Electrical control upright arrangement integrated pump / valve - pipe - nozzle spraying system

An in-line combination, injection system technology, applied in the charging system, electrical control, fuel injection control, etc., can solve the impossible control of fuel injection rate and fuel injection pressure, cannot directly change the fuel quantity and timing, and cannot achieve various Cylinder sub-cylinder control and other issues, to achieve the effect of being beneficial to system transplantation, simple structure, and simplified oil pump structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The specific structure, working principle and preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

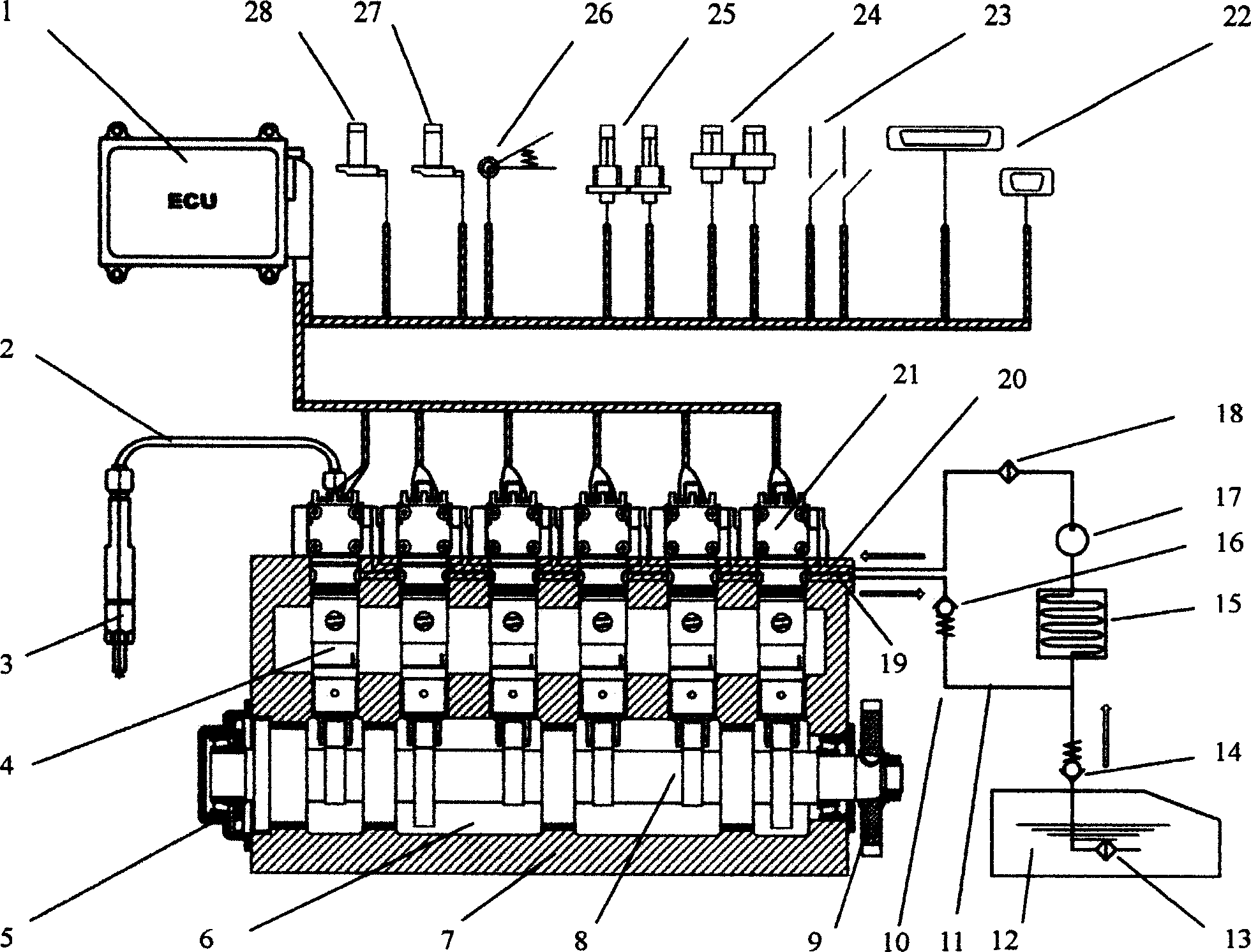

[0012] figure 1 Shown is the overall structure diagram of the electronically controlled inline combined pump / valve-pipe-nozzle diesel injection system. It mainly includes five functional modules: electronic control unit 1, in-line combined pump / valve device 6, high-pressure fuel pipe 2, fuel injector 3, and low-pressure fuel device 10:

[0013] The electronic control unit 1 consists of control system hardware based on a 32-bit single-chip microcomputer, engine management system software, a camshaft position sensor 28 installed on the pump body, a crankshaft position sensor 27 installed on the engine flywheel housing, and a crankshaft position sensor 27 installed on the accelerator pedal. The accelerator position sensor 26 is composed of various temperature sensors 25, pressure sensors 24, signal switch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com