Method and structure for forming barrier layer

A barrier layer and object layer technology, applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as damaging semiconductor components, affecting the electrical properties of the dielectric layer, and reducing the resistivity of the barrier layer 190

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Some embodiments of the present invention are described in detail as follows. However, the invention can be broadly practiced in other embodiments than those described in detail. That is, the scope of the present invention is not limited by the proposed embodiments, but should be defined by the scope defined in the following claims.

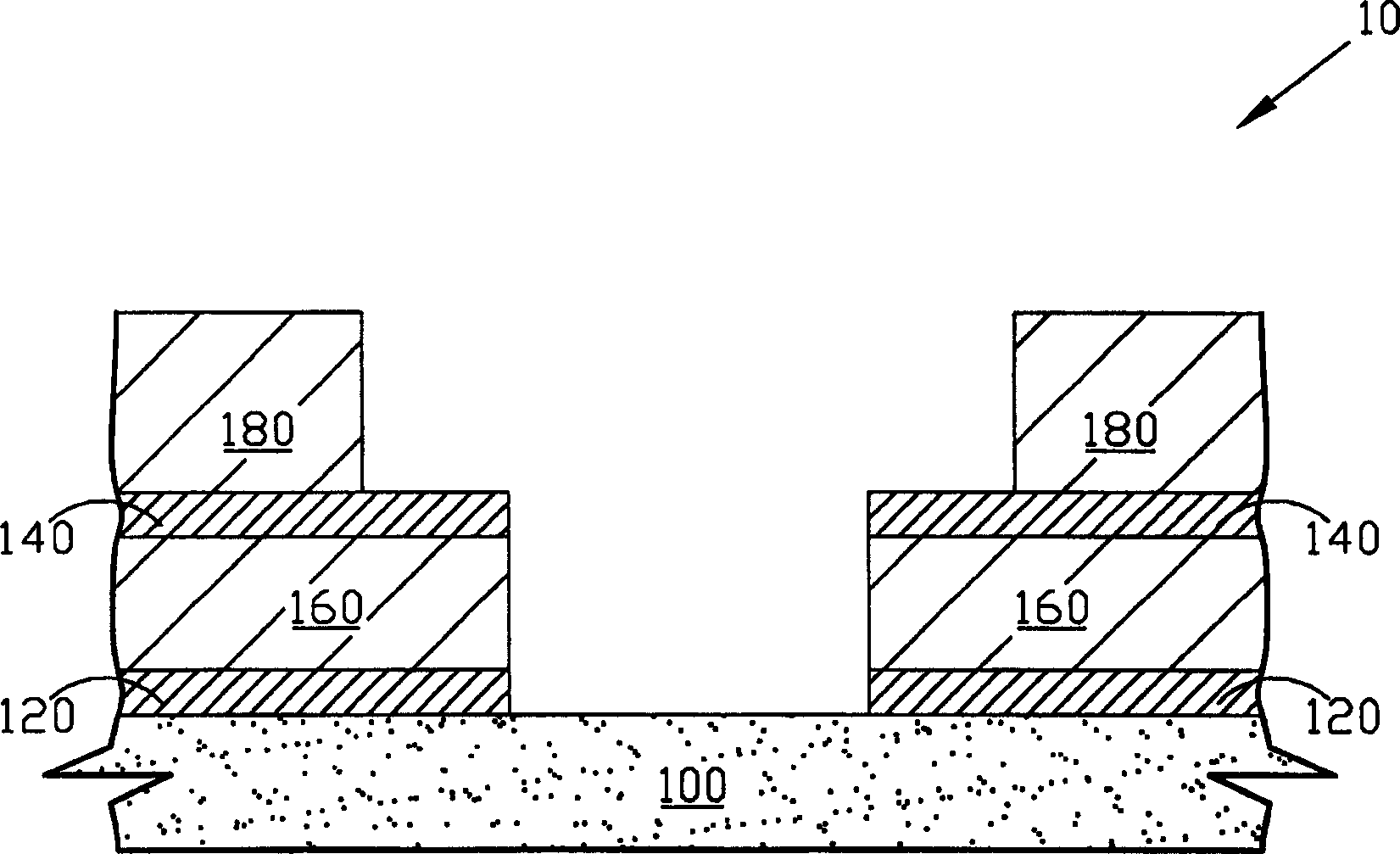

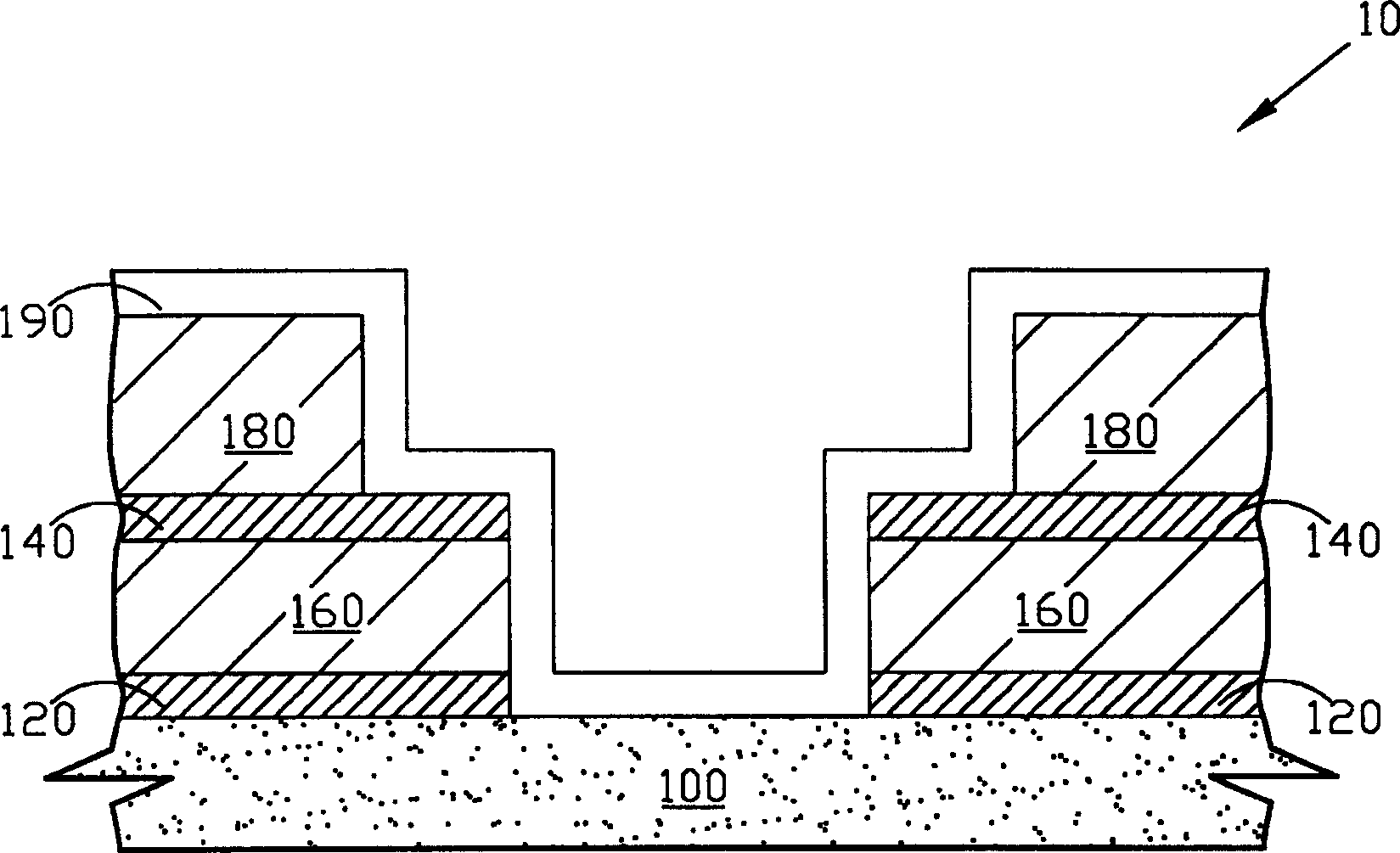

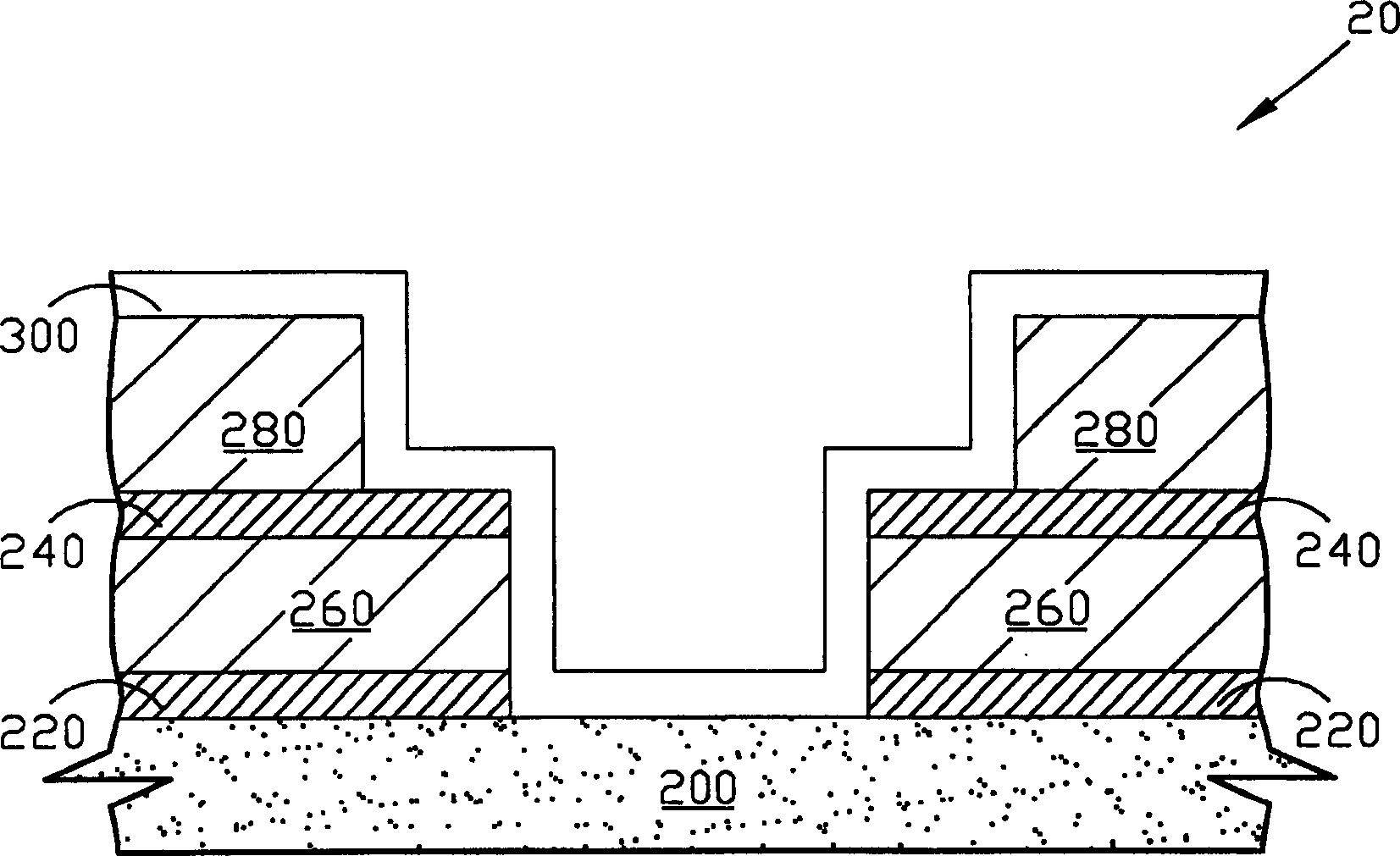

[0016] In the first embodiment of the present invention, as Figure 2A As shown in ~E, a dual damascene structure 20 has been formed above a metal layer 200 of a wafer. This dual damascene structure 20 is composed of a first etch stop layer 220, a first dielectric layer 260 above the first etch stop layer 220, The second etch stop layer 240 above the first dielectric layer 260 and the second dielectric layer 280 above the second etch stop layer 240 are formed, wherein the metal layer 200 is a copper metal layer, and the first etch stop layer 220 The material of the second etch stop layer 240 is to prevent copper metal atoms from diffusin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com