High-strength alloyed aluminum-system plated steel sheet and high-strength automotive part excellent in heat resistance and after-painting corrosion resistance

A corrosion-resistant, high-strength technology that is applied in the field of steel plates coated with an aluminum alloy system, which can solve problems such as delays in plating, increased stress, and scarring, and achieve excellent heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0049] The chemical composition of the steel sheet used in the present invention is explained below.

[0050] C: The steel sheet of the present invention has a high strength of not less than 1,000 MPa after forming, which is obtained by rapid cooling after high-temperature pressing and thereby transforming its structure into a structure mainly composed of martensite. In this sense, it is desirable that the C content is not less than 0.05%, and in order to stably obtain high strength, it is more desirable that the content is not less than 0.1%. On the other hand, even if the C content is increased to not less than 0.7%, its strength is saturated and weld cracks tend to occur, so it is limited to 0.7%.

[0051] Si: Since the Si content is too low to impair the fatigue properties, it is desirable to add it in an amount of not less than 0.05%. However, Si forms a stable oxide film on the steel sheet surface during recrystallization annealing and hinders the aluminum plating perfo...

Embodiment approach 2

[0065] The reason for adjusting the steel composition in Embodiment 2 of the present invention will be described below.

[0066] N is an element that is inevitably included and is specifically added when B is not added, however, when B is added and its amount is too large, it is necessary to increase the amount of Ti added. As a result, there are problems in that the amount of TiN finally produced increases and thermal cracks occur, and the cost also increases. Therefore, its upper limit is 0.1%.

[0067] B is added to improve the hardenability upon cooling during or after press molding, and in order to obtain this effect, its addition must be not less than 0.0002%. However, when its added amount is too large, there is a problem of thermal cracking and the effect is saturated. Therefore, its upper limit is 0.03%.

