Enzymolytic preparation method for glossy ganoderma amylose

A technology of Ganoderma lucidum polysaccharide and enzymolysis, which is applied in the production field of active Ganoderma lucidum polysaccharide content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

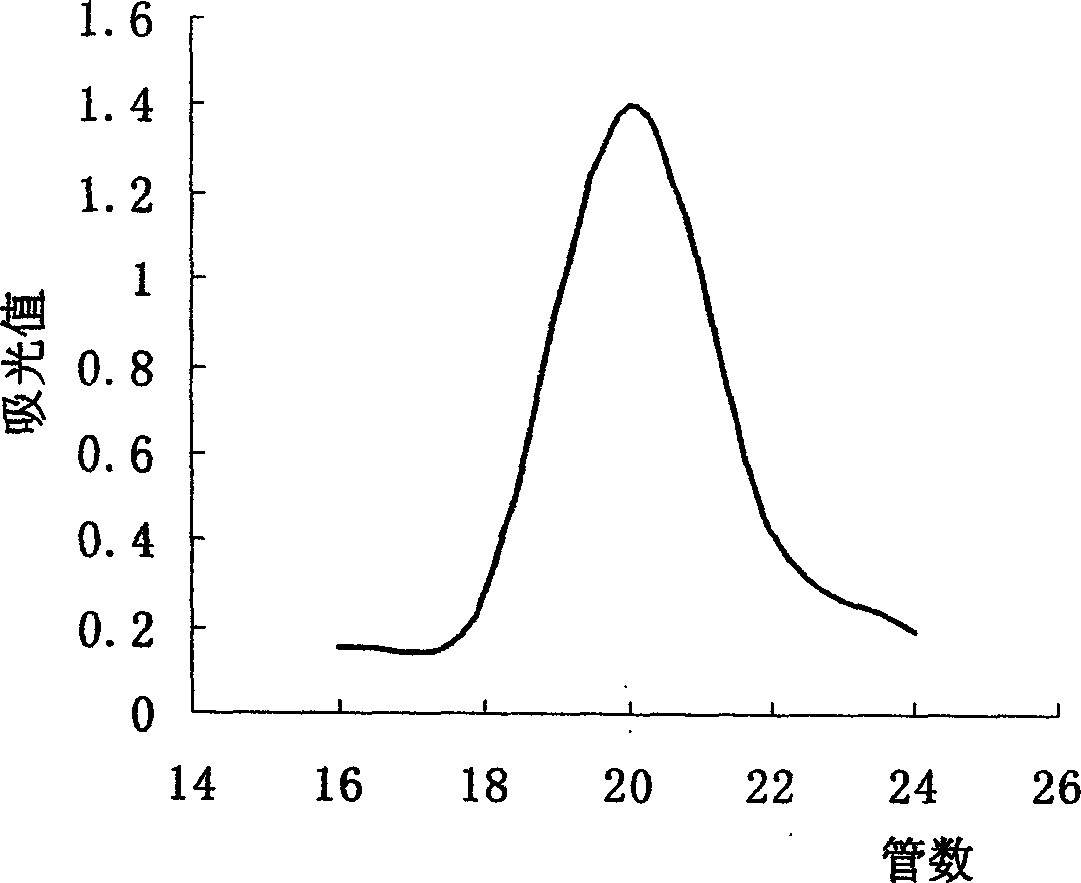

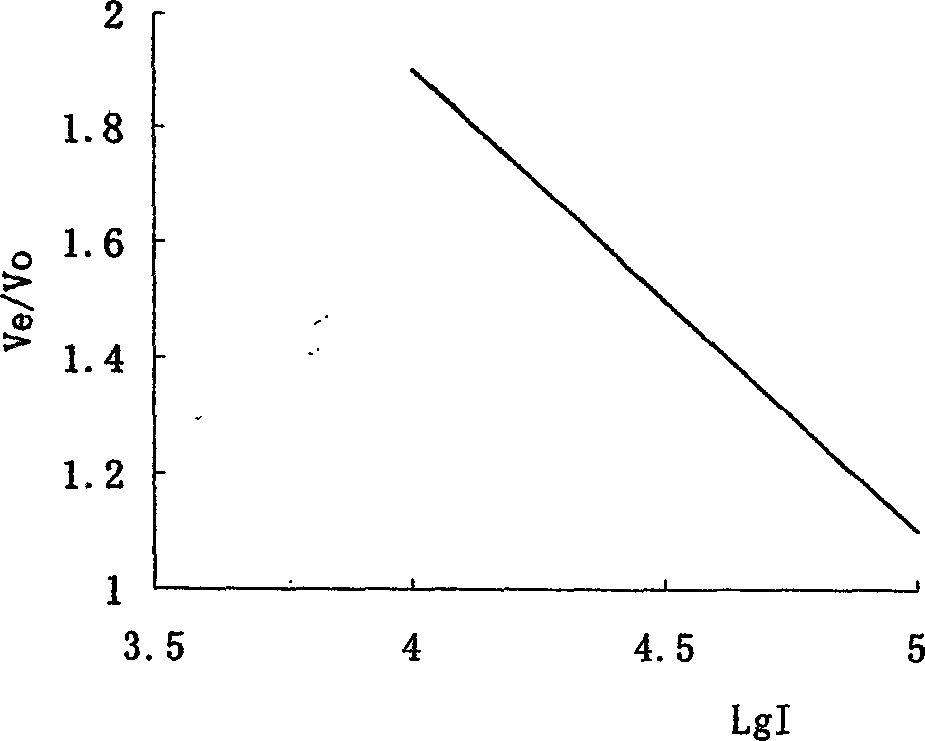

Image

Examples

Embodiment 1

[0025] 10 tons of fermented liquid Ganoderma lucidum polysaccharide enzyme treatment method

[0026] (1) Obtain Ganoderma lucidum liquid submerged fermentation broth by step-by-step expansion of slant strains: connect the ganoderma lucidum slant strains into 500 ml shake flasks with 100 ml medium for primary seed cultivation, culture conditions: rotary shaker 150 rpm, 28°C for 50 hours. Then the seeds of the primary shake flask were inserted into a 500 ml shake flask equipped with 100 ml of medium with 10% inoculum to carry out secondary seed culture, and cultivated according to the same conditions as the primary shake flask. Then with 10% inoculum size, the secondary seeds are transferred into the 5000 milliliter shake flasks with 1000 milliliters of medium to carry out the three-stage seed cultivation, culture conditions: 180 rpm of rotary shaker, cultivated for 50 hours at 28°C . Then with 10% inoculum size, the third-level seeds are inserted into the first-level seed tan...

Embodiment 2

[0046] Embodiment 2 (10 tons of fermented liquid)

[0047] A kind of method that enzymolysis prepares Ganoderma lucidum polysaccharide, its step is the same as embodiment 1:

