recipe 3)

[0055] Operation is by example 1, only changes the proportioning of phenol and formaldehyde, increases to 100 / 130 by the ratio 100 / 105 of phenol and formaldehyde among the embodiment 1, synthesizes phenolic resin by example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com