Method of producing hydroxy free radical from reaction of ozone and exutad water

A technology of free radicals and excited states, applied in the direction of oxidized water/sewage treatment, etc., can solve the problems of increased transportation and storage costs, difficult application problems, high processing costs, etc., and achieve low operating costs, easy operation, and small equipment volume Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

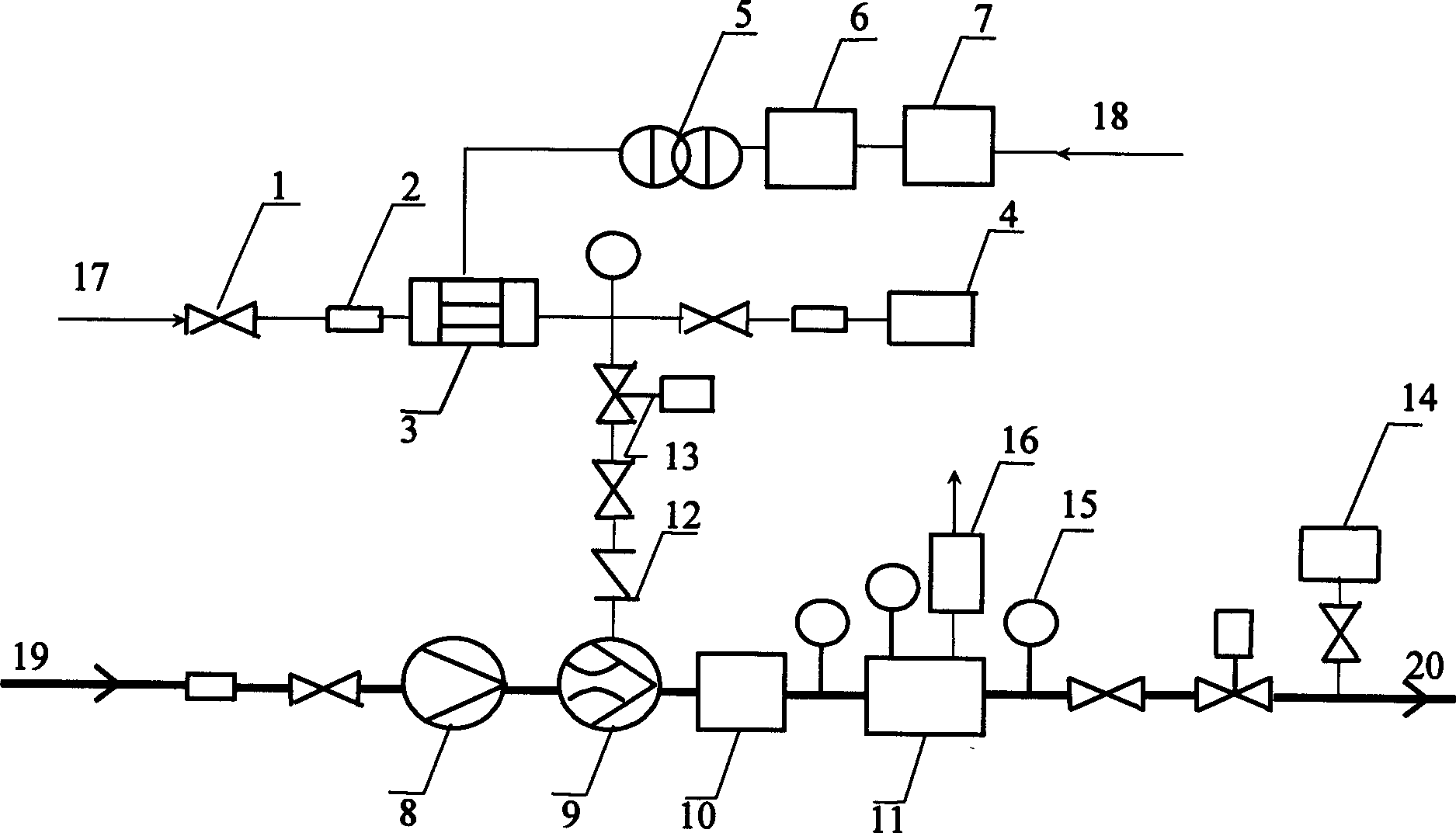

[0075] Oxygen gas 17 through figure 1 After the valve 1 and flowmeter 2 in the plasma generator 3, it is processed into O 3 , its concentration is as high as 400g / m 3 . o 3 Through the control of the electric valve 11 and the check valve 12, it reaches the Venturi ejector or the vortex impeller pump 9 . The pressure difference produced by the water 19 drawn in by the pump 8 at the front and rear ends of the Venturi ejector or the vortex impeller pump 9 is 0.4MPa to make the water in an excited state, which is different from O 3 The plasma chemical reaction is carried out, and then further dissolved by the gas-liquid dissolver 10 to generate a hydroxyl solution 20 with a specific concentration of 2-10 mg / L. The undissolved ozone is separated and removed with a gas-liquid separator 11 and a residual ozone processor 16 . figure 1 The high-frequency and high-voltage power supply composed of the middle transformer 5 , the inverter 6 and the controller 7 can convert the power f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com