Method and equipment for treatment of polluted fluid

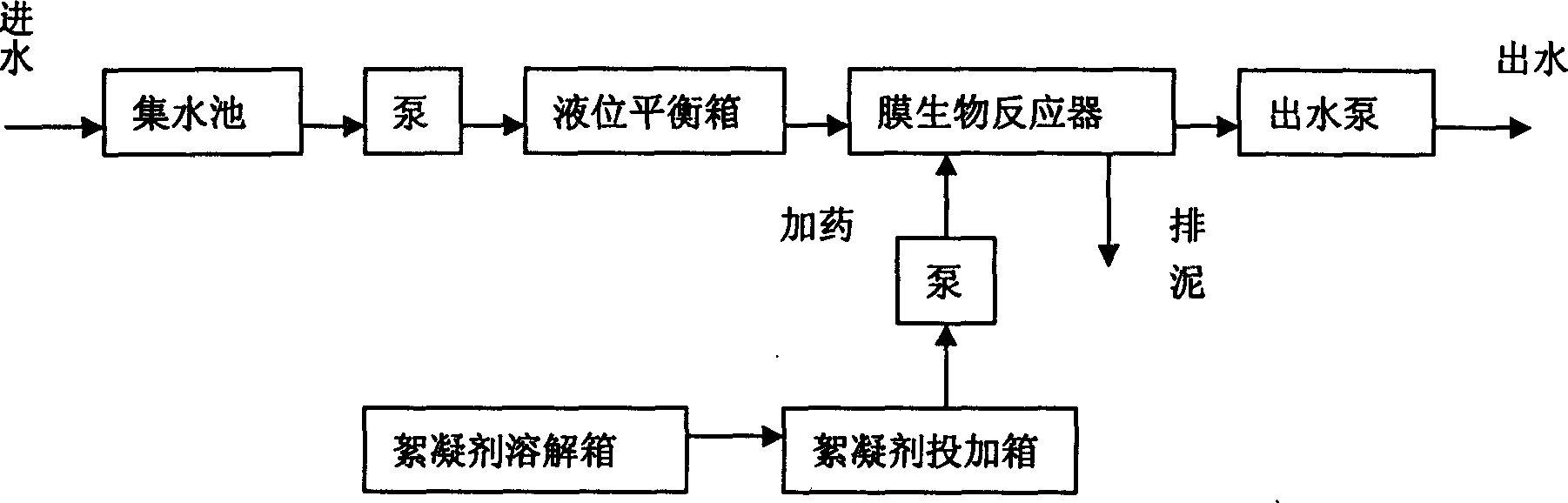

A treatment method and fluid treatment technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, sustainable biological treatment, etc., can solve unstable effluent water quality, serious membrane pollution, large floor area, etc. problems, to achieve the effect of good water quality, good water quality, and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

