Dedicated lubricating liquid for rolling cupper and copper alloy and its prepn. method

A technology of lubricating liquid and copper alloy, applied in lubricating compositions, petroleum industry, base materials, etc., can solve problems such as copper strip corrosion and discoloration, residual stains on the strip surface, and difficult stability of component emulsification and dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

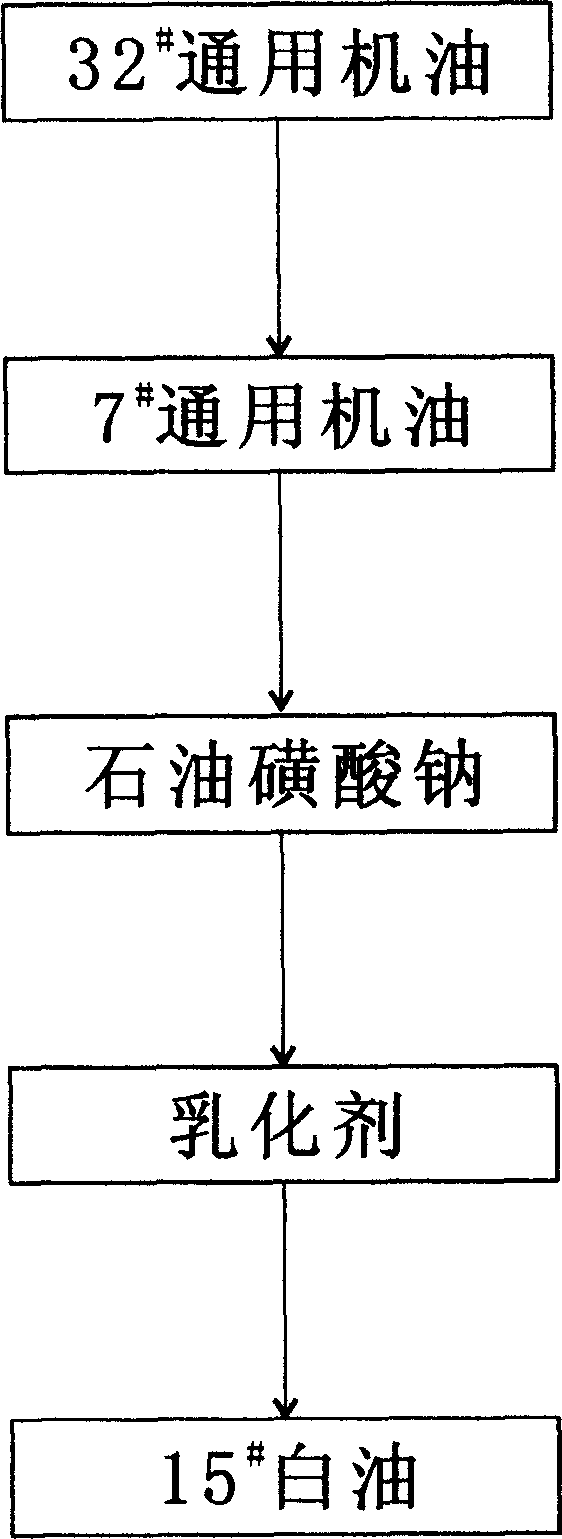

[0014] When the copper product grade is TFE0.1 and the batch number is 0661032 strip, the thickness of the entrance is 14.0mm, and the thickness of the exit is 1.5mm, and the rolling is completed in 7 rolling passes. It is made by mixing 11% of 32# general-purpose engine oil, 55% of 7# general-purpose engine oil, 8% of sodium petroleum sulfonate, 11% of emulsifier, and 7% of white oil. In the preparation of lubricating fluid, first add 7# general-purpose motor oil to 32# general-purpose motor oil; then add sodium petroleum xanthate; then add emulsifier; then add 15# white oil; keep stirring and heating during the preparation. The temperature is controlled between 30°C and 50°C; according to the rolling conditions, add 95% deionized water and keep stirring and heating, the heating temperature is controlled between 30°C and 50°C, and finally formulated into a certain concentration of emulsified liquid for rolling. From the first rolling pass to the finished product, the emulsio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com