Method for producing photochromic composite film and the product thereby

A composite film, visible light technology, applied in the direction of color-changing fluorescent materials, chemical instruments and methods, devices for coating liquids on the surface, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Concentration is 5% PVP (produced by U.S. Aldrich company, number average molecular weight is 100000, purity 99%) aqueous solution is mixed with 2% molybdic acid aqueous solution, mixing ratio is 1: 10, under 15 ℃, stir 2 hours, will prepare The obtained sol was prepared into a thin film by casting method. The film has good visible photochromic performance, and the film changes from light yellow to blue when irradiated with visible light (λ > 420nm) for 30 minutes, and the change in the ultraviolet-visible spectrum at 780nm reaches 0.1.

Embodiment 2

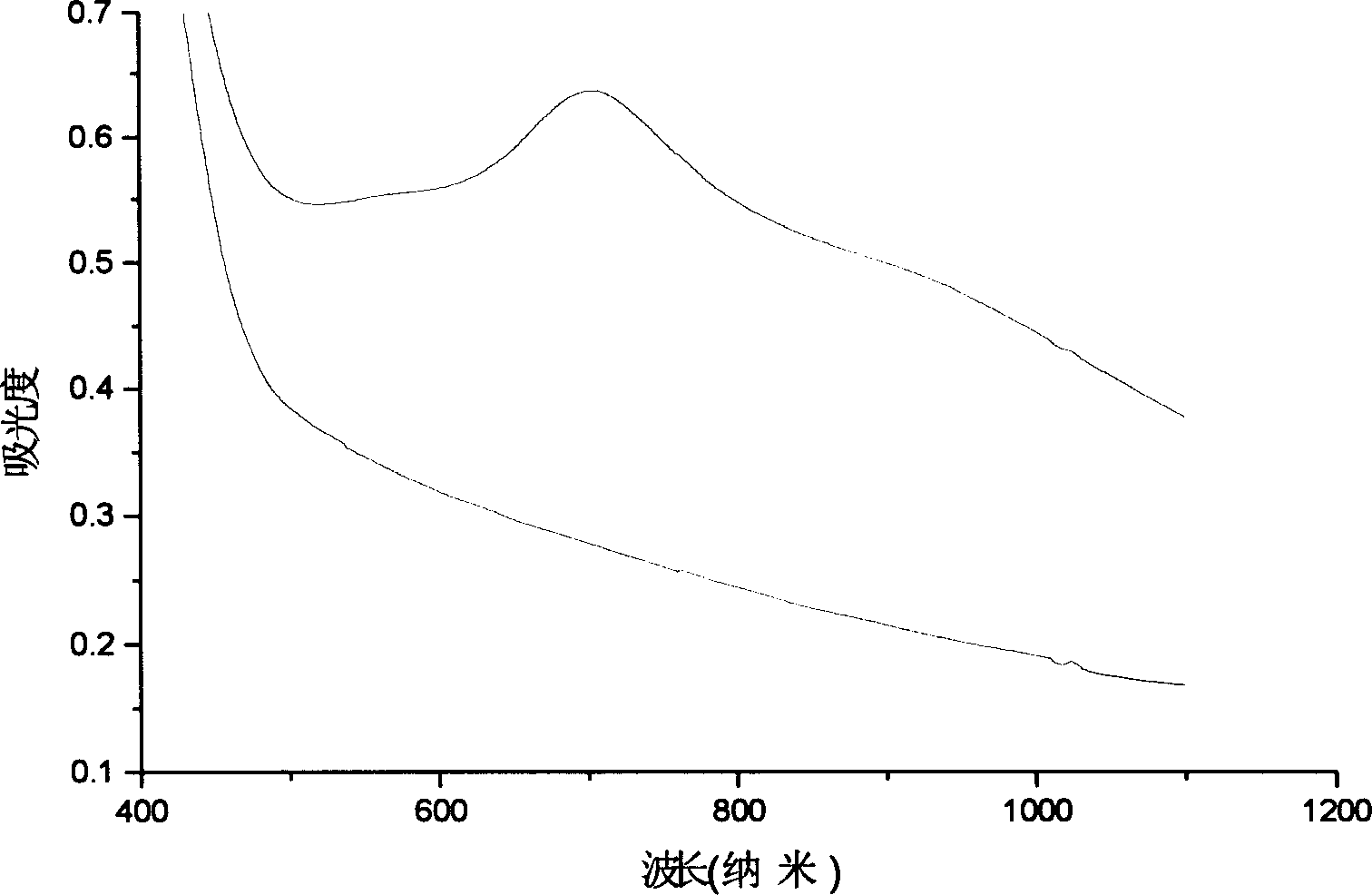

[0023] Concentration is 10% PVA (produced by U.S. Aldrich company, number-average molecular weight is 100000, purity 99%) aqueous solution is mixed with 10% phosphomolybdic acid aqueous solution, mixing ratio is 1: 5, stirs 5 hours under 20 ℃, will prepare The obtained sol was prepared into a thin film by casting method. The prepared film has good photochromic properties of visible light. When irradiated with visible light (λ>420nm) for 60 minutes, the film changes from light yellow to light blue, and its absorption change at 780nm on the ultraviolet-visible spectrum can reach 0.3, such as figure 1 shown.

