Driving circuit for display device

A technology of drive circuit and differential circuit, which is applied in the direction of electrical components, electronic switches, static indicators, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

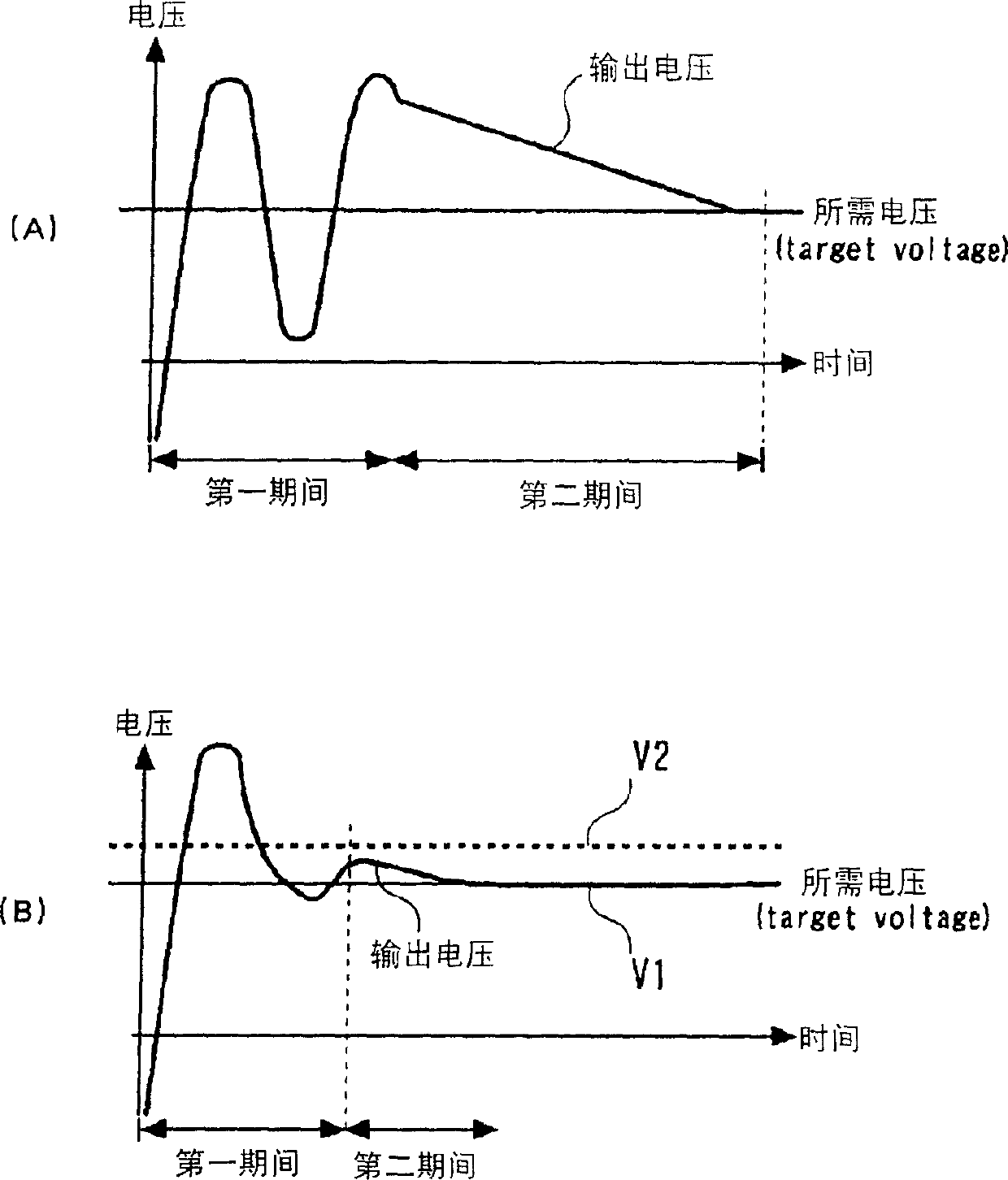

