Micropattern forming material and fine structure forming method

A micro-pattern and micro-structure technology, which is applied in photosensitive material processing, photoplate-making process on patterned surface, photosensitive material used in photomechanical equipment, etc., can solve the problem of low reactivity, deformation of first resist pattern, formation Membrane reduction and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

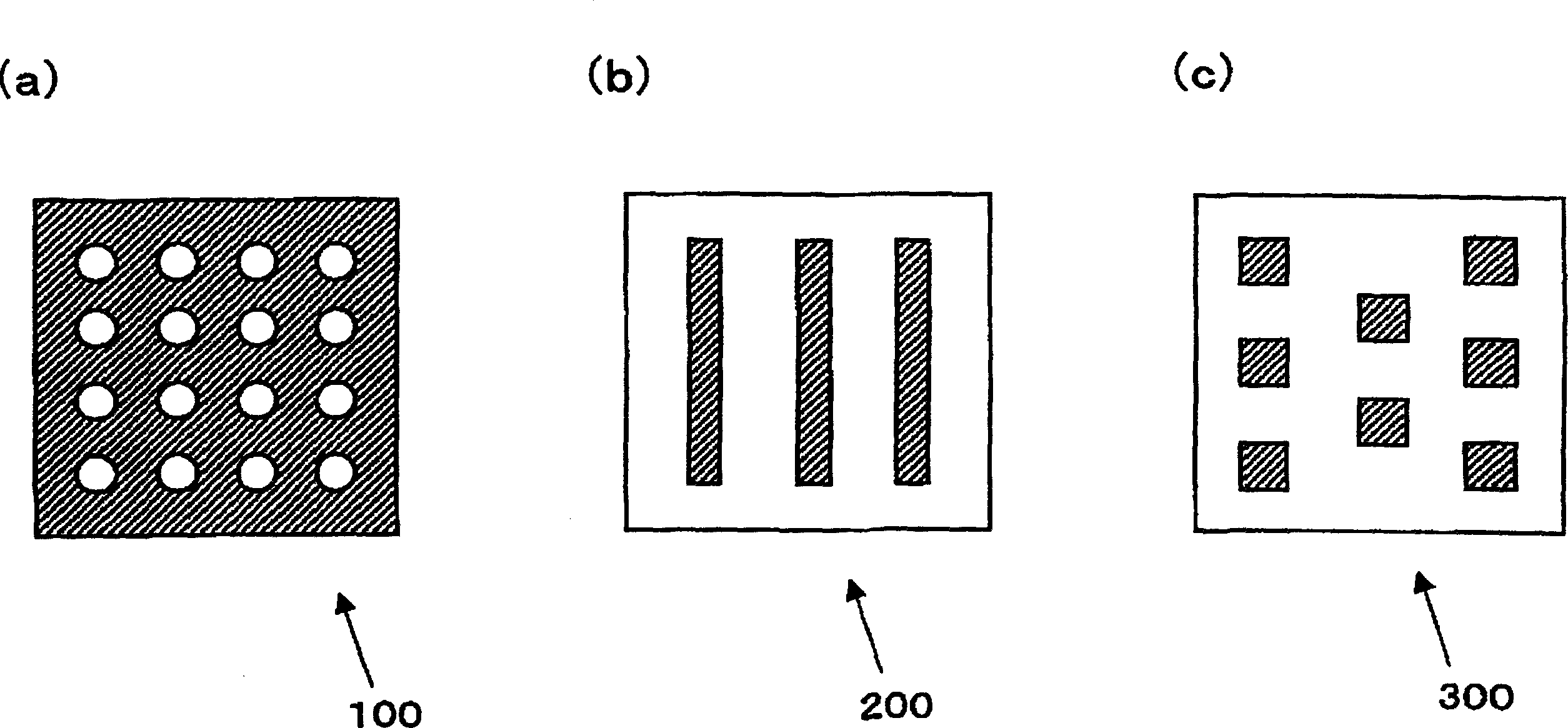

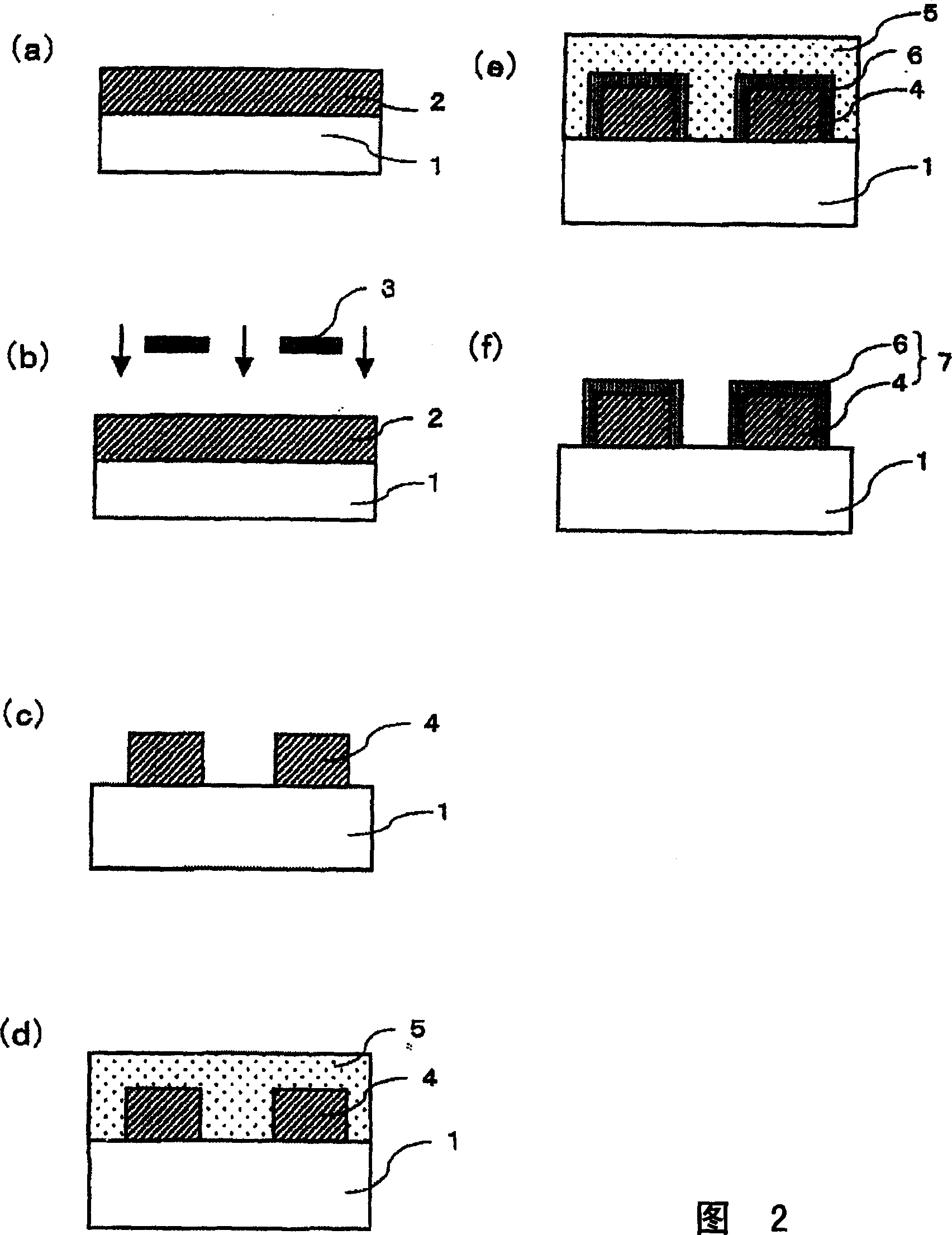

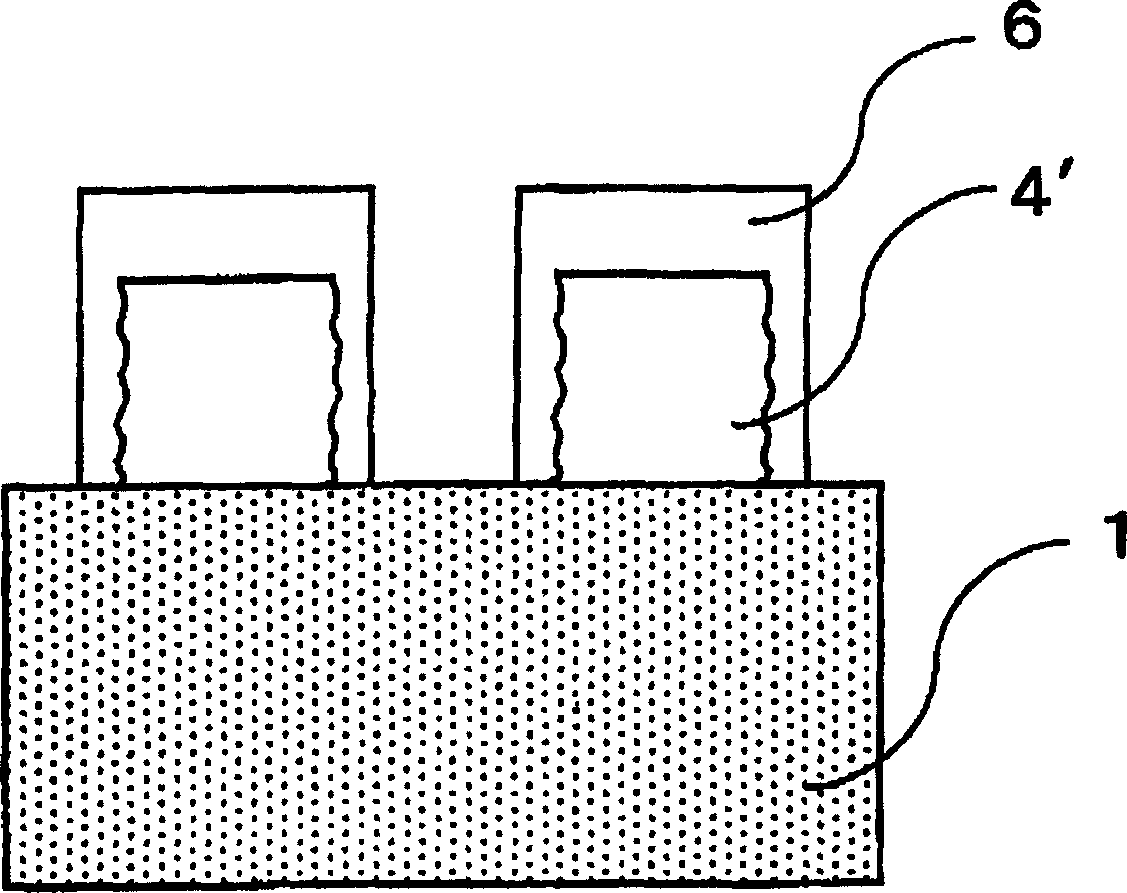

[0044] figure 1 It is a diagram showing an example of a mask pattern for forming a resist pattern finely divided as a target in the present invention. figure 1 (a) is a masking pattern 100 of fine holes, figure 1 (b) is a mask pattern 200 at fine intervals, figure 1 (c) is the pattern 300 left in isolation. In the figure, for example, hatched portions indicate resist-formed portions. In addition, FIG. 2 is a process diagram showing an example of the semiconductor device manufacturing method according to the present embodiment.

