Reverse osmosis method for treating sewage

A sewage treatment method and reverse osmosis technology, which are applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

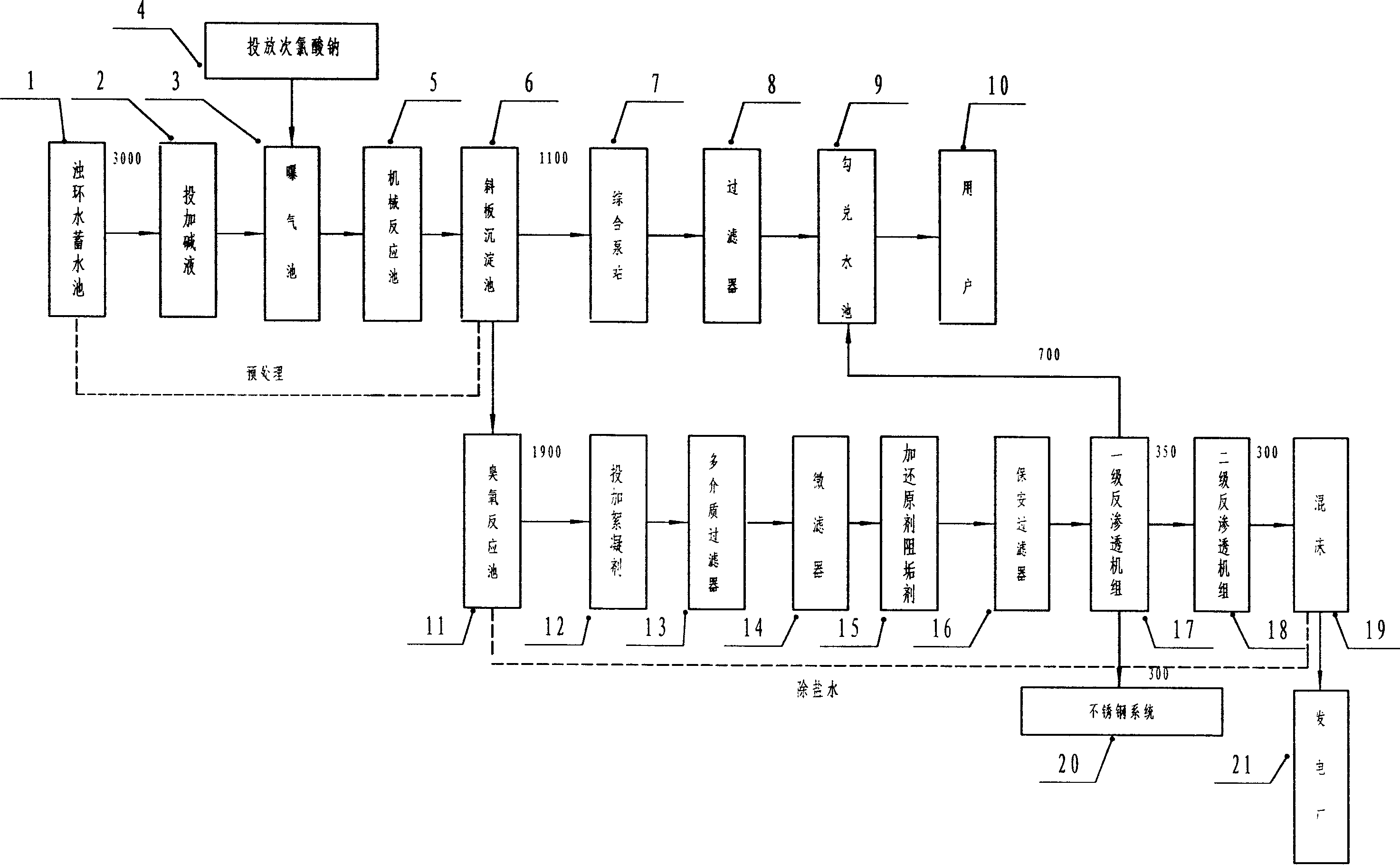

[0015] The detailed process of the reverse osmosis sewage treatment method of the present invention will be described below through examples and accompanying drawings, but the reverse osmosis sewage treatment method is not limited to the following examples.

[0016] For the flow process of the sewage treatment method embodiment of the present invention, see figure 1 .

[0017] Discharge the turbid ring water, the waste water after primary treatment, to the turbid ring water reservoir 1. The water quality of the turbid ring water is shown in Table 1.

[0018] project

SS

Oil

Fe

pH

COD

parameters

100-500

20-40

10-30

2-11

2000-3000

38-240

[0019] The unit of SS, Oil, Fe and COD is mg / l, and the unit of salt content is us / cm; first measure the pH value of the turbid ring water, when the pH value is acidic, the flocculation effect of the flocculant is poor. There is a water diversion ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com