Health lens for preventing blue light harm and its mfg. method

An anti-blue light, spectacle lens technology, applied in glasses/goggles, optics, optical components, etc., can solve the problems of high light quantum energy level, poor visual and color discrimination performance, limited color discrimination ability, etc., to achieve soft color discrimination. , the effect of clear vision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

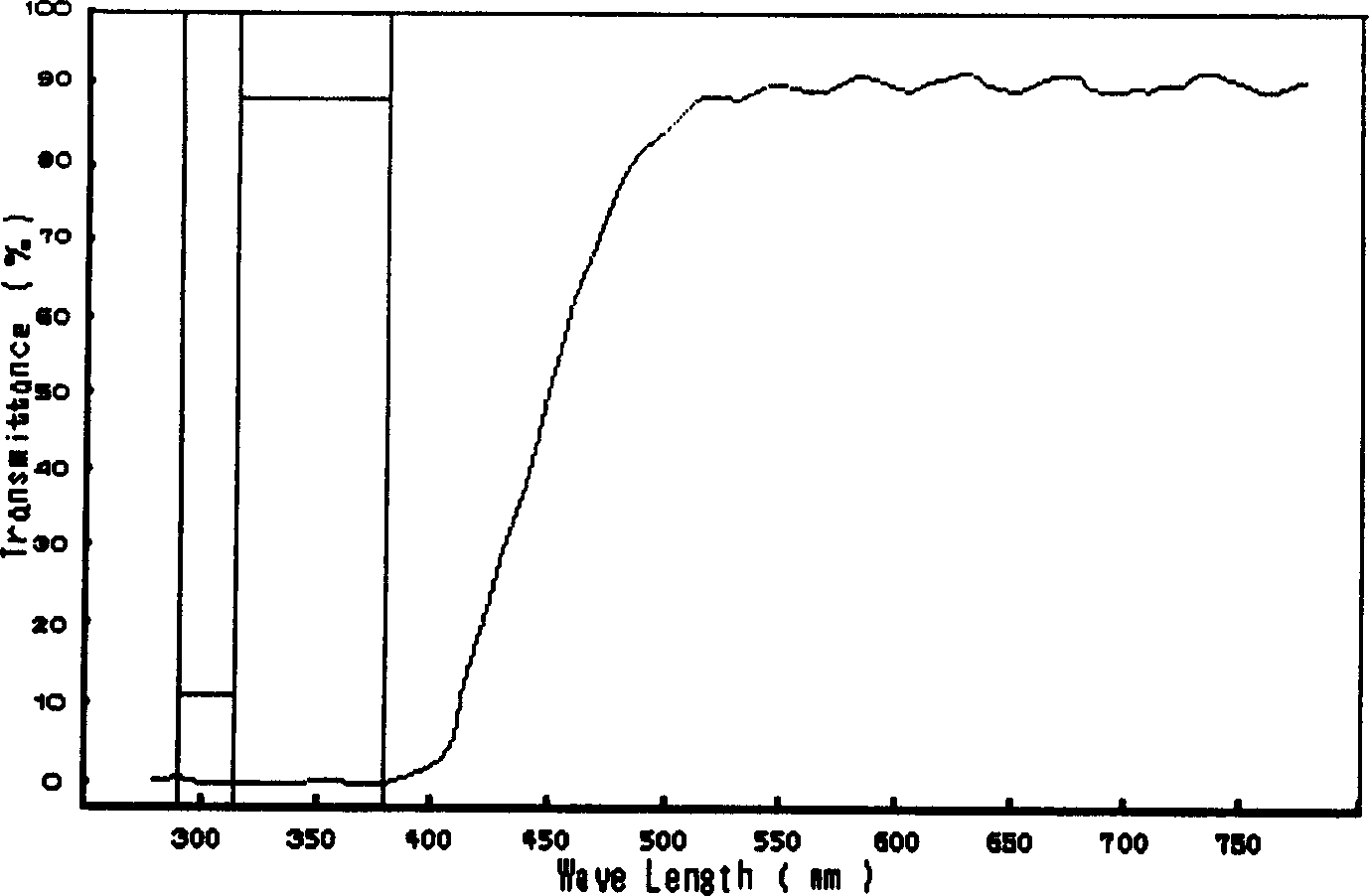

[0051] Such as Figure 7 As shown, the anti-blue light damage health care spectacle lens in this specific embodiment is composed of two parts: a substrate 1 and an evaporated film layer. Substrate 1 is a refractive lens prepared from polycarbonate containing a short-wave visible light absorber, or may be made of polymethyl methacrylate or allyl diglycol carbonate and diisopropyl alcohol containing a short-wave visible light absorber. Refractive lenses prepared from any one of the peroxycarbonate copolymers. The vapor-deposited film layer is composed of three layers of alternately stacked layers, from the inside to the outside are SiO 2 Film layer 2, ZrO film layer 3 and SiO 2 The film layer 4 has a thickness of 138nm, 275nm and 138nm respectively.

[0052] SiO in this specific embodiment 2 Coating 2 and SiO 2 The film layer 4 is a low refractive index film layer, and the ZrO film layer 3 is a high refractive index film layer.

[0053] The short-wave visible light absorbe...

specific Embodiment 2

[0055] The anti-blue light damage health care spectacle lens in this specific embodiment consists of two parts: a substrate and an evaporated film layer. The substrate is a refractive lens made of polymethyl methacrylate containing a short-wave visible light absorber, or it can be made of polycarbonate or allyl diglycol carbonate and diisopropyl peroxide containing a short-wave visible light absorber. Refractive lenses prepared from any one of the oxidized carbonate copolymers. The vapor-deposited film layer is composed of five layers of film layers stacked alternately, from the inside to the outside are respectively TiO 2 film, SiO 2 Film layer, TiO 2 film, SiO 2 film and TiO 2 The film layer has a thickness of 197nm per layer.

[0056] The short-wave visible light absorber in this specific example is formed by mixing disperse yellow and disperse blue. The short-wave visible light absorber in this specific embodiment can also be disperse yellow, or a mixture of disperse...

specific Embodiment 3

[0057] The anti-blue light damage health care spectacle lens in this specific embodiment consists of two parts: a substrate and an evaporated film layer. The substrate is a refractive lens made of allyl diglycol carbonate and diisopropyl peroxycarbonate copolymer containing short-wave visible light absorbers, or it can be made of polycarbonate or polycarbonate containing short-wave visible light absorbers. Refractive lenses prepared from any one of methyl methacrylate. The vapor-deposited film layer is composed of seven layers alternately stacked, from the inside to the outside are CoO film, SiO 2 film, CoO film, SiO 2 film, CoO film, SiO 2 The film layer and the CoO film layer, the thickness of the inner 4 film layers is 100nm, and the thickness of the outermost 3 film layers is 120nm.

[0058] The short-wave visible light absorber in this specific example is formed by mixing disperse yellow, disperse blue and disperse black. The short-wave visible light absorber in this ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com