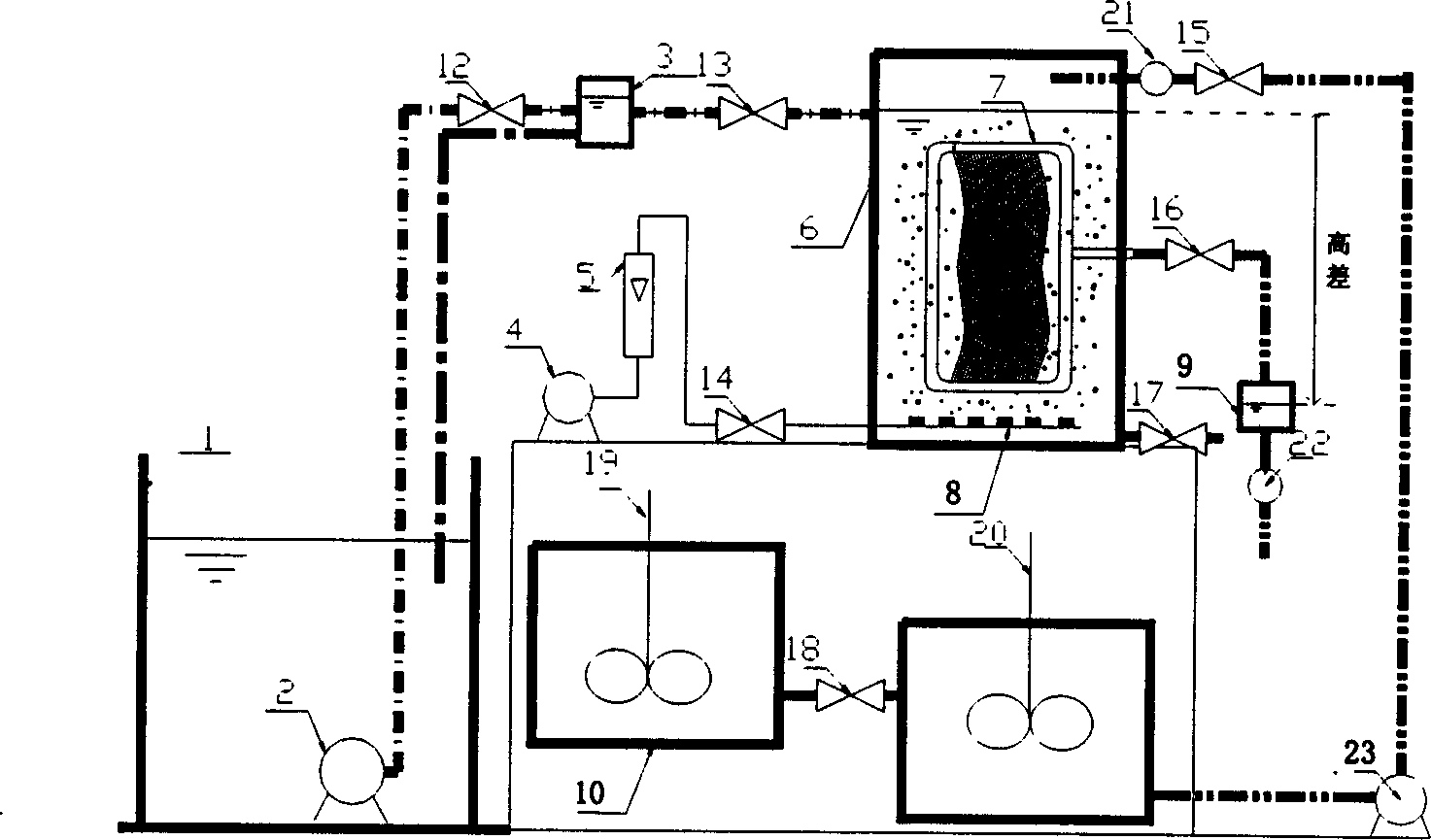

Method used

Image

Examples

Embodiment 1

[0024] Starch wastewater is treated in the following ways:

[0025] (1) Ferrous sulfate is added in the bioreactor, and the concentration of the solution in the reactor is 700mg / L, domesticated to form bio-iron sludge, and the pollutants are condensed into particles;

[0026] (2) Use the activated sludge in the bioreactor to carry out biochemical action to remove the pollutants in the polluted fluid. The hydraulic retention time of the operation is 10 hours, the sludge age is 20 days, and the sludge concentration is stable at 7g / L;

[0027] (3) Use polyvinylidene fluoride 0.2 μm hollow fiber membrane module for filtration;

[0028] (4) Recycled cleaning fluid is obtained.

[0029] project

[0030]

Embodiment 2

[0032] Use the following methods to treat printing and dyeing wastewater (alkali-containing waste water):

[0033] (1) Ferric hydroxide is added in the bioreactor, the concentration of the solution in the reactor is 175mg / L, domesticated to form bio-iron sludge, and the pollutants are condensed into particles;

[0034] (2) Use the activated sludge in the bioreactor for biochemical action to remove the pollutants in the polluted fluid. The hydraulic retention time of the operation is 15 hours, the sludge age is 20 days, and the sludge concentration is stable at 3.5g / L;

[0035] (3) Use polyvinylidene fluoride 0.2 μm hollow fiber membrane module for filtration;

[0036] (4) Recycled cleaning fluid is obtained.

[0037]

Embodiment 3

[0039] Domestic sewage is treated in the following ways:

[0040] (1) Ferric chloride is added in the bioreactor, the concentration of the reactor is 40mg / L, domesticated to form biological iron sludge, and the pollutants are condensed into particles;

[0041] (2) Use the activated sludge in the bioreactor to carry out biochemical action to remove the pollutants in the polluted fluid. The hydraulic retention time of the operation is 6 hours, the sludge age is 100 days, and the sludge concentration is stable at 4g / L;

[0042] (3) The membrane module adopts polyvinylidene fluoride 0.2μm hollow fiber membrane module;

[0043] (4) Recycled cleaning fluid is obtained.

[0044]

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com