Problems solved by technology

Method used

Image

Examples

Embodiment

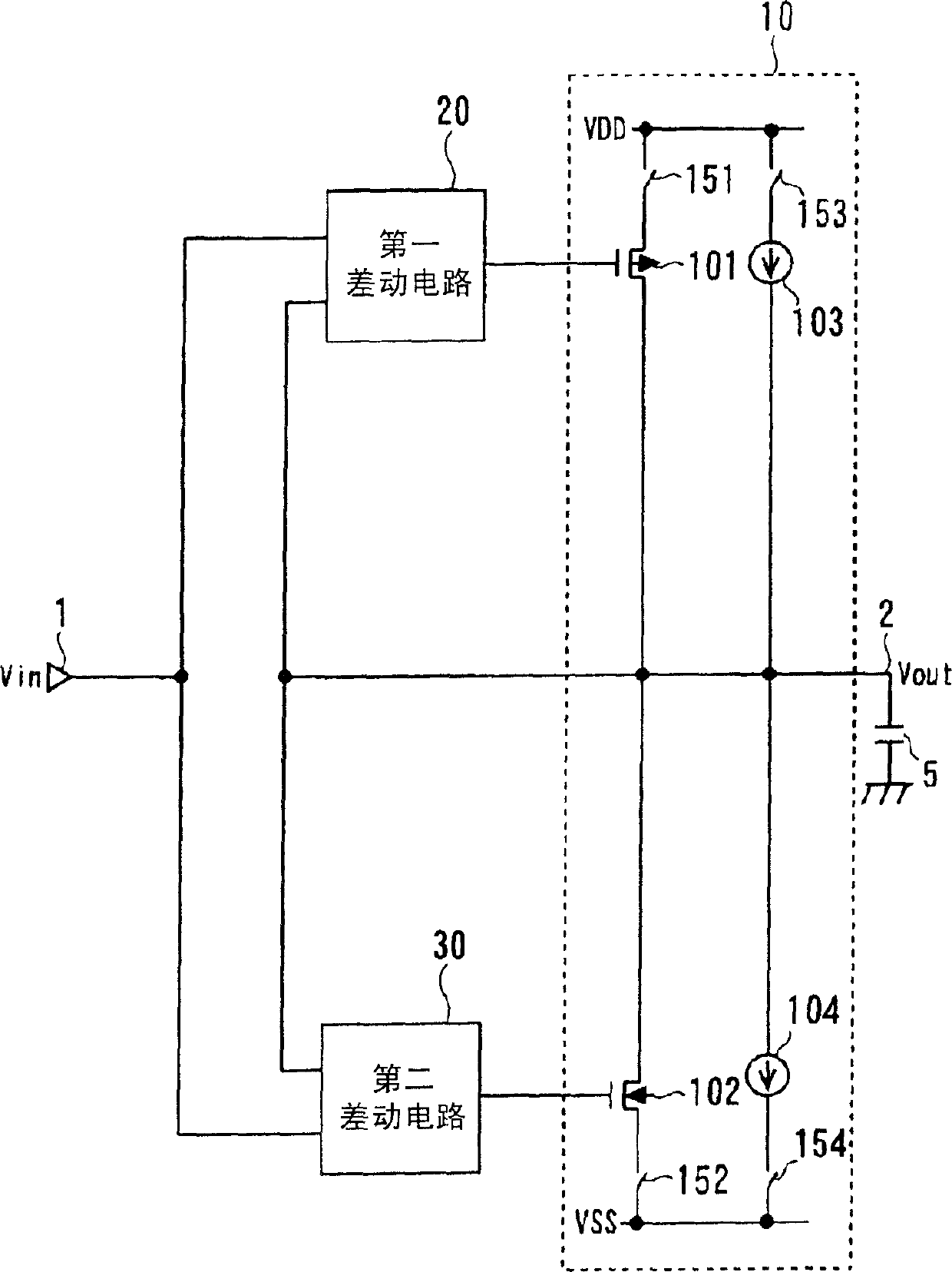

[0095] Embodiments of the present invention described above will be described in more detail, and embodiments of the present invention will be described here with reference to the accompanying drawings.