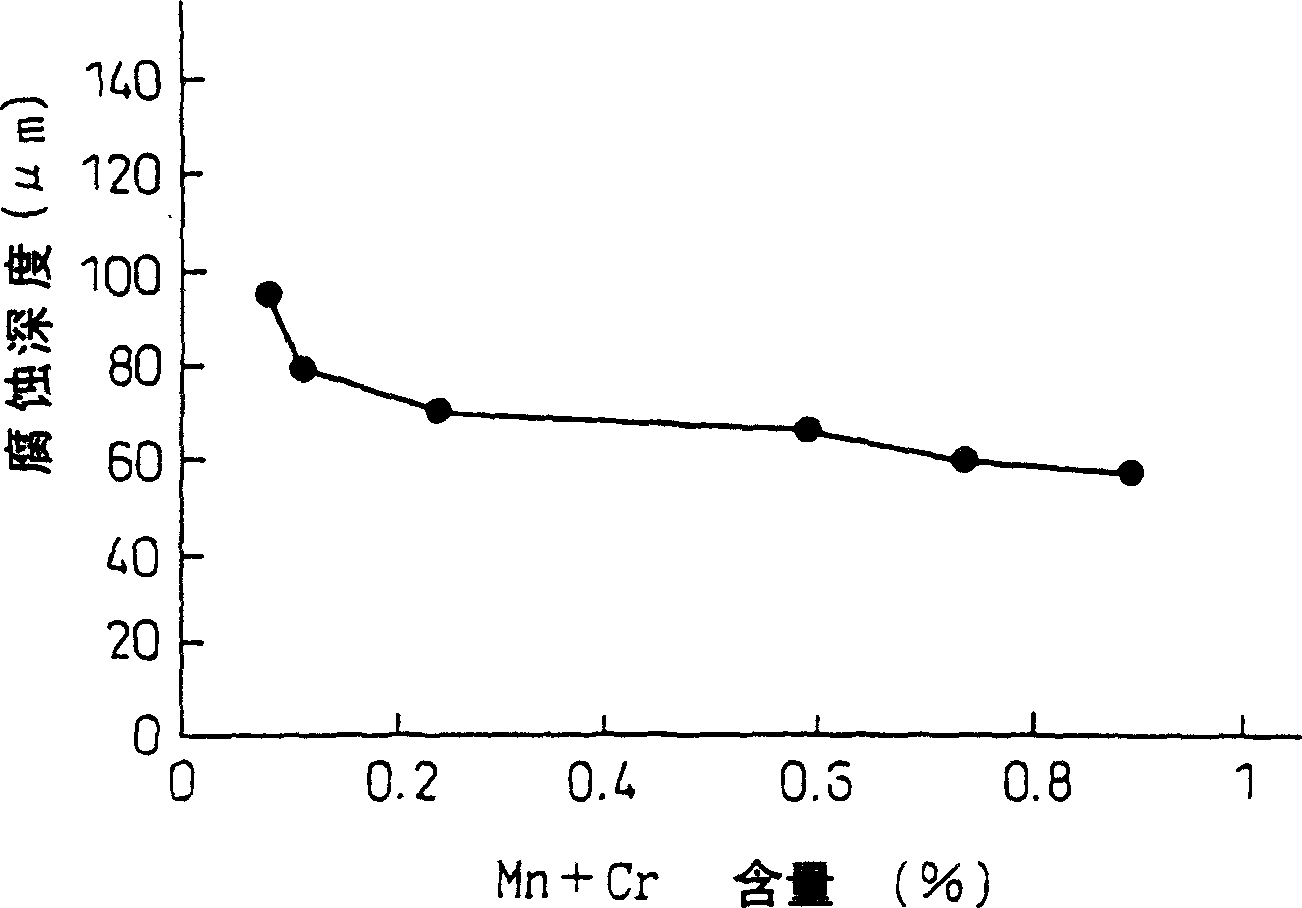

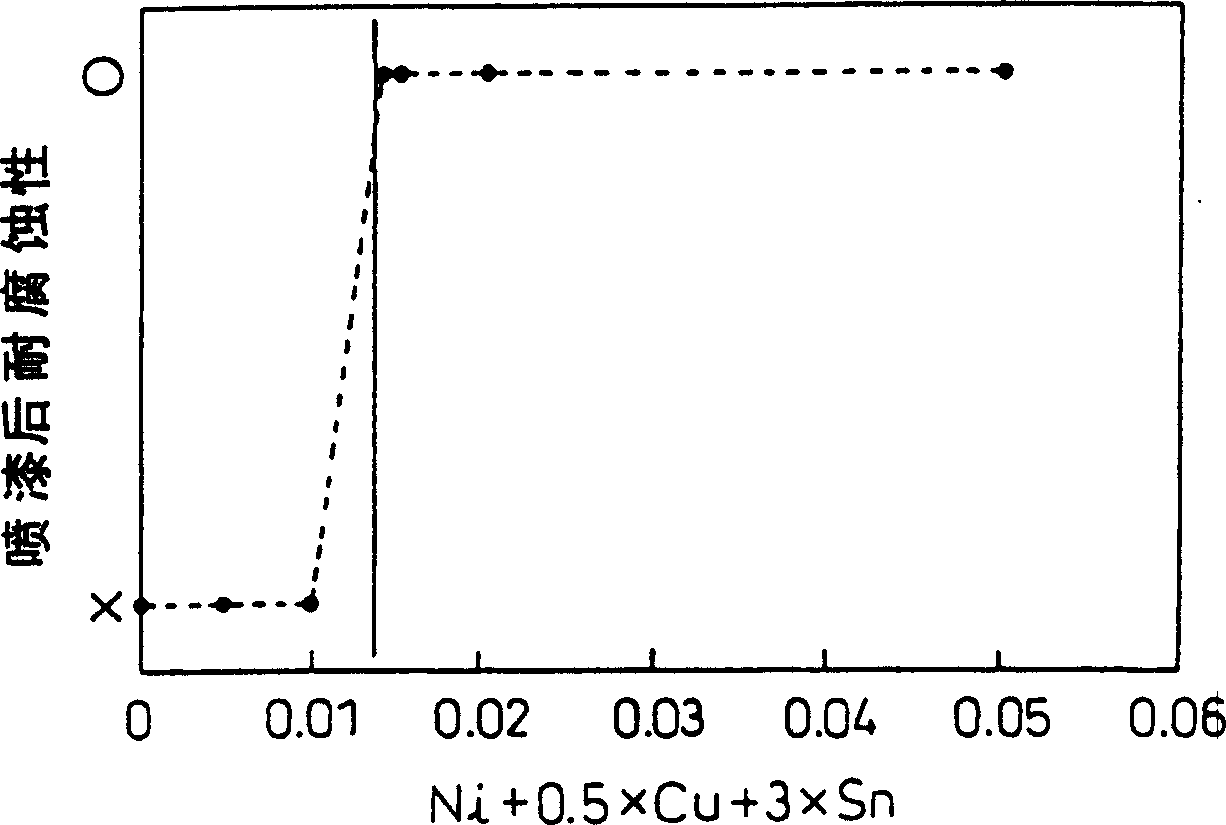

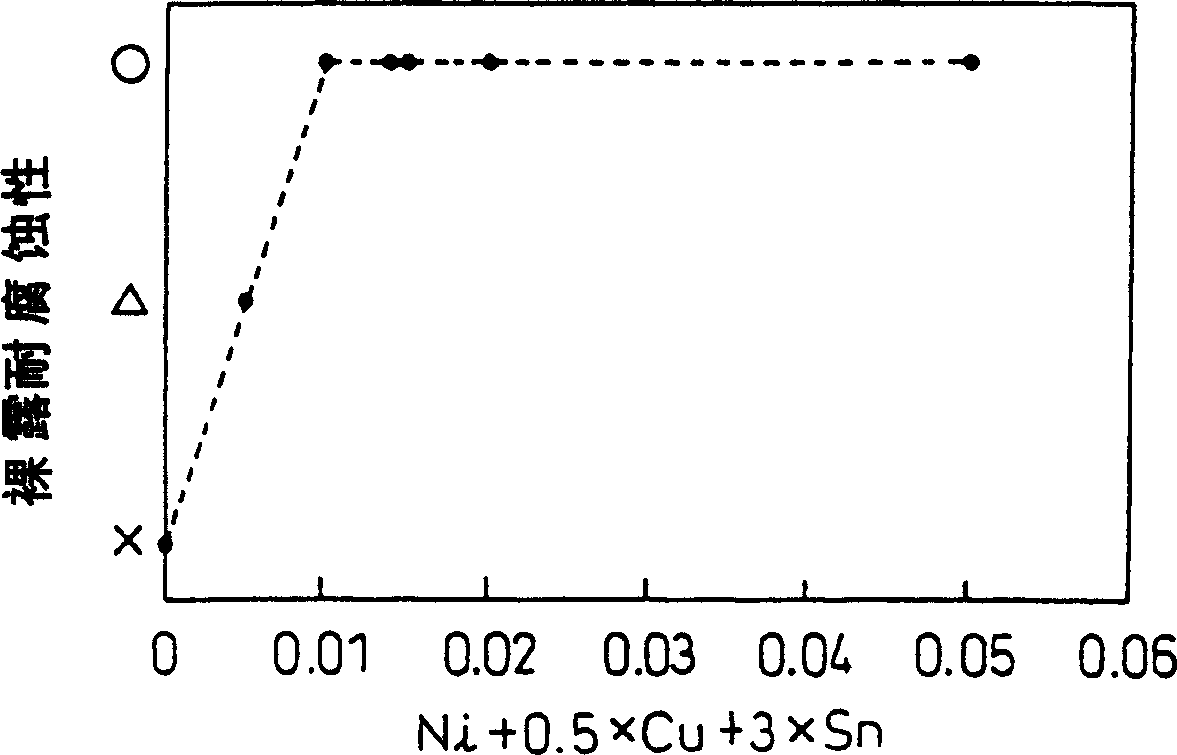

[0068] Ni, Cu, and Sn have an effect of changing the state of surface cracks during press-forming after high-temperature heating by changing the state of alloyed a...

Embodiment approach 3

[0080] First, the reason for adjusting the steel composition according to the present invention in Embodiment 3 will be explained below.

[0081] The addition of C element makes the structure after cooling consist of martensite, and ensures the quality of the material, and its addition amount is required to be not less than 0.15% to ensure that the strength is not lower than 1,200MPa. On the other hand, if the added amount is too large, the strength against impact deformation can hardly be ensured, so it is limited to 0.55%.

[0082] Si is a solute strengthening element and can increase the strength of steel sheets at relatively low cost. However, if it is added in excess, the plating performance will be impaired, so it is limited to 0.5% at its upper limit.

[0083] Mn is added to ensure post-cooling strength over a wide range of cooling rates.

[0084] When the amount of C is large but the amount of Mn added is small, the martensitic structure cannot be obtained within the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com