Embodiment 3

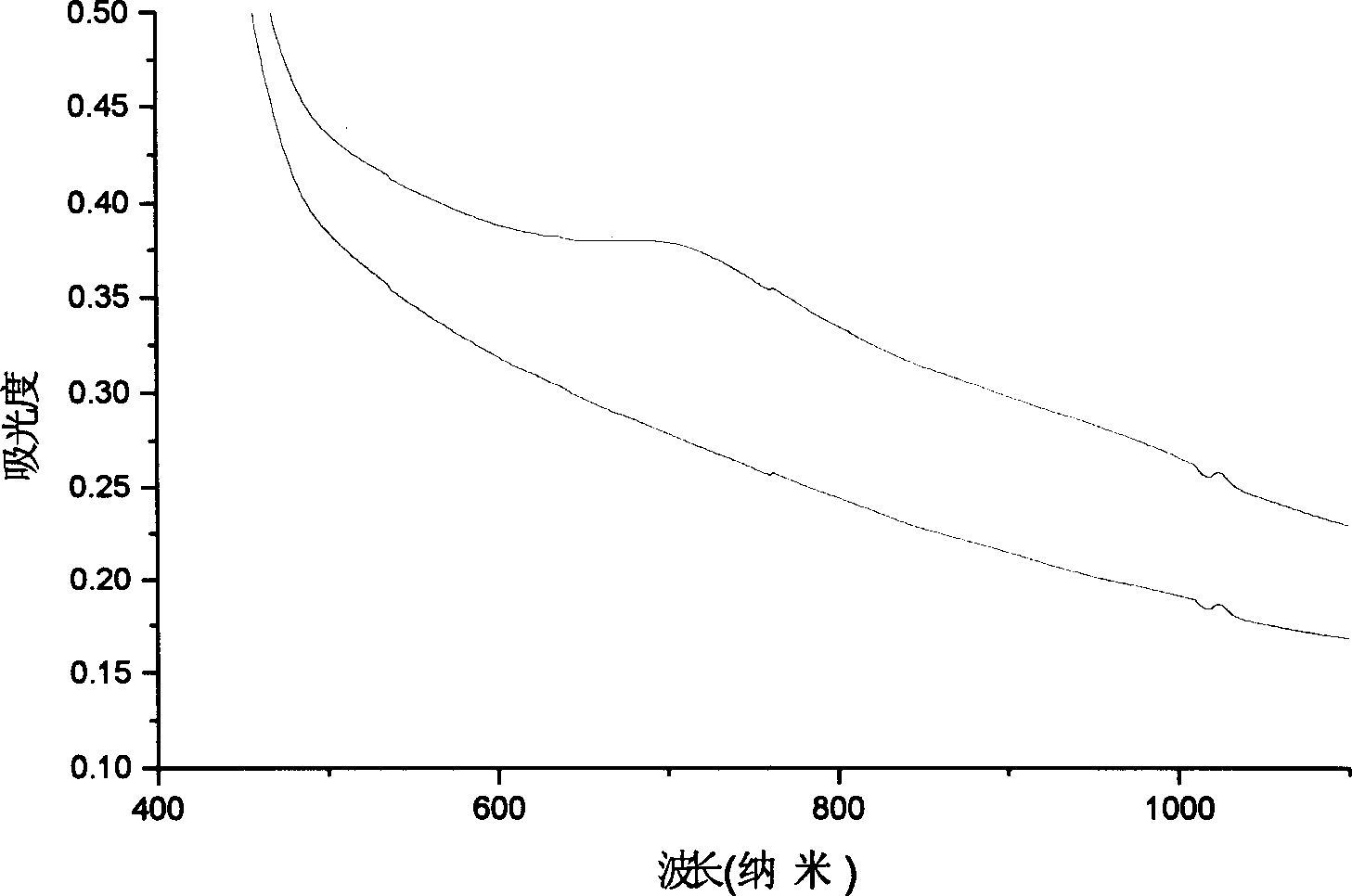

[0025] A 15% concentration of PAM (produced by Aldrich, USA, with a number average molecular weight of 100,000 and a purity of 99%) was mixed with a 13% aqueous solution of sodium molybdate in a mixing ratio of 5:1, stirred at 30°C for 8 hours, and the obtained The sol is prepared into a thin film by spin coating, and the film has good photochromic properties of visible light. When irradiated with visible light (λ>420nm) for 60 minutes, the film changes from light yellow to light blue. The absorption change at 780nm on the spectrum can reach 0.1, such as figure 2 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com