Casing. esp. for semiconductor device, foot of such semiconductor device and mfg. method of such foot

A technology for semiconductors and shells, applied in the field of semiconductor devices and manufacturing feet, which can solve problems such as decomposition and tearing, large mechanical tension, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

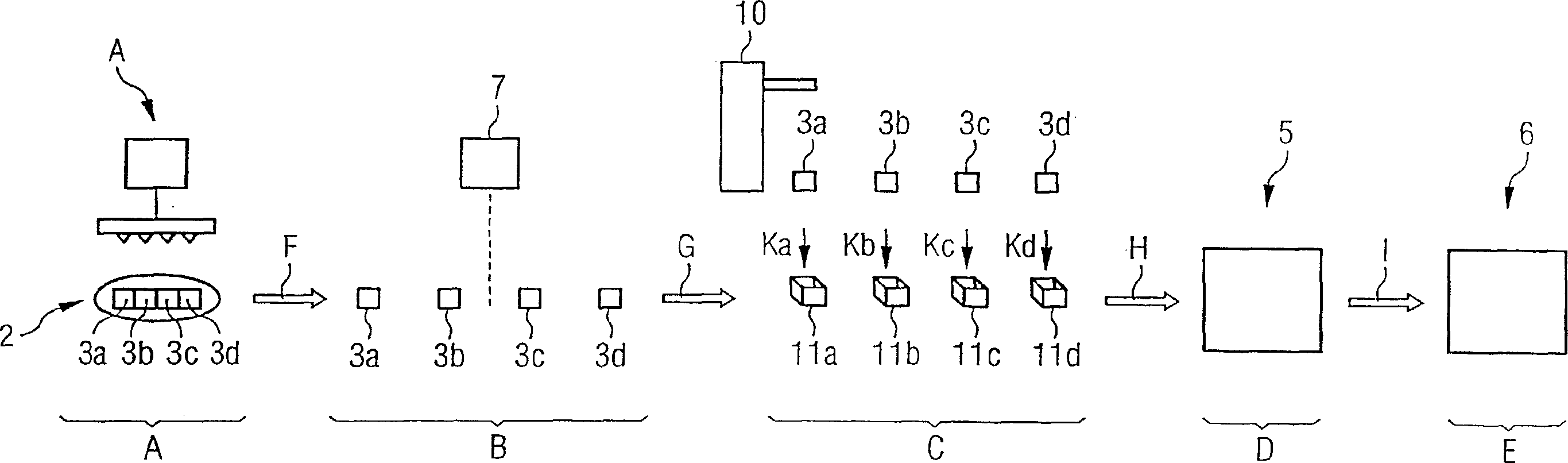

[0035] figure 1 Stations A, B, C, D through which some (absent a plurality of remaining stations, not shown) corresponding semiconductor devices 3a, 3b, 3c, 3d pass are schematically shown during manufacture of the semiconductor devices 3a, 3b, 3c, 3d.

[0036] At station A, semiconductor devices 3 a , 3 b , 3 c , 3 d are still available on a silicon disk or on a wafer 2 , respectively, subjected to one or a plurality of test methods by means of a test system 1 .

[0037] Prior to this, wafer 2 has, at a station not shown here and at figure 1 The previous stations A, B, C, D shown are subjected to the appropriate, conventional coating, exposure, etching, diffusion and implant processing steps.

[0038] The semiconductor devices 3a, 3b, 3c, 3d may, for example, be suitably integrated (analog or digital) electronic computing circuits, or semiconductor memory devices such as functional memory devices (PLAs, PALs, etc.) or desktop Type memory devices (such as ROMs or RAMs), such...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com