[0045] First, as shown in FIG. 2( a ), a resist composition is applied on a semiconductor substrate 1 to form a resist film 2 . For example, a resist composition having a film thickness of about 0.7 μm to 1.0 μm is applied on a semiconductor substrate by using a spin coating method or the like.

[0046] In this embodiment, as a resist composition, a resist that generates an acid component inside the resist by heating is used. Examples of the resi...

Embodiment approach 2

[0141] In this embodiment, it is characterized in that exposure is performed before the MB processing described in Embodiment 1.

[0142] Figure 4 is a process diagram showing an example of a method of manufacturing a semiconductor device according to this embodiment. Figure 4 (a)-(d) are carried out according to the same process as Fig. 2(a)-(d). That is, after the resist composition is coated on the semiconductor substrate 8 to form the resist film 9, exposure is performed through the mask 10 to form the resist pattern 11. Here, as the resist composition in this embodiment, a chemically amplified resist that generates oxygen by exposure can be used.

[0143] Then, form as Figure 4 After forming the film 12 with the fine pattern shown in (d), as Figure 4 As shown in (e), the entire surface of the semiconductor substrate 8 is exposed using g-rays or i-rays from a mercury lamp. Thereby, instead of the MB treatment or before the MB treatment, acid can be generated in th...

Embodiment approach 3

[0157] In this embodiment mode, it is characterized in that only a desired region of the semiconductor substrate is exposed after forming a resist pattern.

[0158] Figure 5 is a process diagram showing an example of a method of manufacturing a semiconductor device according to this embodiment. Figure 5 (a)-(d) are carried out according to the same process as Fig. 2(a)-(d). That is, after the resist composition is coated on the semiconductor substrate 15 to form the resist film 16, exposure is performed through the mask 17 to form the resist pattern 18. Here, as the resist composition in this embodiment, a chemically amplified resist that generates acid by exposure can be used.

[0159] Then, form as Figure 5 (d) After forming the film 20 with a fine pattern shown in (d), to Figure 5 As shown in (e), the resist pattern is selectively exposed using a suitable light shield 19 . For exposure, for example, g-rays or i-rays from a mercury lamp can be used. Thus, acid can ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com