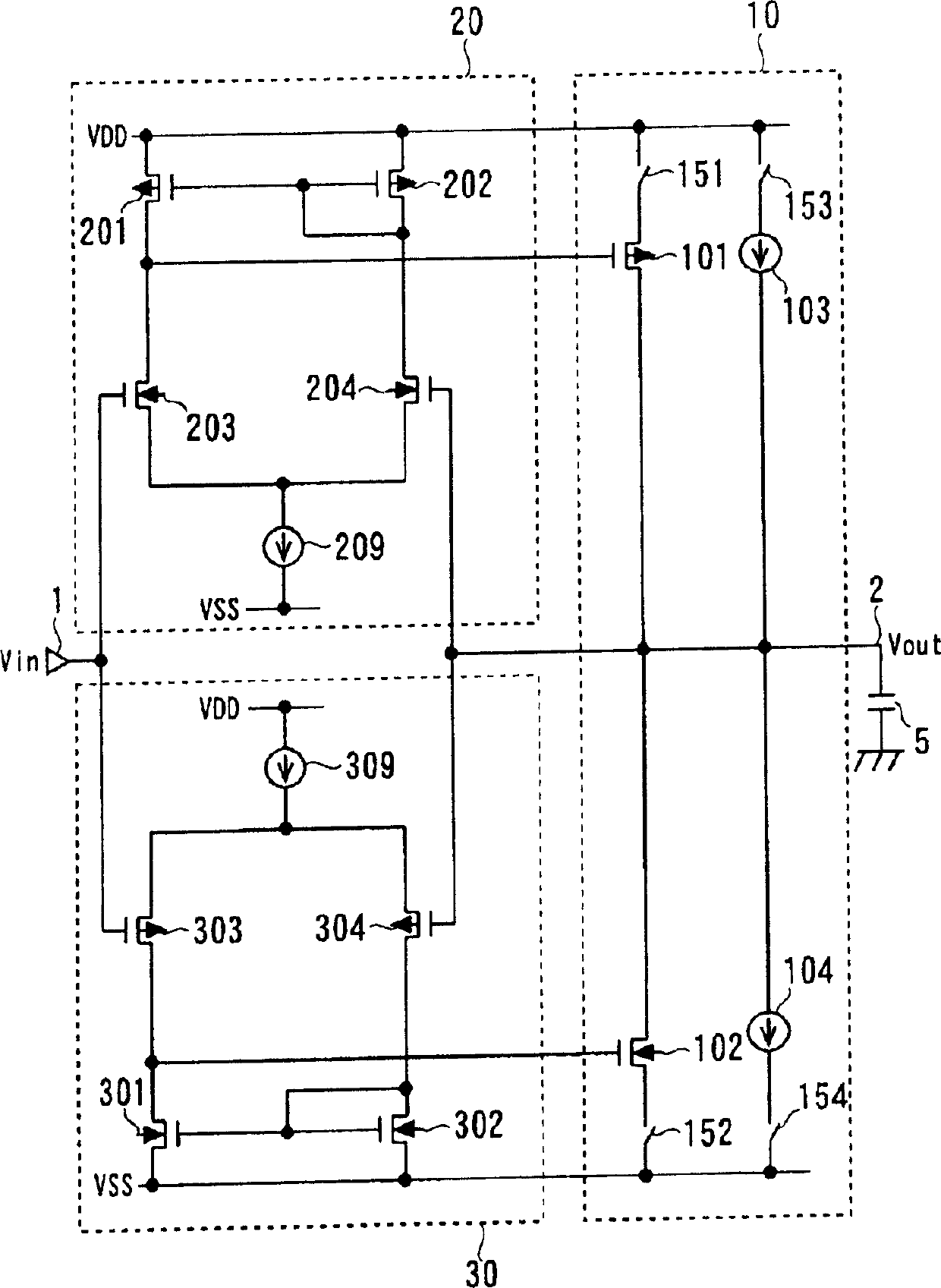

no. 1 example

[0097] 4 is a schematic diagram showing the configuration of the drive circuit according to the first embodiment of the present invention, and is a schematic diagram showing specific examples of the first differential circuit 20 and the second differential circuit 30 in the first drive circuit. Next, configurations of the first and second differential circuits 20 and 30 will be described. The first differential circuit 20 includes: n-channel differential pair transistors 203, 204 driven by a constant current source 209; Transistors 201, 202 form a current mirror circuit. More specifically, one end of the constant current source 209 is connected to the low-potential power supply VSS, and the other end is connected to interconnected sources of the n-channel transistors 203, 204 constituting a differential pair. The current mirror circuit is composed of p-channel transistors 201 and 202, each source of which is connected to the high potential power supply VDD, the p-channel tran...

no. 2 example

[0184]FIG. 7 shows the configuration of the drive circuit according to the second embodiment of the present invention, and shows an example of the configuration of the first and second differential circuits 20 and 30 of the drive circuit in FIG. 1 which is different from that in FIG. 4 . Next, configurations of the first and second differential circuits 20 and 30 will be described with reference to FIG. 7 . The structures of the first and second differential circuits 20, 30 on the inverting input side of the differential pair are different from those shown in FIG. 4 . Referring to Fig. 7, the first differential circuit 20 comprises n-channel differential pair transistors 203, 204, 205 driven by a constant current source 209; A current mirror circuit composed of p-channel transistors 201, 202. More specifically, one end of the constant current source 209 is connected to the low potential power supply VSS, and the other end is connected to the interconnected sources of the n-ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com