Heat reservoir of heat storage type heat pump air conditioning unit and preparation method for heat storage material thereof

A technology for heat pump air conditioners and heat storage materials, applied in heat pumps, heat storage equipment, indirect heat exchangers, etc. The effect of high heat transfer efficiency and high thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Use paraffin wax C 20 H 42 It is a phase change material with a phase change temperature of 40°C, a phase change latent heat of 186kJ / kg, and a thermal conductivity of 0.24W / m.K.

[0020] The acidified graphite is placed in a muffle furnace at a temperature of 800° C. and expanded for 20 seconds to prepare expanded graphite. Put 3g of the above phase change heat storage material and 7g of expanded graphite in an oven at 60°C for blending and adsorption for 1 hour, then filter and dry to prepare a paraffin / graphite composite phase change heat storage material. The phase change temperature of the paraffin wax / graphite composite phase change heat storage material is 45° C., the phase change latent heat is 56 kJ / kg, the thermal conductivity is 4.32 W / m.K, and the weight percentage Wt% of the paraffin wax is 30%.

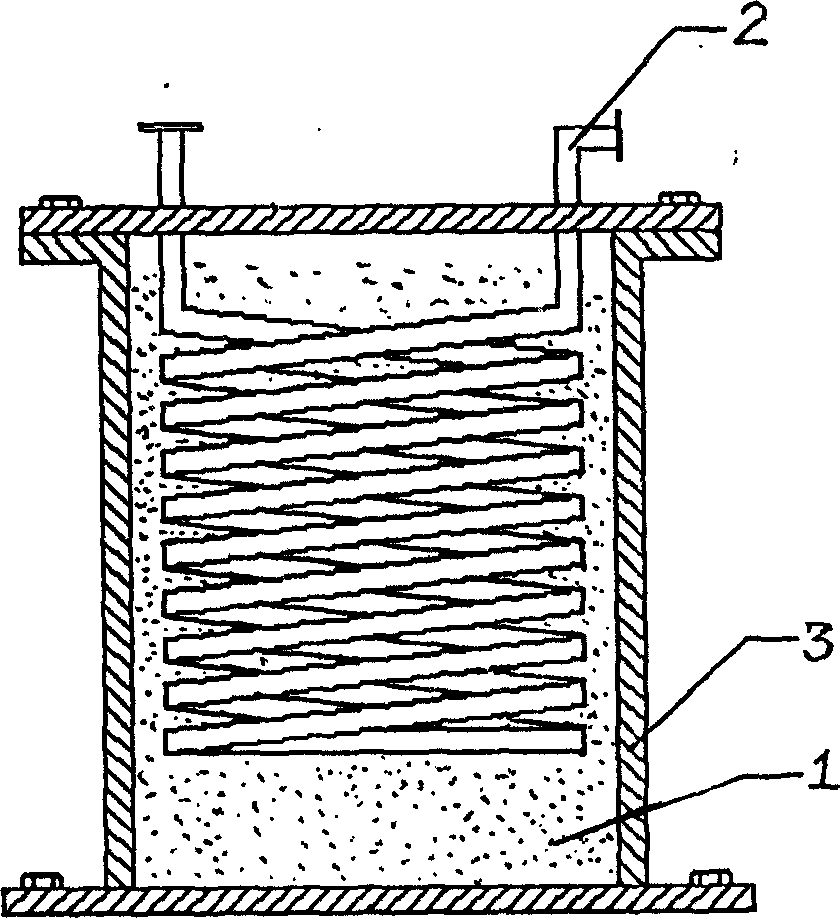

[0021] Use φ8×1mm smooth red copper tube to be processed into petal-shaped finned tube, coiled into a spiral coil heat exchanger structure with petal-shaped fin on th...

Embodiment 2

[0023] Use paraffin wax C 23 H 48 It is a phase change material with a phase change temperature of 45°C, a phase change latent heat of 192kJ / kg, and a thermal conductivity of 0.24W / m.K.

[0024] The acidified graphite is placed in a muffle furnace at a temperature of 900° C. and expanded for 30 seconds to prepare expanded graphite. 6g of the above phase change heat storage material and 4g of expanded graphite are placed in an oven at 60°C for blending and adsorption for 2 hours, then filtered and dried to prepare a paraffin / graphite composite phase change heat storage material. The phase change temperature of the paraffin wax / graphite composite phase change heat storage material is 45° C., the phase change latent heat is 115 kJ / kg, the thermal conductivity is 2.14 W / m.K, and the weight percentage Wt% of the paraffin wax is 60%.

[0025] Use φ8×1mm smooth red copper tube to be processed into petal-shaped finned tube, coiled into a spiral coil heat exchanger structure with petal-sha...

Embodiment 3

[0027] Use paraffin wax C 25 H 52 It is a phase change material with a phase change temperature of 50°C, a phase change latent heat of 200kJ / kg, and a thermal conductivity of 0.24W / m.K.

[0028] The acidified graphite is placed in a muffle furnace at a temperature of 1000° C. and expanded for 40 seconds to prepare expanded graphite. 9g of the above-mentioned phase change heat storage material and 1g of expanded graphite are placed in an oven at 60°C for blending and adsorption for 3.5 hours, then filtered and dried to prepare a paraffin / graphite composite phase change heat storage material. The phase change temperature of the paraffin / graphite composite phase change heat storage material is 45°C, the phase change latent heat is 180kJ / kg, the thermal conductivity is 1.02W / m.K, and the weight percentage Wt% of the paraffin wax is 90%.

[0029] Use φ8×1mm smooth red copper tube to be processed into petal-shaped finned tube, coiled into a spiral coil heat exchanger structure with peta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Latent heat of phase change | aaaaa | aaaaa |

| Latent heat of phase change | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com