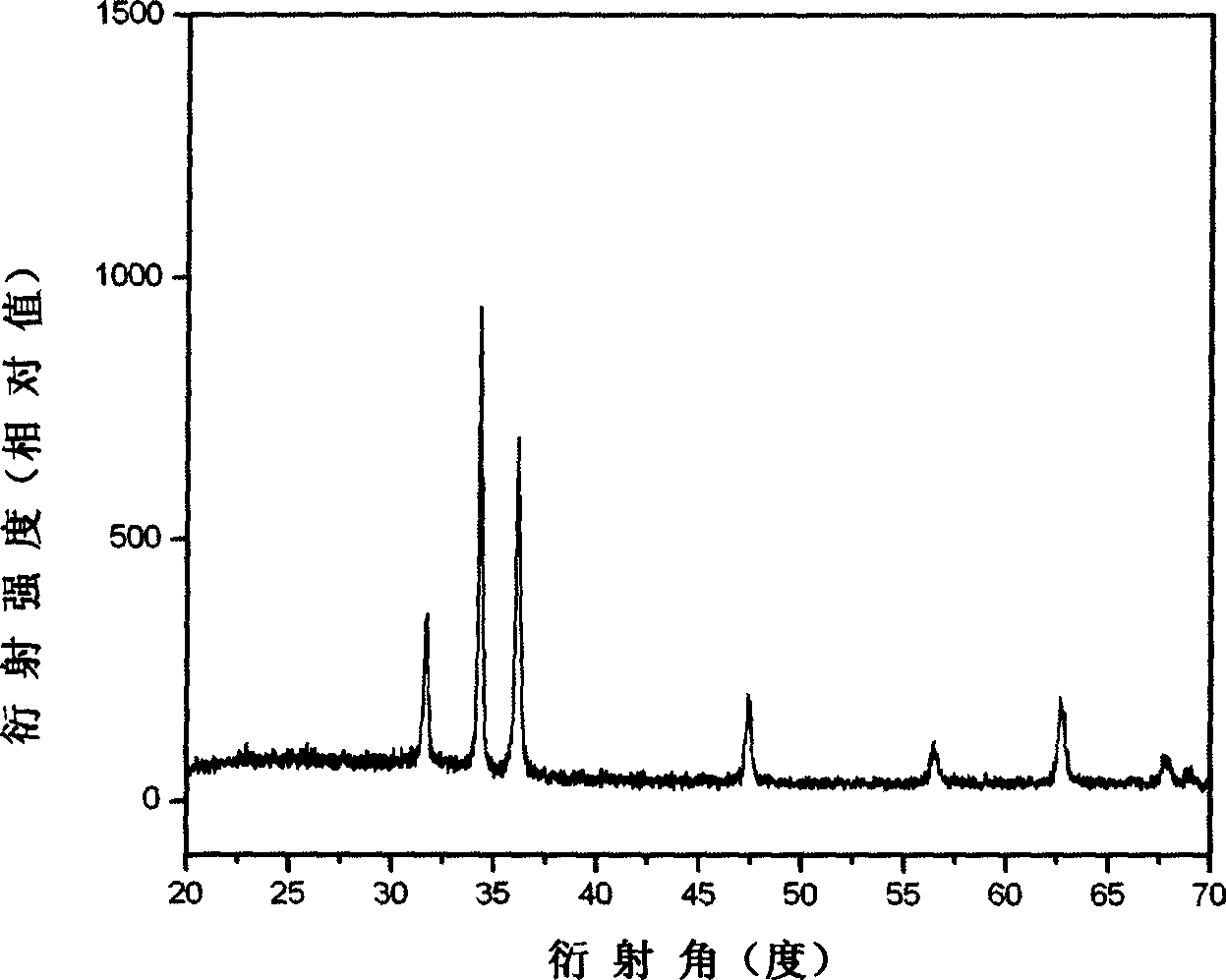

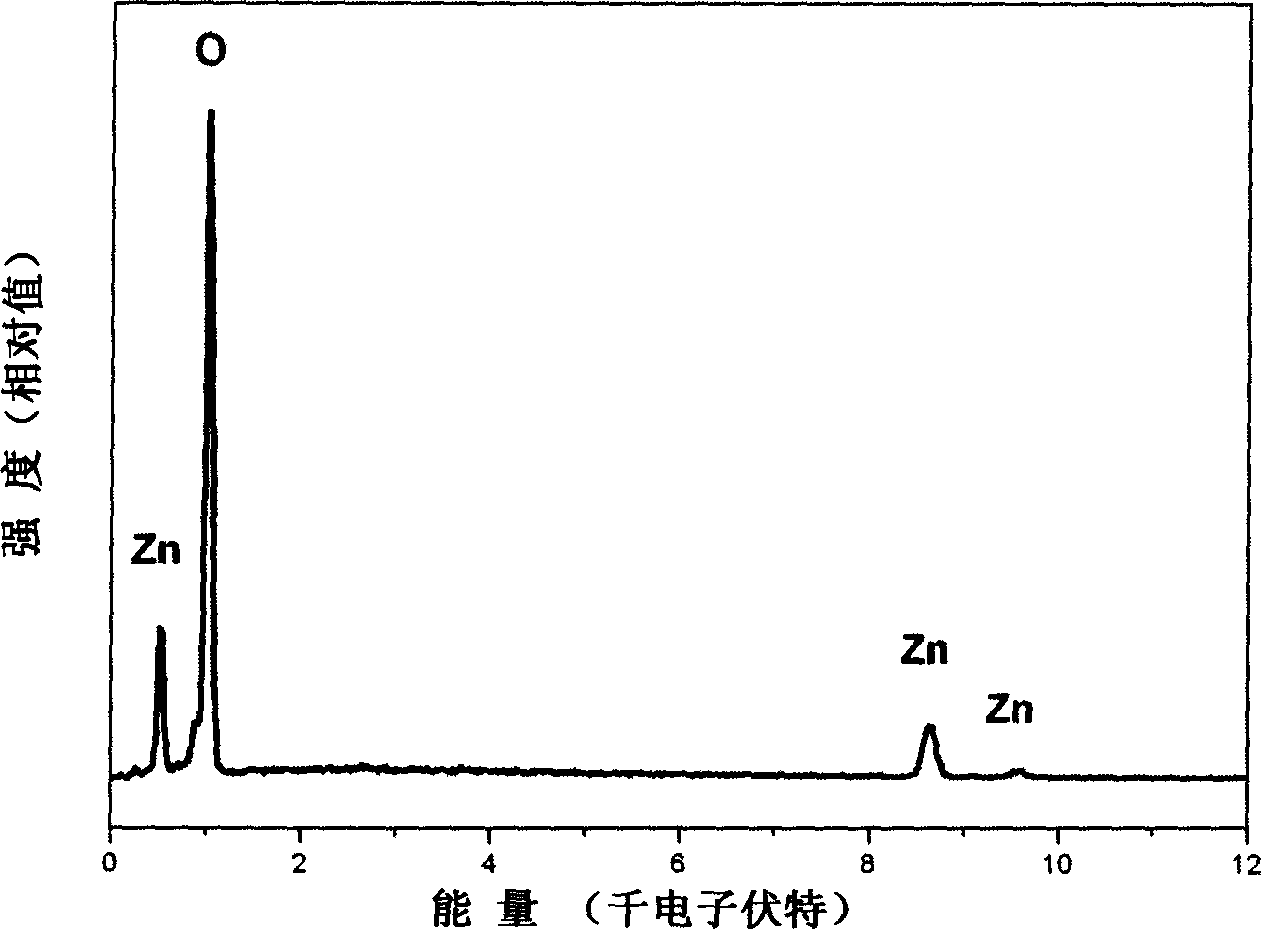

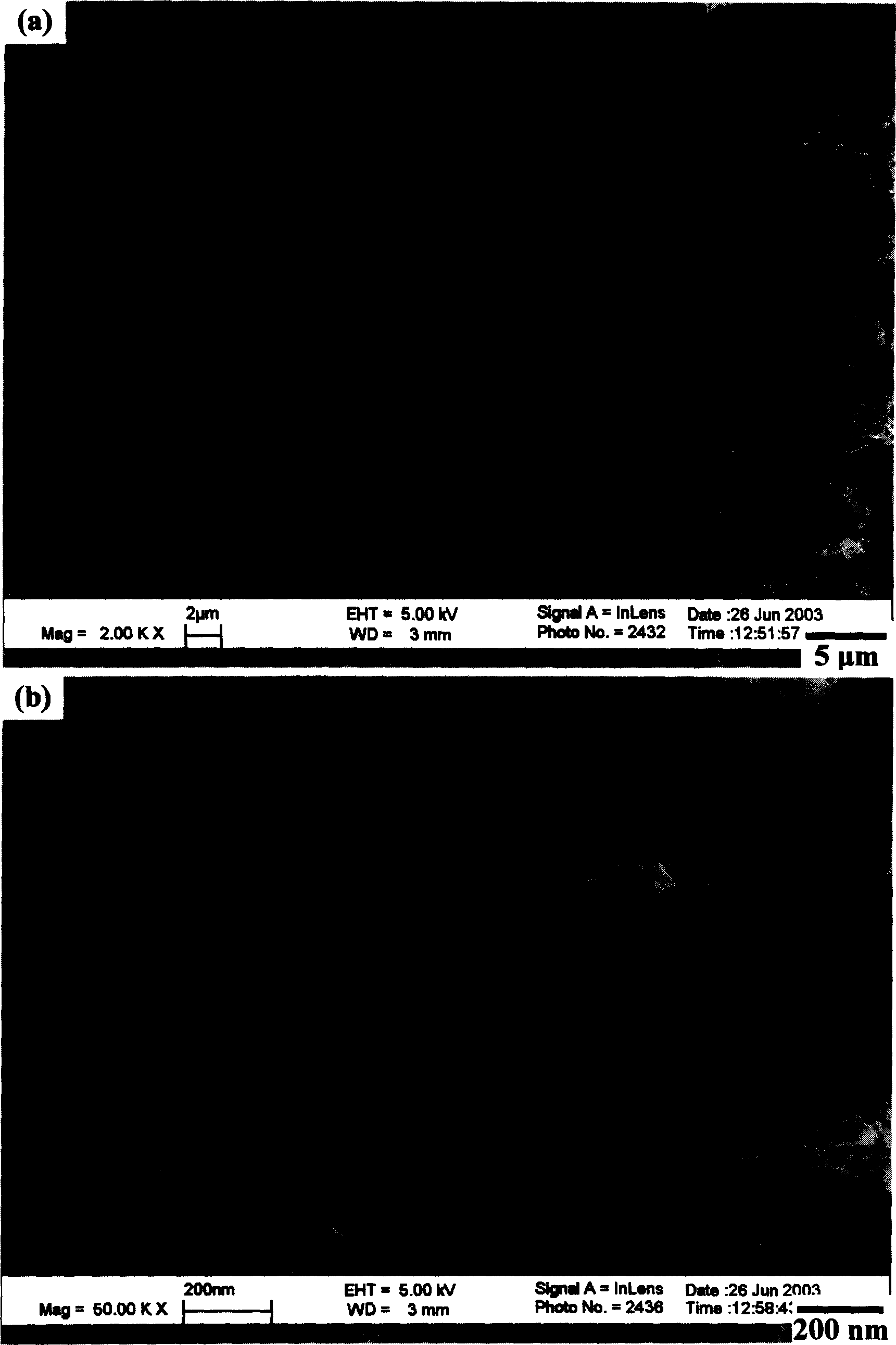

Method for preparing zinc oxide nanometer material with orientation arrangement nano-tubes

A zinc oxide nanometer and directional arrangement technology is applied in the field of preparation of zinc oxide nanomaterials, which can solve the problems of unfavorable cost and efficiency, influence, random dispersion, etc., and achieve the effects of low cost, high efficiency and good uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] ①In a 100mL tetrafluoroethylene plastic bottle, dissolve 0.01mol zinc nitrate, 0.01mol thiourea, and 0.002mol ammonium chloride in 95mL deionized water, stir until completely dissolved, then add 5ml of 25% ammonia water, while adding Stirring is continued, and after the solution is clarified, a reaction solution for growing a zinc oxide film is prepared.

[0020] ②Immerse a quartz plate with a length of 50mm and a width of 20mm into boiling concentrated sulfuric acid, soak it for 10 hours, then immerse it in acetone solution, ultrasonicate it for 30 minutes, rinse it with a large amount of deionized water, and finally put it in a vacuum oven to dry.

