Sealed basic Ni-Cd secondary cell

A secondary battery, alkaline technology, used in alkaline storage batteries, alkaline storage battery electrodes, battery electrodes, etc., can solve the problems of unsafe batteries, long duration, high internal pressure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

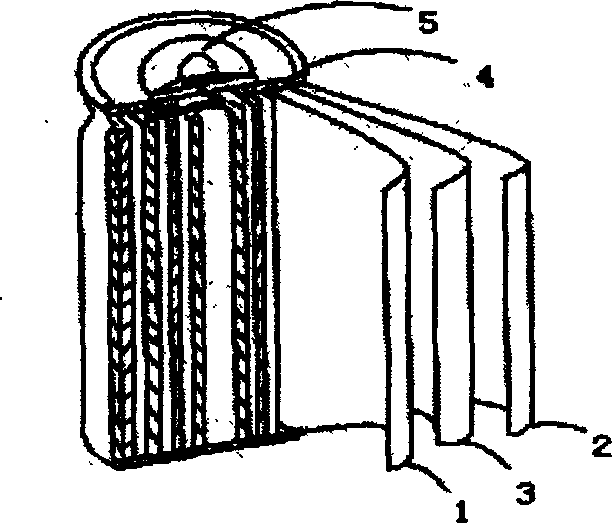

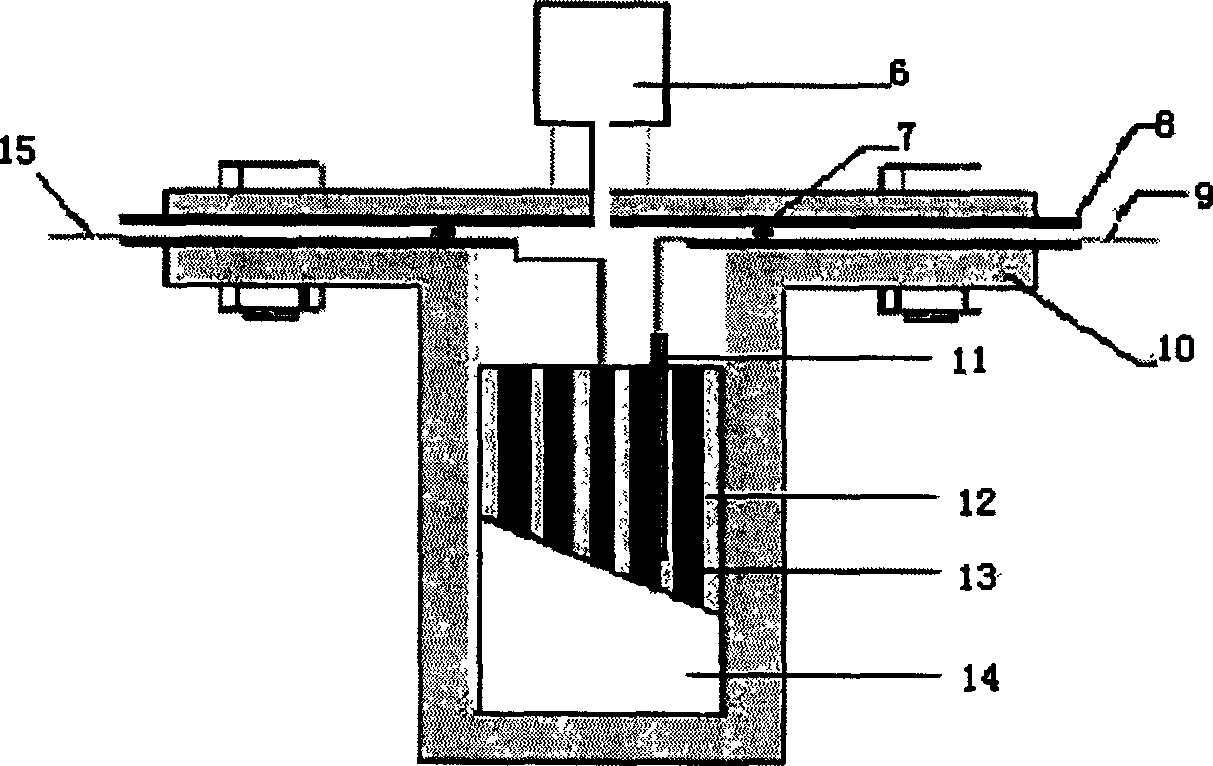

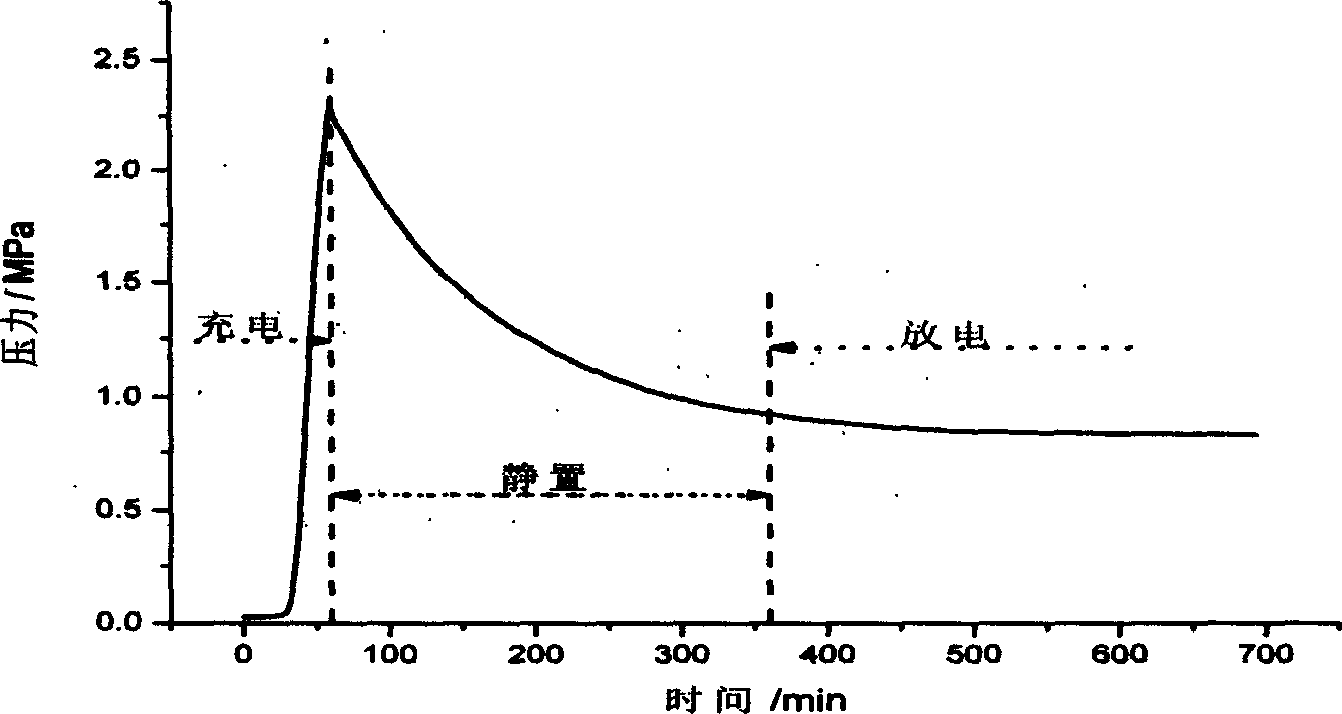

[0019] Below in conjunction with accompanying drawing, the nickel-cadmium secondary battery of the present invention is illustrated in detail

[0020] Weigh 80 parts by weight (weight fraction, the same below) of CdO powder, 20 parts of Cd powder, 2 parts of Ni(OH) 2 , 6 parts of Ni powder, 0.3 parts of acetylene black, 5 parts of CMC, 2.5 parts of PVA, 5 parts of H 2 O, 2 parts of PTFE, mixed and stirred, filled into foamed nickel or coated on a porous steel strip, dried and compacted to make a cadmium negative electrode sheet; another 95 parts of MmNi were weighed 5 series of MmNi 3.55 co 0.75 mn 0.4 Al 0.3 Hydrogen storage alloy powder, 4 parts of carbon powder or acetylene black, 1 part of CMC or 1 part of HPMC, 1 part of SBR mixed with water, filled in foamed nickel or coated on a porous steel strip, made of the same height as the cadmium negative plate The equal hydrogen storage alloy negative electrode sheet is then cut into small pieces of certain length (the prop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com