[0048] During the enzymatic hydrolysis process of the mycelium itself, the fermentation broth is adjusted to make its pH 5.5. At 45°C, the Ganoderma lucidum mycelium in the fermentation broth is enzymolyzed with the help of its own enzyme system existing in the Ganoderma lucidum mycelium. Solution for 70 minutes, stirring speed 40 rpm;

[0049] In the enzymatic hydrolysis process with external enzymes, at 50°C and pH 5.5, add mixed enzymes to the fermentation broth: 0.15 kg of cellulase, 1.2 kg of β-glucanase, 0.9 kg of pectinase, neutral Protease 0.75 kg, enzymolysis time 2 hours, stirring speed 40 rpm;

[0050] During the enzyme inactivation process, the fermentation broth was heated to 90°C for 10 minutes to inactivate the enzyme;

[0051] During the concentration process, the filtrate was concentr...

Embodiment 3

[0053] Embodiment 3 (10 tons of fermented liquid)

[0054] A kind of method that enzymolysis prepares Ganoderma lucidum polysaccharide, its step is the same as embodiment 1:

[0055] During the enzymatic hydrolysis process of the mycelium itself, adjust the fermentation broth to make it pH 5, and at 30°C, enzymolyze the Ganoderma lucidum mycelium in the fermentation broth with the help of the self-enzyme system existing in the ganoderma lucidum mycelium. Solution for 30 minutes, stirring speed 60 rpm;

[0056] In the enzymatic hydrolysis process with external enzymes, at 30°C and pH 6.0, add mixed enzymes to the fermentation broth: 0.2 kg of cellulase, 1.6 kg of β-glucanase, 1.2 kg of pectinase, neutral Protease 1 kg, enzymolysis time 2.5 hours, stirring speed 50 rpm;

[0057] In the process of inactivating the enzyme, the fermented liquid is heated to 100°C for 30 minutes to inactivate the enzyme;

[0058] During the concentration process, the filtrate was concentrated to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com