Hot-dip aluminium zinc alloy steel plate and its preparing process

A hot-dip aluminum and zinc alloy technology, applied in hot-dip plating process, metal material coating process, coating and other directions, can solve the problems of short service life of hot-dip galvanized steel sheet, embrittlement of metal substrate, poor safety performance, etc. Achieve the effect of preventing embrittlement, avoiding strain, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

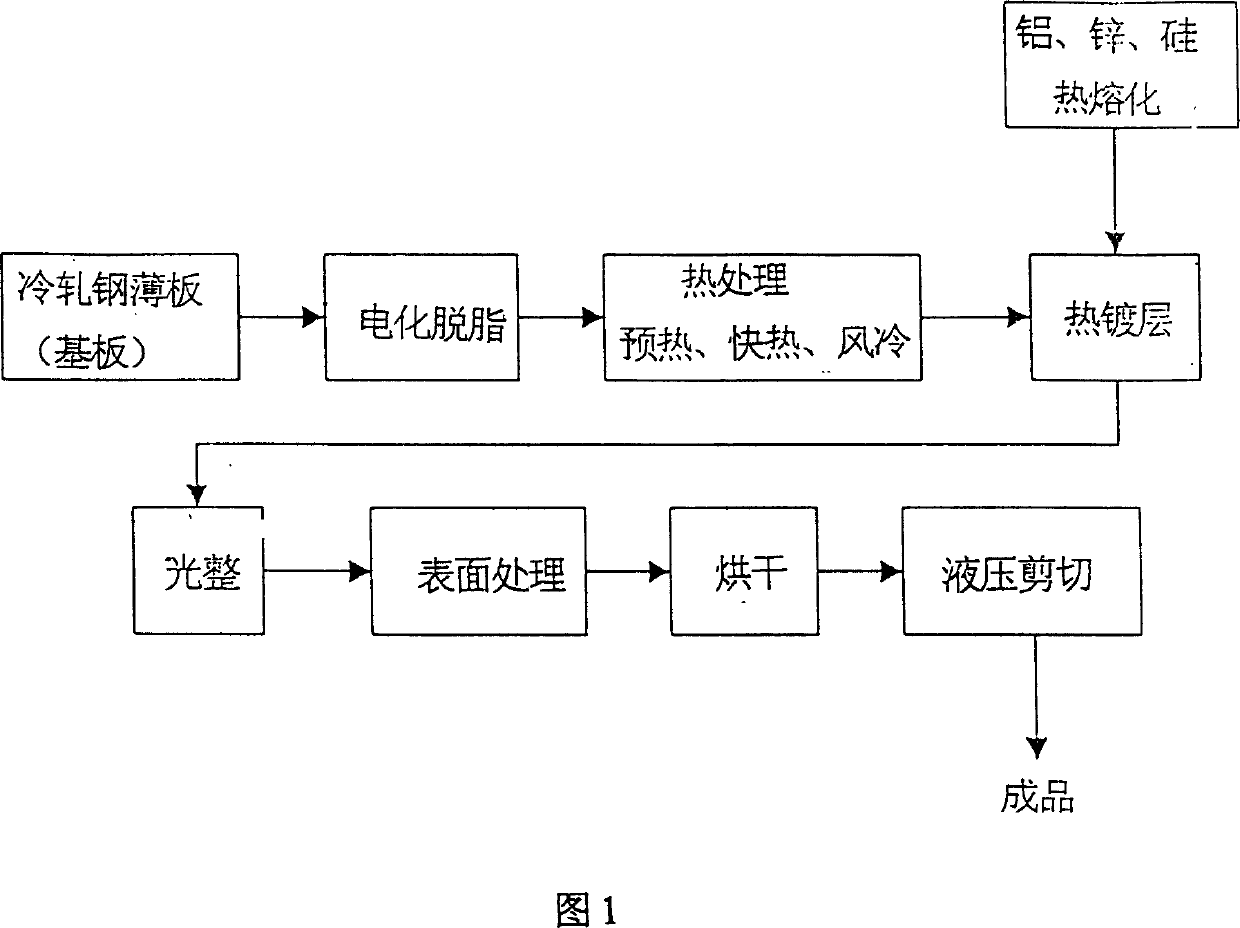

Method used

Image

Examples

Embodiment 1

[0029] The raw materials used in the embodiment of the present invention are all purchased from the market, and the equipment used are all conventional galvanizing units. The galvanizing unit includes an induction heating furnace, a solution degreasing tank, a continuous carbon furnace, a hot-dip coating unit, a skin pass machine, and a drying machine box.

[0030] Alloy production of the present invention: its composition ratio is calculated by weight percentage:

[0031] Take aluminum ingot 53, silicon 1.4, zinc ingot 45.6 and place it at 22.4m 3 Heating and melting in the induction heating furnace (pot), the induction heating furnace temperature is 680 ° C, uniform heating, melting time in the induction heating furnace is 15 days, and the solution temperature is 600 ° C for use.

[0032] The production process of the hot-dip aluminum-zinc alloy thin steel plate of the present invention is as follows: the cold-rolled steel plate is selected from SPCD, the width of the steel...

Embodiment 2

[0034] Alloy production of the present invention:

[0035] Take aluminum ingot 55, silicon 1.6, and the balance of zinc 43.4 and put it in a 22.4M3 induction heating furnace (pot) for melting. The temperature of the induction heating furnace is 680° C., and it is heated evenly. The melting time is 15 days, and the solution temperature is 550° C.

[0036] The production of hot-dip galvanized steel sheet of the present invention:

[0037] 1. Substrate steel selection: SPCD; steel coil width 1050mm thickness 0.20mm; electrochemical degreasing:; solution temperature: 60°C; solution weight percent concentration: 4%; electrochemical degreasing time (machine speed): 100-120 m / Minute;

[0038] 2. Heat treatment (preheating, rapid heating, rapid cooling, continuous annealing and reduction)

[0039] Preheating temperature: 400°C, preheating time (machine speed): 100-120 m / min;

[0040] Rapid heating temperature 730°C; rapid heating time (machine speed): 100-120m; rapid cooling (air ...

Embodiment 3

[0048] Embodiment three: the production of alloy of the present invention

[0049] Take aluminum ingot 56, zinc ingot 42.5, and silicon 1.5 and put them in a 22.4M3 induction heating furnace (pot) to melt, the temperature of the induction heating furnace is: 680°C, heat evenly, the melting time is: 15 days, and the solution temperature is: 600°C .

[0050] Product production of the present invention:

[0051] 1. Substrate steel selection: SPCD; steel coil width 1050mm, thickness 0.8mm; electrochemical degreasing: solution temperature: 70°C; solution weight percent concentration: 5%; electrochemical degreasing time (machine speed): 80-100 m / Minute

[0052] 2. Heat treatment (preheating, rapid heating, rapid cooling, continuous annealing and reduction)

[0053] Preheating temperature: 550°C, preheating time (machine speed): 80-100 m / min; rapid heating temperature 730°C; fast heating time (machine speed): 80-100 m / min; rapid cooling (air cooling): cooling Temperature: 600°C;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com