[0021] ③Immerse the quartz substrate treated according to step ② into the reaction solution prepared according to ①, ultrasonically for 35 minutes, then place the reaction bottle in an oil bath, and raise the reaction temperature to 95°C at a speed of 10°C / min , keep for 45 minutes. The quartz substrate is then immersed i...

Embodiment 2

[0024] ①In a 100mL tetrafluoroethylene plastic bottle, dissolve 0.01mol zinc nitrate, 0.01mol thiourea, and 0.002mol ammonium chloride in 95mL deionized water, stir until completely dissolved, then add 5ml of 25% ammonia water, while adding Stirring is continued, and after the solution is clarified, a reaction solution for growing a zinc oxide film is prepared.

[0025] ②Immerse a glass piece with a length of 50mm and a width of 20mm into boiling concentrated sulfuric acid, soak it for 10 hours, then immerse it in acetone solution, ultrasonicate it for 60 minutes, rinse it with a large amount of deionized water, and finally put it in a vacuum oven to dry.

[0026] ③Immerse the glass substrate treated according to step ② into the reaction solution prepared according to ①, ultrasonicate for 40 minutes, then place the reaction bottle in an oil bath, and raise the reaction temperature to 97°C at a speed of 20°C / min , keep for 50 minutes. The glass substrate is then cooled by imme...

Embodiment 3

[0028] ①In a 100mL tetrafluoroethylene plastic bottle, dissolve 0.01mol zinc nitrate, 0.01mol thiourea, and 0.002mol ammonium chloride in 95mL of deionized water, stir until completely dissolved, then add 5ml of 25% ammonia water, while adding Stirring is continued, and after the solution is clarified, it is prepared as a reaction solution for growing zinc oxide nanomaterials with aligned nanotubes.

[0029] ②Immerse a quartz plate with a length of 50mm and a width of 20mm into boiling concentrated sulfuric acid, soak it for 8 hours, then immerse it in acetone solution, ultrasonicate it for 45 minutes, rinse it with a large amount of deionized water, and finally put it in a vacuum oven to dry.

[0030] ③Immerse the quartz substrate treated according to step ② into the reaction solution prepared according to ①, ultrasonicate for 38 minutes, then place the reaction bottle in an oil bath, and raise the reaction temperature to 94°C at a speed of 15°C / min , keep for 60 minutes. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com