Process and device for aerating suspensions

一种悬浮液、液体的技术,应用在浮选、纺织品和造纸、回收利用技术等方向,能够解决降低印墨和污点去除的效率、增大纤维损失、污点难去除等问题,达到省去二次浮选、减少纤维的损失、改进污点的去除的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

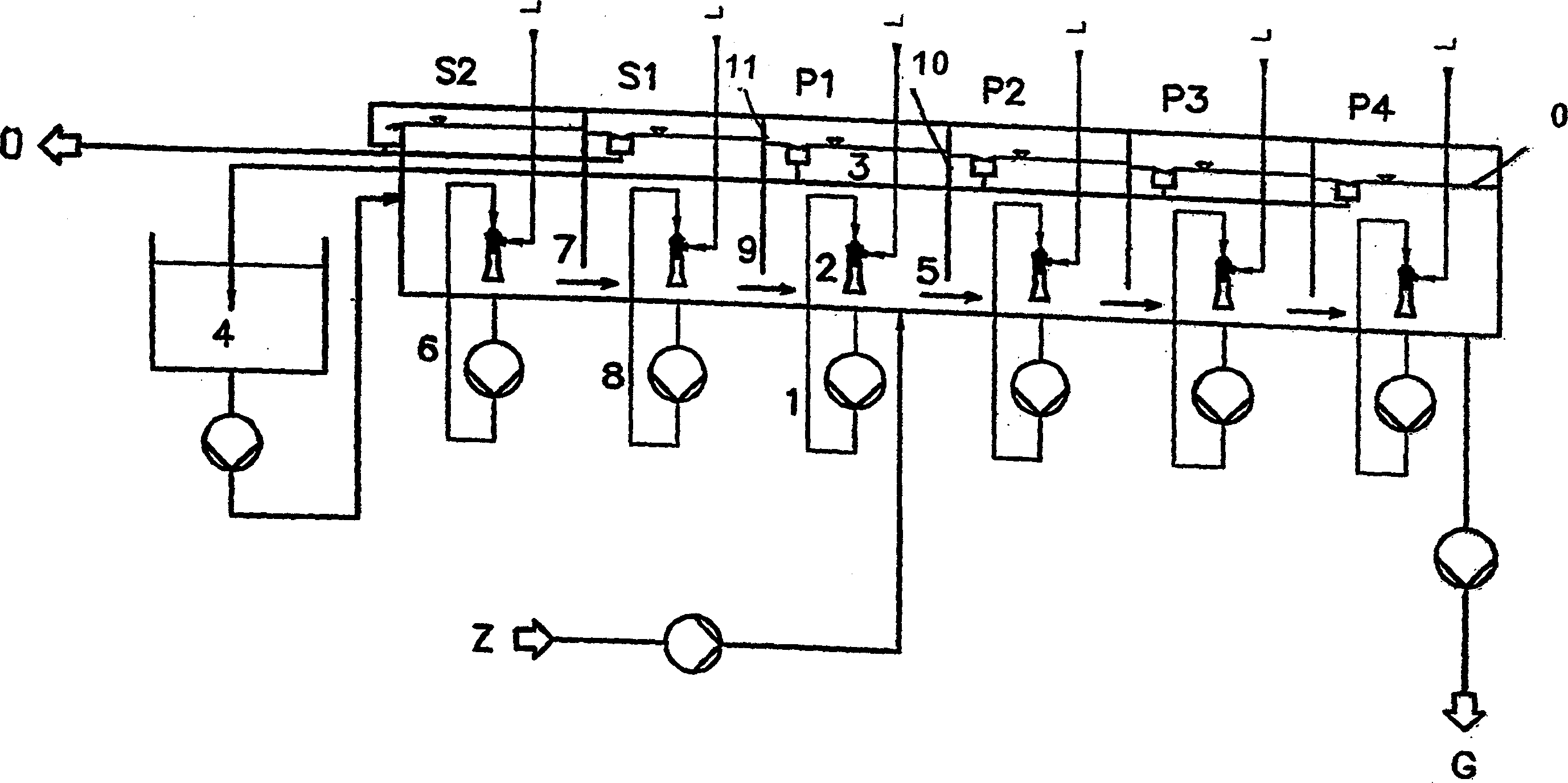

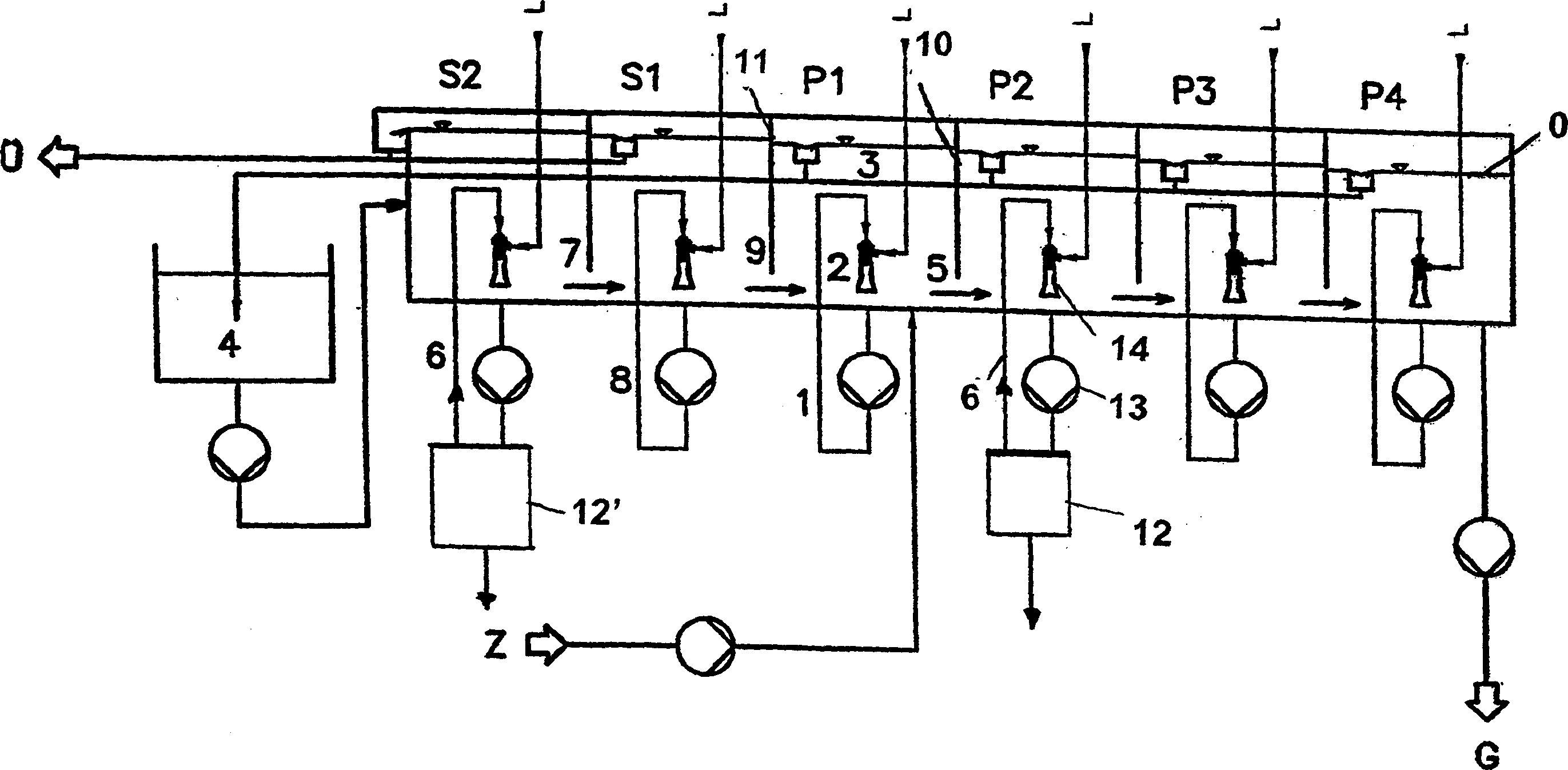

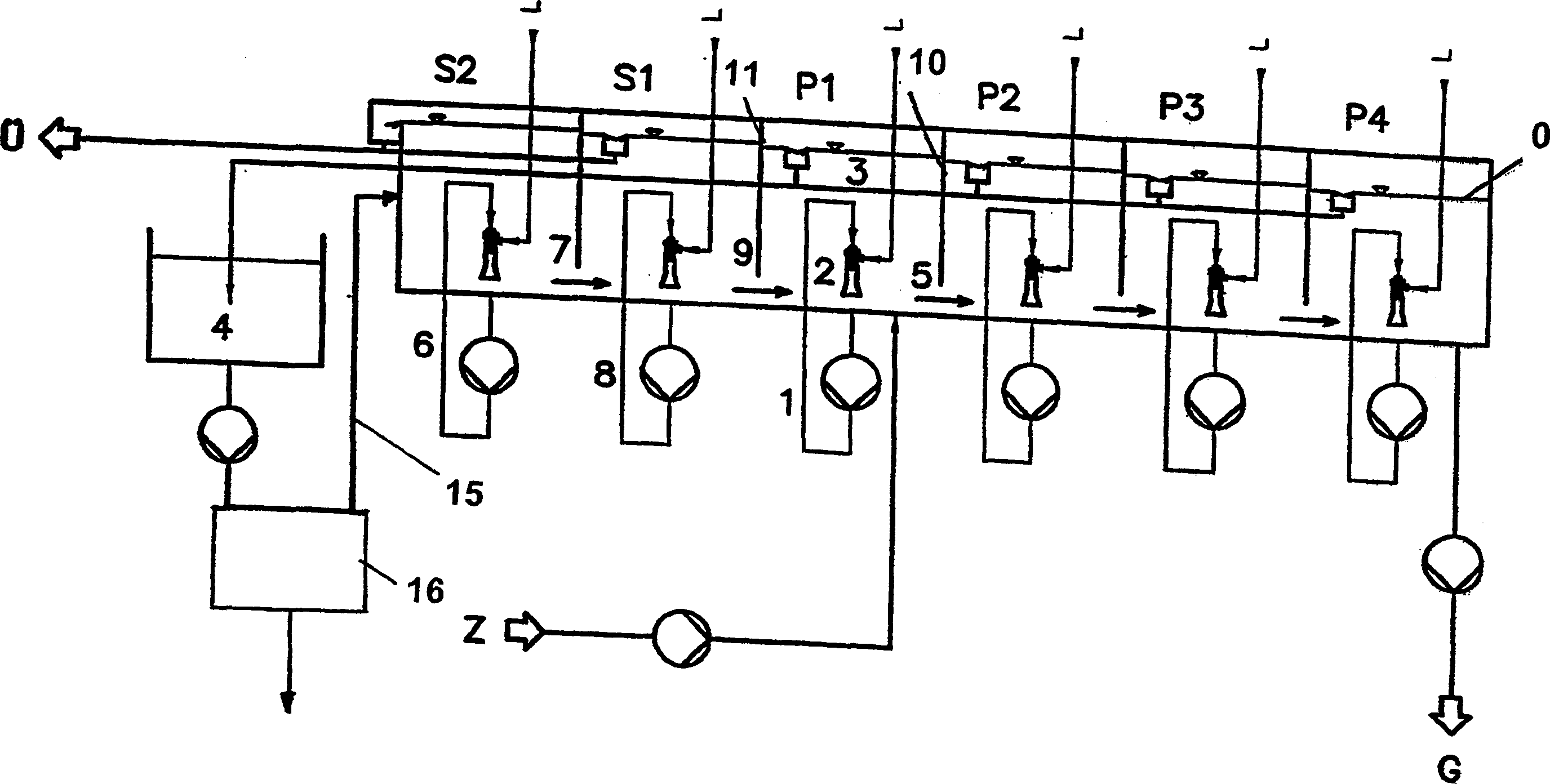

[0030] figure 1 It is a schematic diagram of a flotation device with four primary batteries P1, P2, P3, P4 and two secondary batteries S1, S2 in the prior art. The flow of slurry suspension Z enters the first galvanic cell P1 at a suitable point. Air bubbles are generated in the cell via circuit 1 , which is disconnected from the feed section, and air L is sucked in via injector 2 and mixed into the suspension. The entire flotation device is largely filled with a suspension whose surface 0 is formed with froth, containing as much material and ink particles as possible to be removed by flotation. The receiving stream filtered to remove ink and impurities in the primary cell P1 is conveyed through an opening 5 in the bottom of the partition wall 10 to the second primary cell P2. In all other galvanic cells at this time, the suspension was treated in the same way by means of bubble-generating injectors operated by the internal cell circuit and discharged as receiver G to the pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com